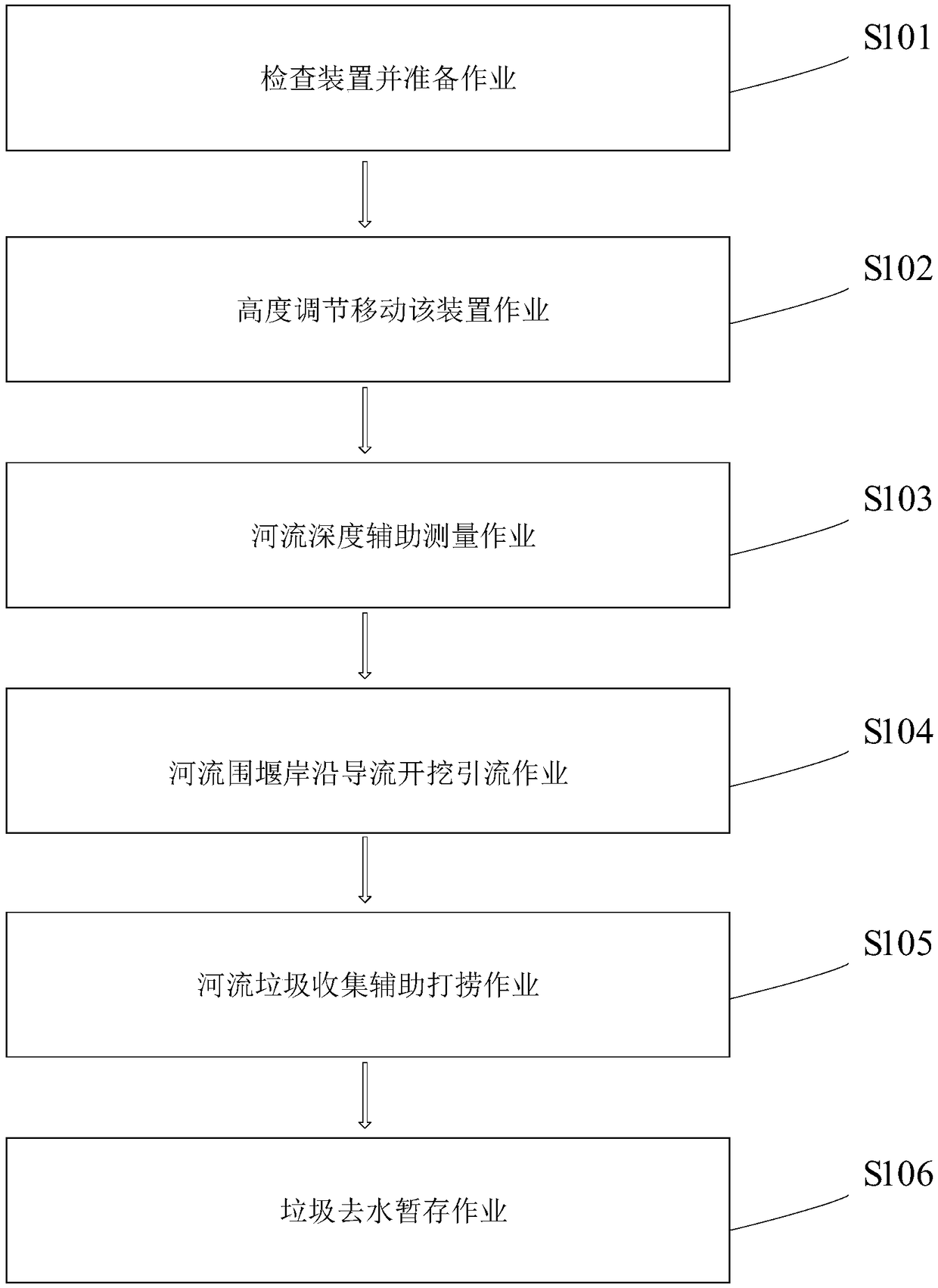

Construction device for river cofferdam diversion and application method thereof

A technology for construction devices and rivers, applied in water conservancy engineering, marine engineering, infrastructure engineering and other directions, can solve the problems of low construction efficiency, river cofferdam ditching, complicated operation steps, etc., so as to reduce the operation intensity and facilitate the excavation work. , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

