Production method for a resistor, resistor and corresponding production installation

A manufacturing method and technology of resistors, applied in the direction of resistor manufacturing, resistors, trimmer resistors, etc., can solve the problem that the manufacturing method is not optimal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

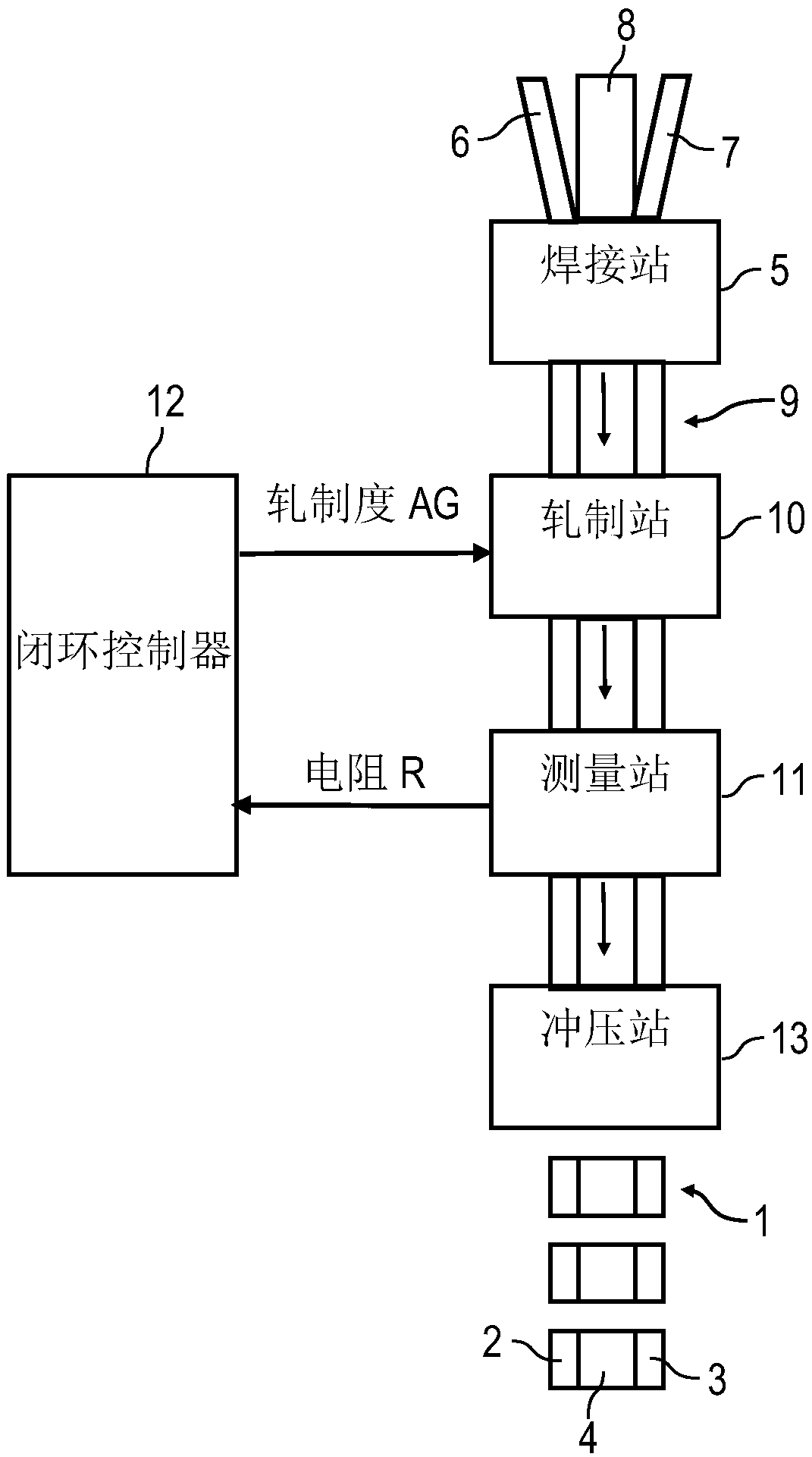

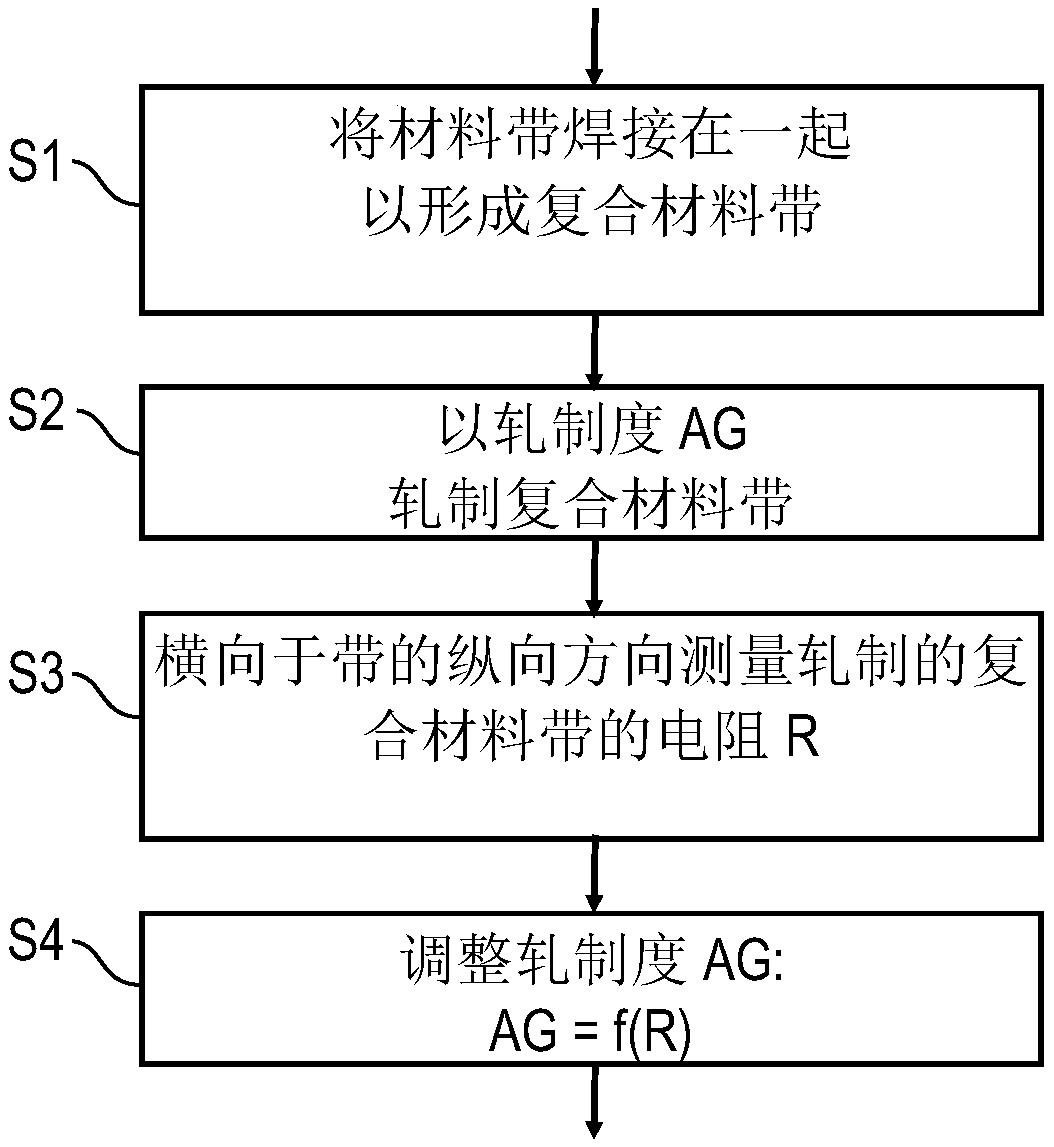

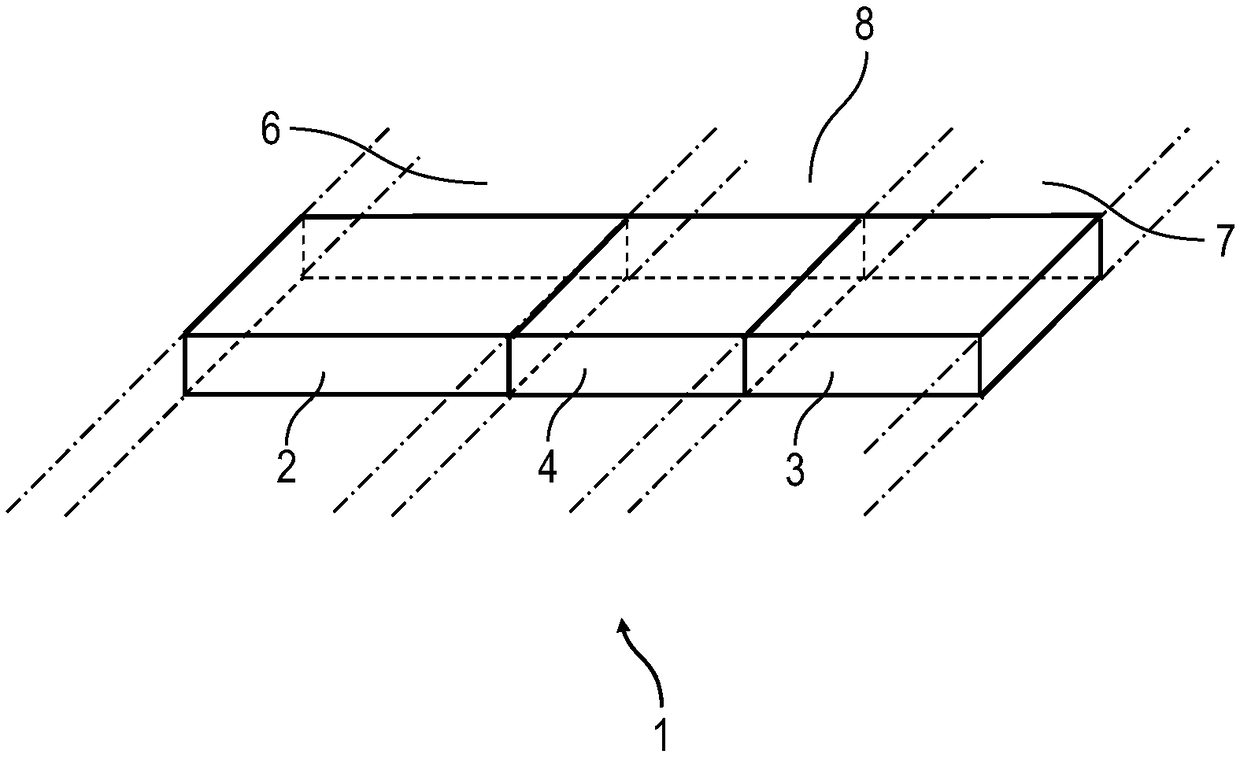

[0057] figure 1 A schematic view of a production installation according to the invention for producing a low-resistance current-measuring resistor 1 as known in a similar form from EP 0 605 800 A1 is shown. The current-measuring resistor 1 consists of two plate-shaped connections 2, 3 made of copper or another conductive material and made of a resistor material such as The fabricated resistor element consists of 4. The resistor element 4 is arranged between the two connections 2 , 3 in the direction of current flow, whereby the connections 2 , 3 are used to introduce the current to be measured into the current-measuring resistor 1 or to let the current flow out of the current-measuring resistor .

[0058] To produce the current-measuring resistor 1, two copper strips 6, 7 and a resistor strip 8 are supplied to the welding station 5, where the copper strips 6, 7 and the resistor strip 8 are then welded along their longitudinal edges in the welding station 5. Together, to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com