Cascade utilization oriented removal method for decommissioned battery parallel module

A battery and parallel technology, applied in sorting and other directions, can solve the problems of heavy workload, inconsistent aging degree, and inability to judge the aging degree of battery cells, and achieve the effect of wide application and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

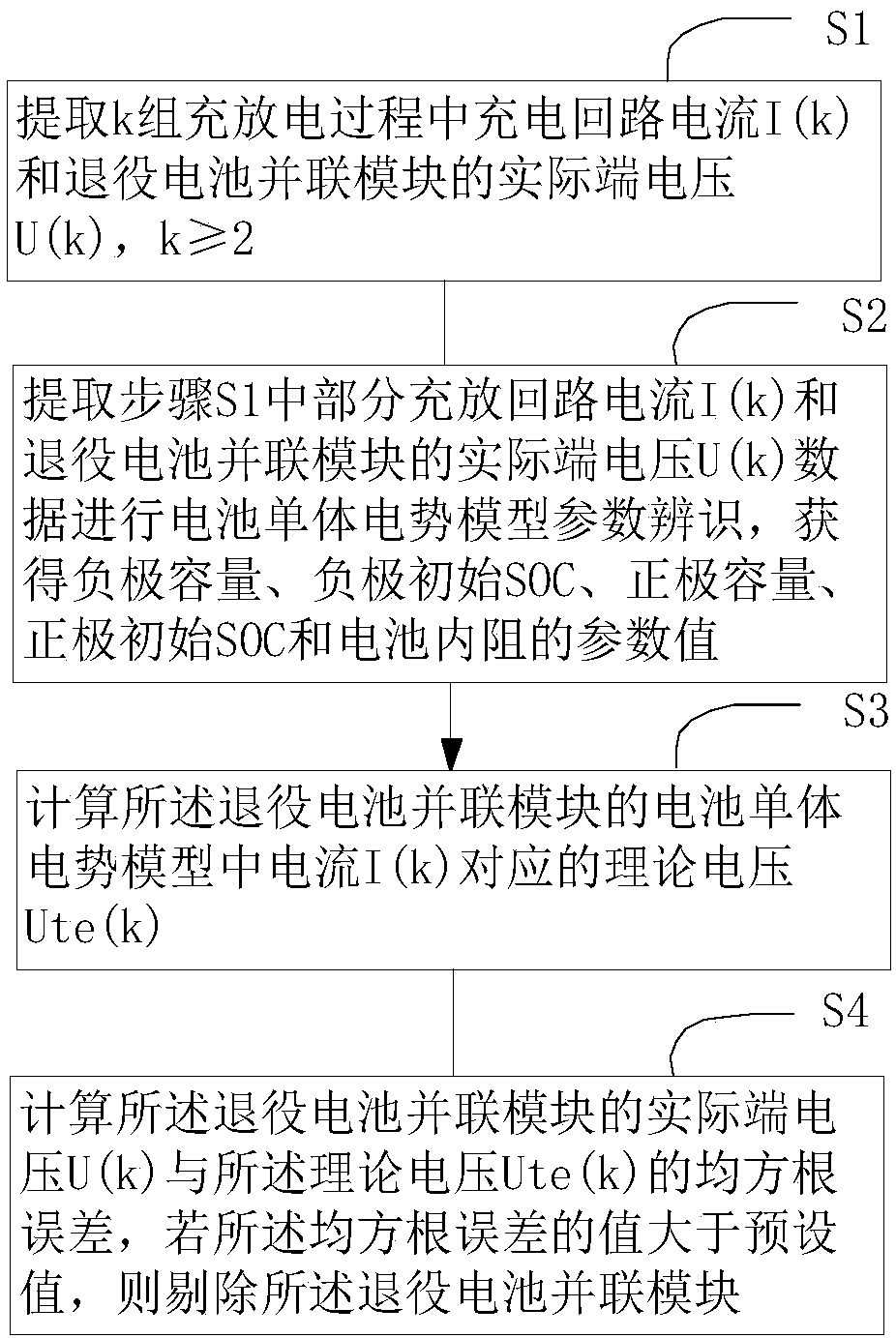

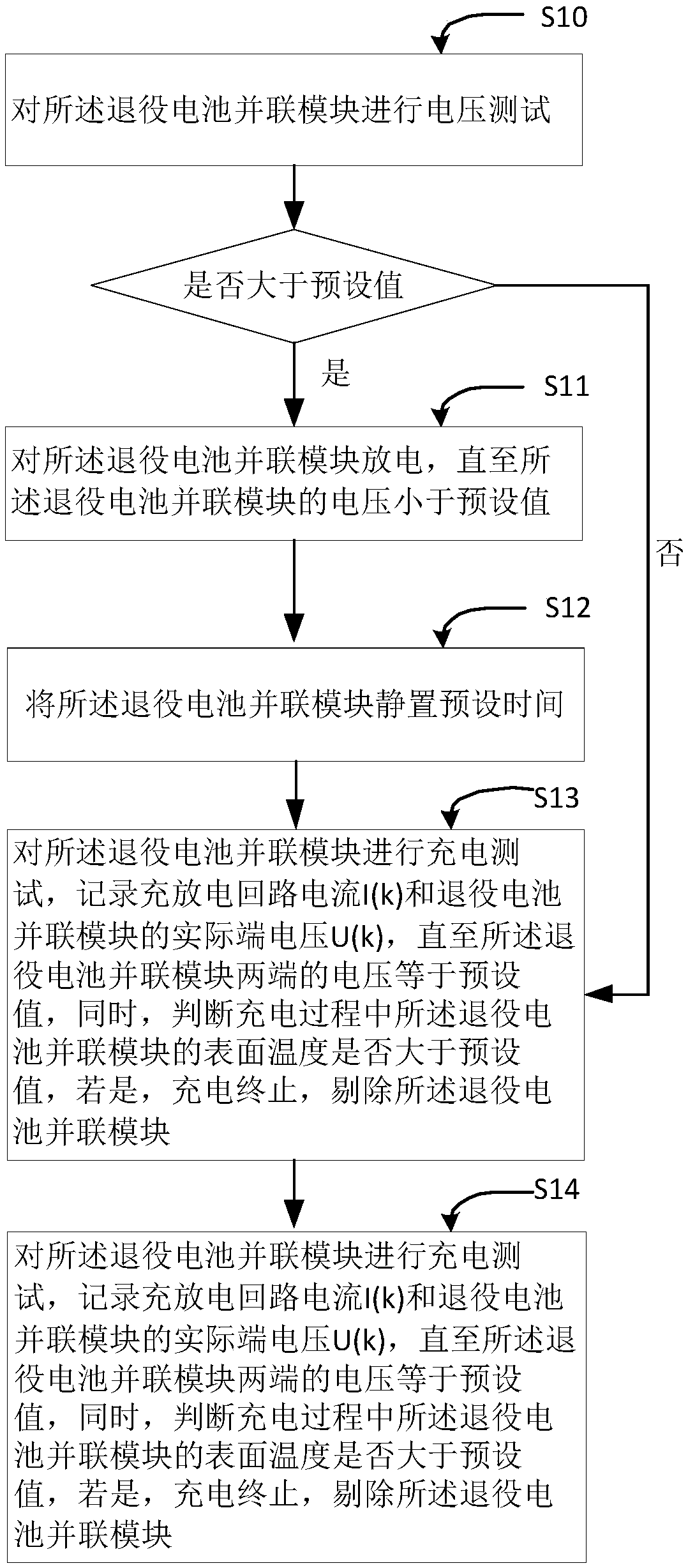

[0033] Such as figure 1 As shown, a method for removing decommissioned battery parallel modules for cascade utilization includes the following steps:

