Operating method for processing wastewater containing nano nickel oxide through anaerobic ammonia oxidation technology

A technology of anaerobic ammonium oxidation and nano-nickel oxide, applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc., to achieve the effect of strengthening the ability of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

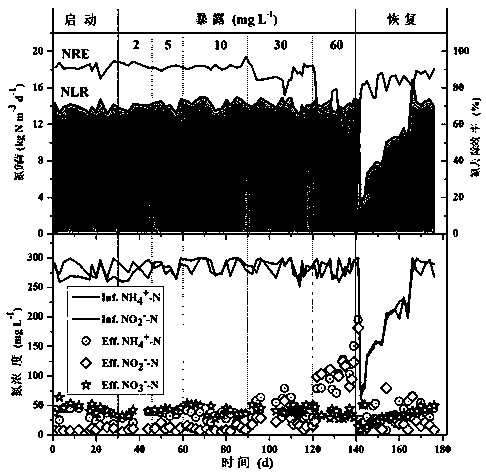

Embodiment 1

[0023] In continuous flow, an upflow anaerobic sludge bed (UASB) reactor with an effective volume of 1 L (e.g. figure 1 ), with an activity of 245 g TN·g -1 VSS·d -1 The anaerobic ammonium oxidation granular sludge is inoculated sludge, which simulates the influent NH of wastewater 4 + -N and NO 2 - -N is added at a ratio of 1:1, and the inorganic salt buffer and trace element I and trace element II to maintain the growth of microorganisms are added to adjust the operation of the reactor. o C. Operate under the condition that the influent pH is 7.80±0.19 and the hydraulic retention time is 0.96 h. The composition of the final concentration of the inorganic salt buffer solution in the simulated wastewater in the influent: KH 2 PO 4 10 mg·L -1 , CaCl 2 2H 2 O 5.6 mg L -1 , MgSO 4 ·7H 2 O 300 mg·L -1 , KHCO 3 1250 mg·L -1 , the solvent is deionized water; each 1.25 mL of trace element I and trace element II is added to 1 L of influent water, trace element I: EDT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com