Antimicrobial phase-separable glass/polymer articles and methods of making the same

A technology of anti-microbial and anti-microbial reagents, applied in botany equipment and methods, chemical instruments and methods, biocides, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

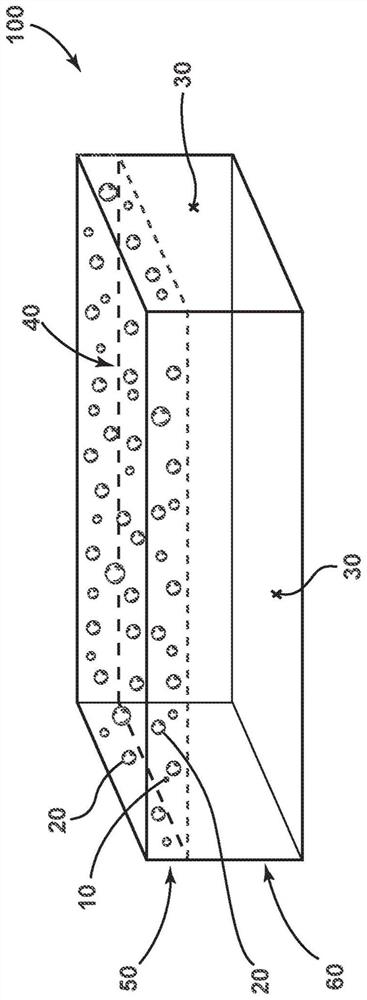

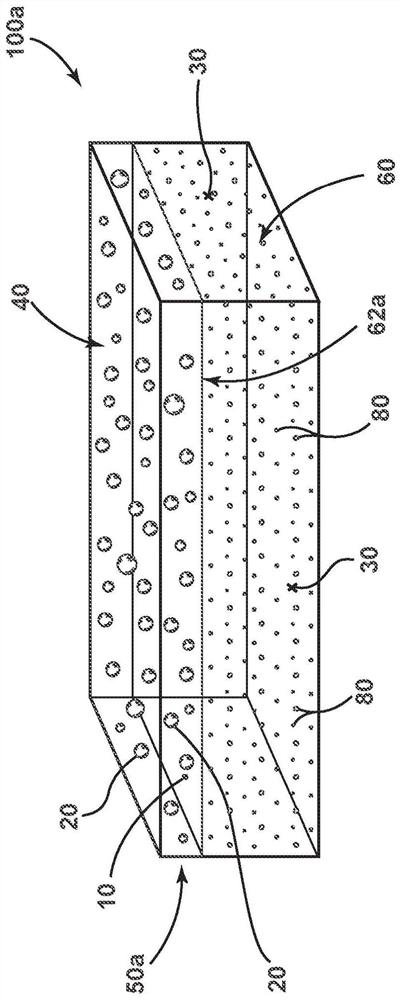

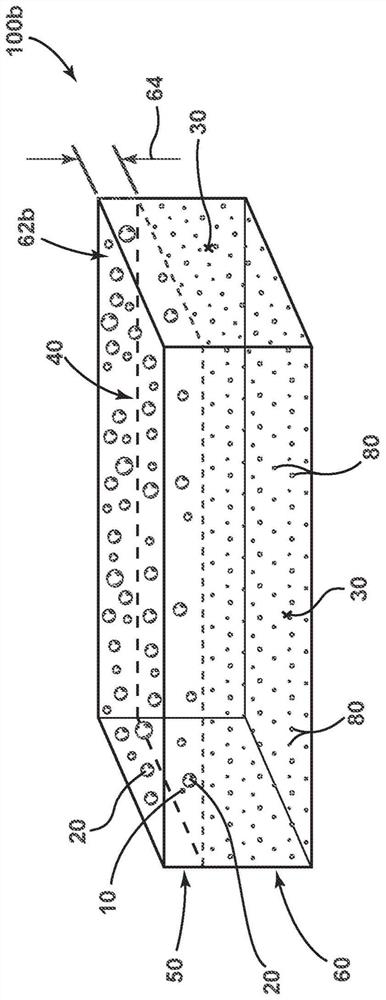

[0101] Various polymers were used as matrix materials to fabricate antimicrobial composite films by extrusion process. These membranes are used for Figure 1A The antimicrobial composite film 50a of the illustrated antimicrobial article 100a is comparable. Tables 1 and 2 below summarize the materials and process conditions used to make these films. Prior to each run listed in Table 2, a particular polymer (eg, Polymer 1) was hand mixed with copper phase-separable glass in a bag prior to placement in the extruder. Next, the mixture of polymer and copper glass particles was put into an extruder, which was then used to extrude an antimicrobial composite film. In this example, a Leistritz AG MIC18-7R GL twin-screw extruder (2.5 cm) was used to produce films according to the conditions listed in Table 2. The resulting product from the extruder was directed through a 5 cm wide film and a set of rollers / windup elements to form each film. Such as Figure 4A As shown, "Batch 3" in...

Embodiment 2

[0109] In this example, polycarbonate membranes (without phase-separable glass) were prepared according to "Batch 1" of Table 2 and the conditions listed in Example 1 above. Once the polycarbonate film was extruded through a die at approximately 290°C, it was rolled to final thickness at 140°C and stamped into the copper glass listed in Table 1 above.

Embodiment 3

[0111] see Figure 5 , the histogram showing the antimicrobial efficacy of the antimicrobial composite films from Examples 1 and 2 above (tested according to the modified EPA copper test protocol). Specifically, "Example 5-1" corresponds to "Lot 1" of Example 2, ie, copper glass imprinted polycarbonate. "Example 5-2" corresponds to "batch 2" of Example 1, that is, a polypropylene / copper glass composite film co-extruded from polypropylene and copper glass. Finally, Examples "5-3" correspond to "Batch 3" of Example 1, ie a polypropylene / copper glass / carbon black composite film in which polypropylene, copper glass and carbon black were co-extruded into a final film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com