[0034] S1 extracts the charging circuit current I(k) and the actual terminal voltage U(k) of the decommissioned battery parallel module during the charging and discharging process of k groups, k≥2;

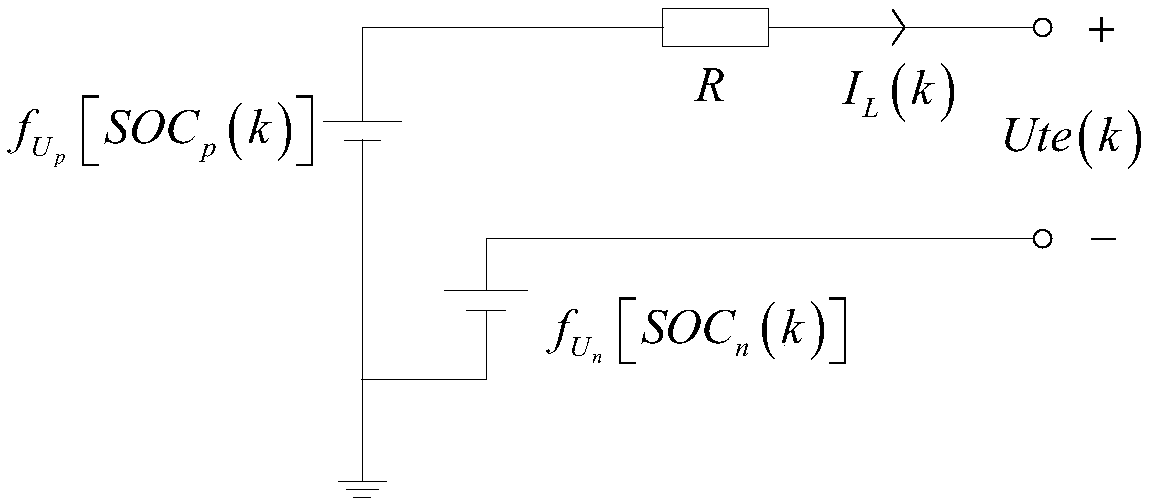

[0035] S2 Extract part of the charge-discharge circuit current I(k) in step S1 and the actual terminal voltage U(k) of the decommissioned battery parallel module to identify the parameters of the battery cell potential model, and obtain the negative electrode capacity, negative electrode initial SOC, positive electrode capacity, and positive electrode initial state. Parameter values of SOC and battery internal resistance;

[0036] The method of parameter id...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com