A method for making bumps on the surface of the lower electrode by dry etching

A technology of electrode surface and fabrication method, applied in instrument, coating, optics, etc., can solve the problems of poor uniformity, difficult selection of masking material, expensive plasma spraying machine, etc., so as to reduce Mura defects and improve etching. Yield rate, the effect of shortening the production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following describes the specific implementation of the present invention in further detail through the description of the embodiments with reference to the accompanying drawings. The purpose is to help those skilled in the art have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and Contribute to its implementation.

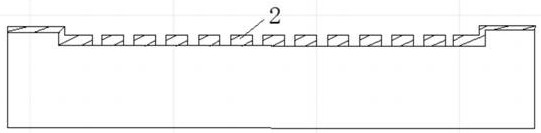

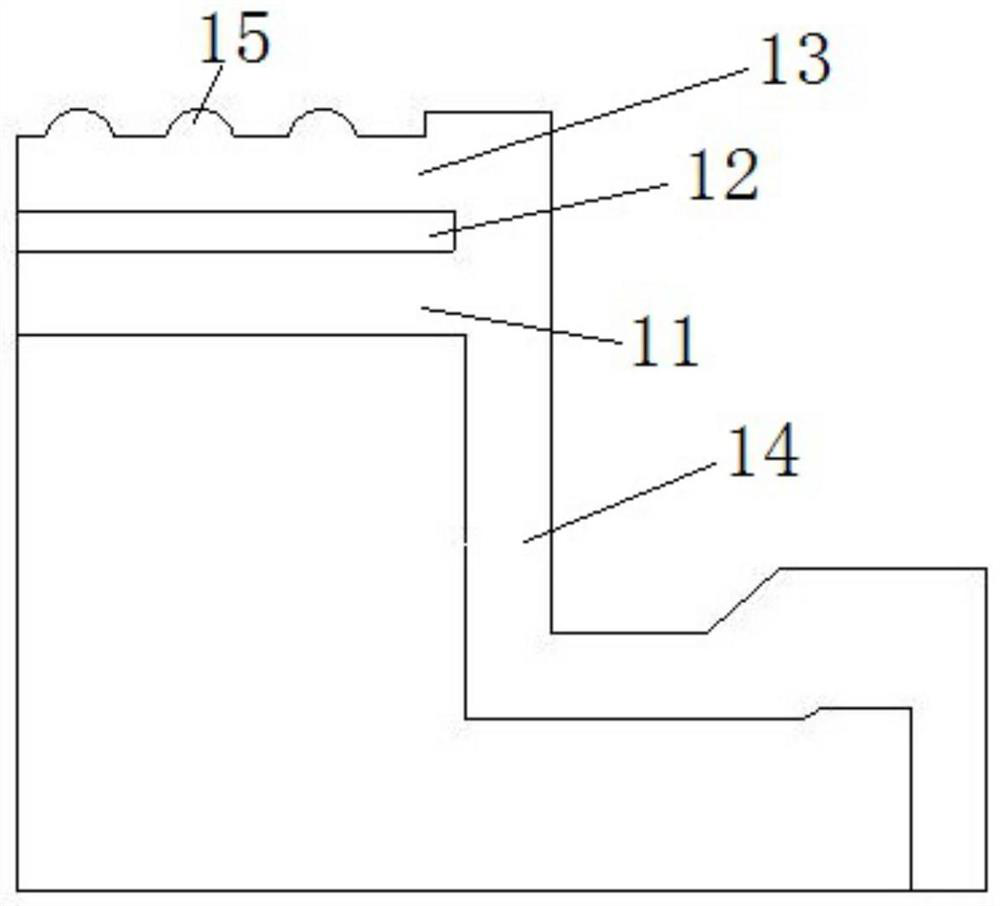

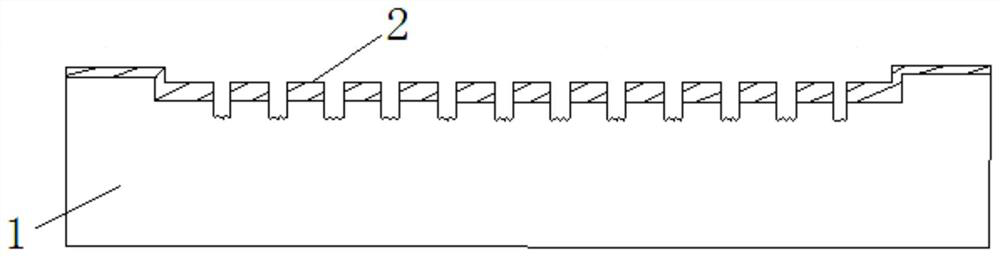

[0030] Such as Figure 1 to Figure 4 As shown, the lower electrode 1 has a sandwich structure. On the upper part of the stainless steel or aluminum base, from bottom to top, there are a first insulating layer 11, a conductive layer 12, and a second insulating layer 13; in addition, there are planes extending from the lower end of the substrate. To the conductive layer DCport (DC power supply terminal), applying a direct current to the DC port will induce a negative charge under the glass. The positive charge of the tungsten layer (conductive layer) and the negative charge under the glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com