Self-propelled silage harvester

A green forage harvester, self-propelled technology, applied in the field of self-propelled green forage harvester, can solve problems such as blade chipping, affecting efficiency, and complicated power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

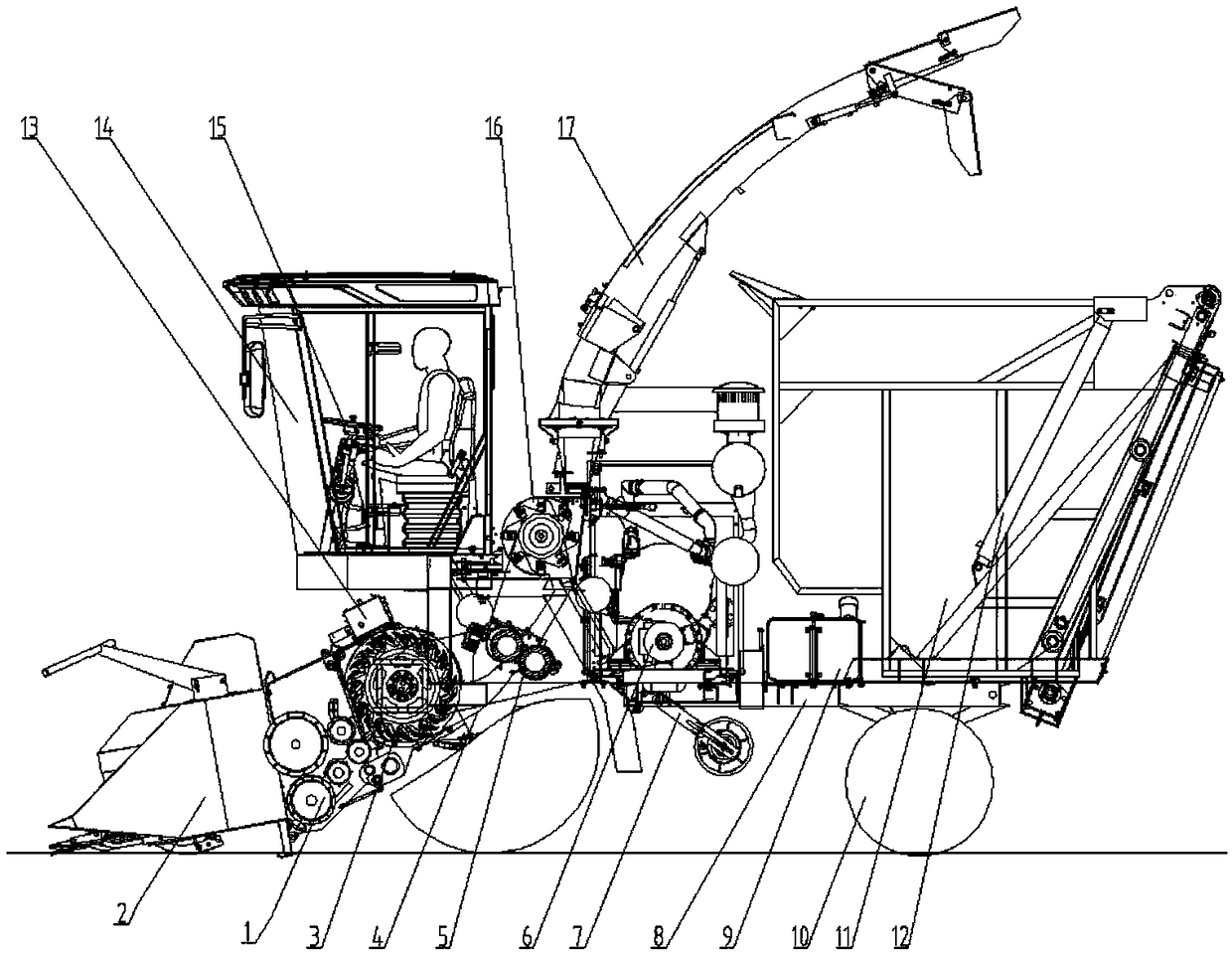

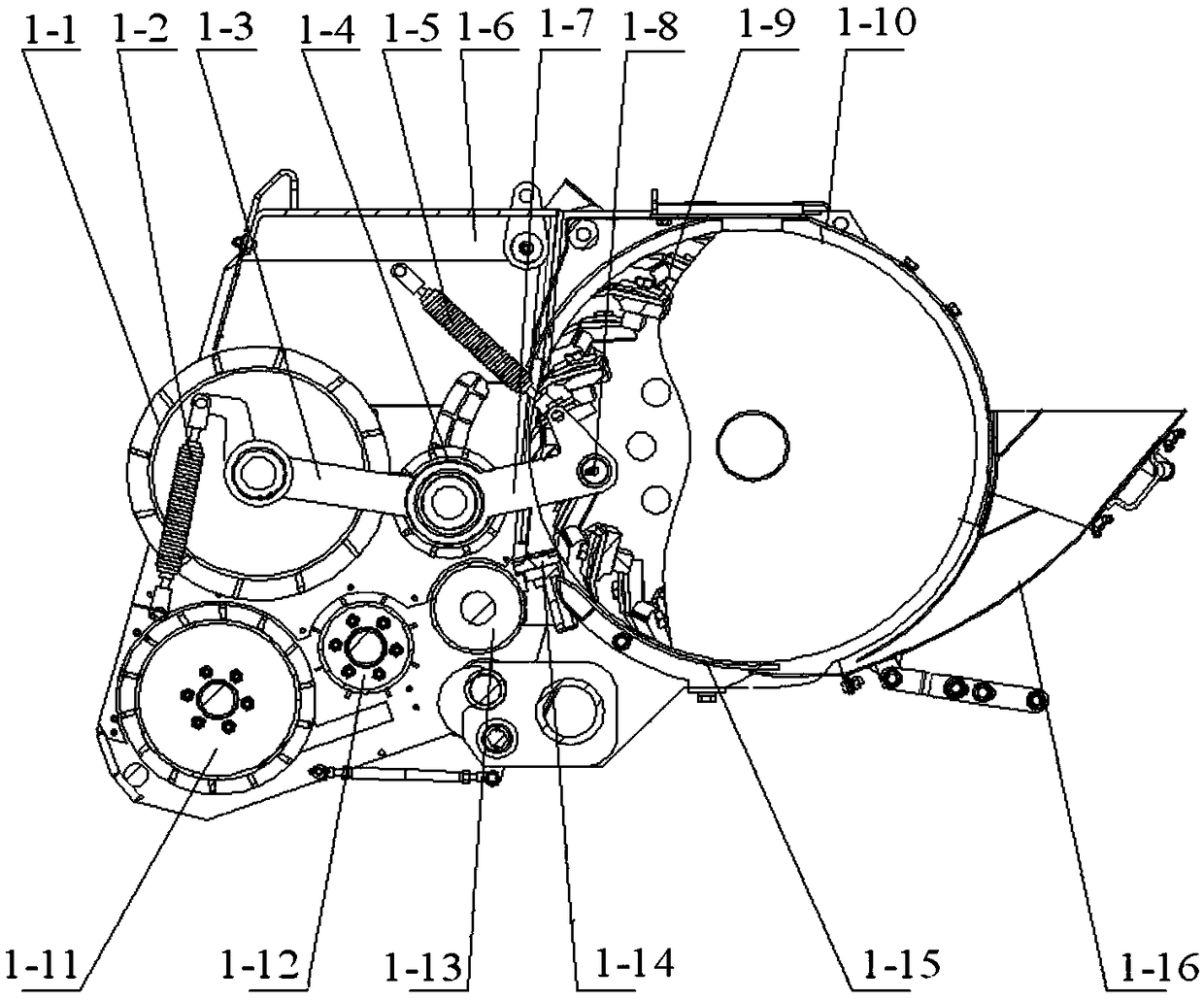

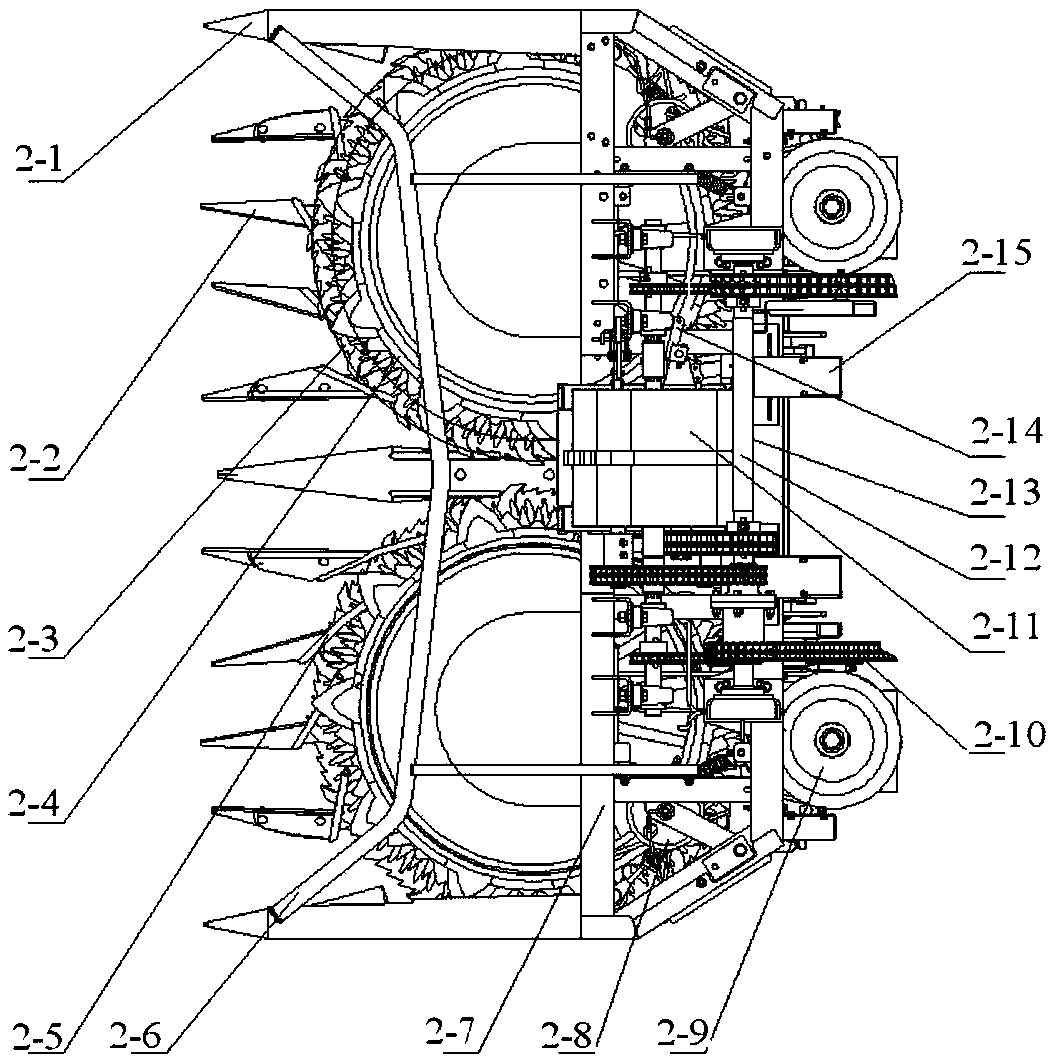

[0031] Below in conjunction with specific embodiment and description Figure 1~5 A kind of self-propelled green forage harvester of the present invention is described in detail.

[0032] The invention provides a small self-propelled green forage harvester, which includes a feeding device assembly 1, a header 2, a chopping device assembly 3, a transition cylinder assembly 4, a grain breaker assembly 5, a power system 6, and a walking system 7. Frame 8, fuel tank 9, rear steering axle 10, grass collection box 11, hydraulic system 12, automatic sharpening device 13, cab 14, control platform assembly 15, auxiliary throwing device 16, throwing cylinder 17, etc. . Each working part adopts modular design, and adopts quick coupling structure between parts, which is very convenient for assembly, maintenance, repair and adjustment. Simultaneously, the cutting platform 2 can be replaced with a picking-up cutting platform or a mowing cutting platform, so that one machine with multiple f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com