A first-stage transition step aerated structure and energy dissipation method with variable elevation angle and plane angle

A technology of changing elevation and plane angle, applied in marine engineering, construction, barrage/weir, etc., can solve problems such as cavitation and cavitation damage of stepped spillway, and achieve the improvement of atomization phenomenon, significant energy dissipation effect, and change The effect of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

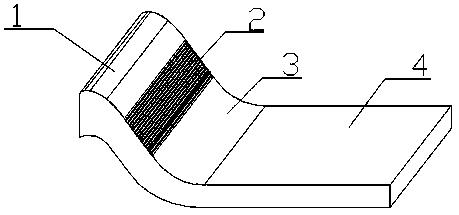

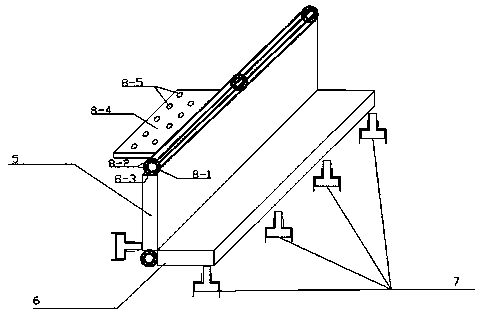

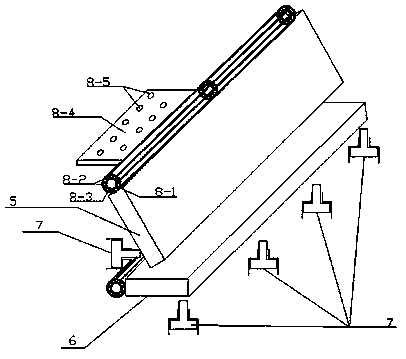

[0044] Embodiment 1: as Figure 1~12 As shown, a first-stage transitional aerated structure with variable elevation angle and plane angle, including WES curve section 1, WES straight section 2, WES anti-arc section 3, stilling pool 4, first-stage transition staircase elevation 5, First stage transition ladder plane 6, auxiliary hydraulic jacking device, main hydraulic jacking device, rotating shaft part 8, pressure sensor, controller, WES curve section 1 is connected with WES straight section 2, WES straight section 2 is connected with WES reverse arc section 3 Connection, the tail of the WES anti-arc section 3 is connected to the stilling pool 4, the front 4 of the stilling pool is connected to the first transitional ladder facade 5, the first transitional ladder facade 5 is located above the first transitional ladder plane 6, and the first transition The bottom of the lower end of the ladder facade 5 and the bottom of the rear end of the first transition step plane 6 are ins...

Embodiment 2

[0054] Embodiment 2: As shown in Fig. 4, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the relative angle ο of the first transition step elevation 5 does not change, only for the first transition step plane 6 The relative angle Ѳ is adjusted, by adjusting the auxiliary hydraulic jacking device at the rear end of the transition step plane 6 of the first step, and through the auxiliary work of the rotating shaft 8 at the front end of the transition step plane 6 of the first step, so as to achieve the adjustment of the transition step plane 6 of the first step The change of the relative angle Ѳ. In this way, the concentration of air entrainment in the process of flood discharge and energy dissipation can be increased, and the degree of cavitation erosion suffered by the stepped surface can be reduced.

Embodiment 3

[0055] Embodiment 3: as image 3 As shown, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the relative angle Ѳ of the transitional step plane 6 of the first step is not changed, and only the relative angle Ѳ of the transitional step elevation 5 of the first step is adjusted. Adjust the auxiliary hydraulic jacking device at the lower end of the transitional stepped facade 5 of the first stage, and perform auxiliary work through the rotating shaft 8 at the upper end of the transitional stepped facade 5 of the first stage, so as to achieve the relative angle ο of the transitional stepped facade 5 of the first stage. Change. In this way, the concentration of air entrainment in the process of flood discharge and energy dissipation can be increased, and the degree of cavitation erosion suffered by the stepped surface can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com