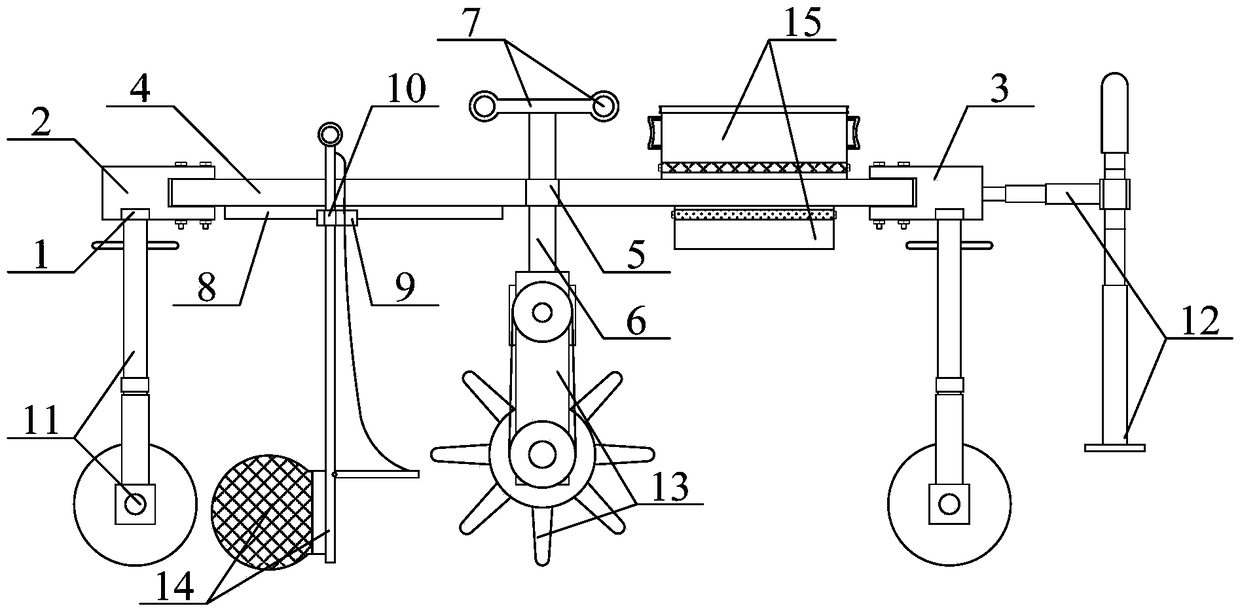

[0059] The present invention will be further described below in conjunction with accompanying drawing:

[0060] In the picture:

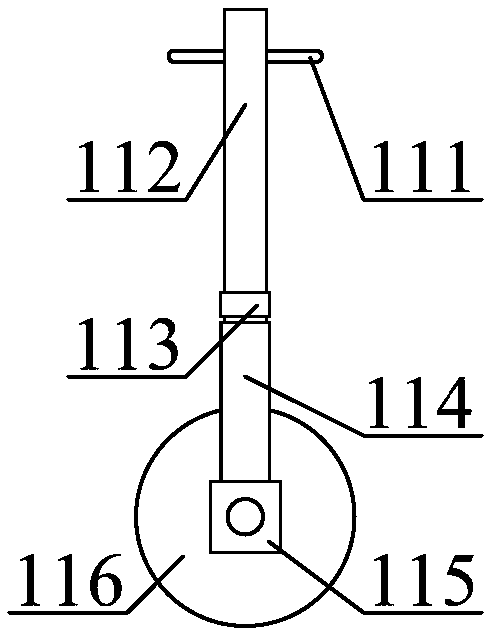

[0061] as attached figure 2 to attach Figure 7 shown

[0062] A construction device for river cofferdam flow diversion, including a conventional bearing 1, a main concave connecting seat 2, an auxiliary concave connecting seat 3, a machine base 4, a fixing nut 5, an adjusting screw 6, a rotating handle 7, and a linear slide rail 8 , U-shaped slider 9, fixed casing 10, height-adjustable quick-displacement wheel structure 11, river depth auxiliary measurement telescopic rod structure 12, river cofferdam bank along the diversion excavation diversion wheel structure 13, river garbage collection auxiliary salvage pocket Structure 14 and garbage dewatering temporary storage box structure 15, the middle position of the inner lower left side of the main concave type connecting seat 2 is inlaid with a conventional bearing 1; the middle position of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com