Open caisson construction method for stereo garage

A technology of three-dimensional garage and construction method, which is applied to caissons, artificial islands, water conservancy projects, etc., can solve the problems of long construction period of underground three-dimensional garage, achieve good waterproof effect, high assembly efficiency, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

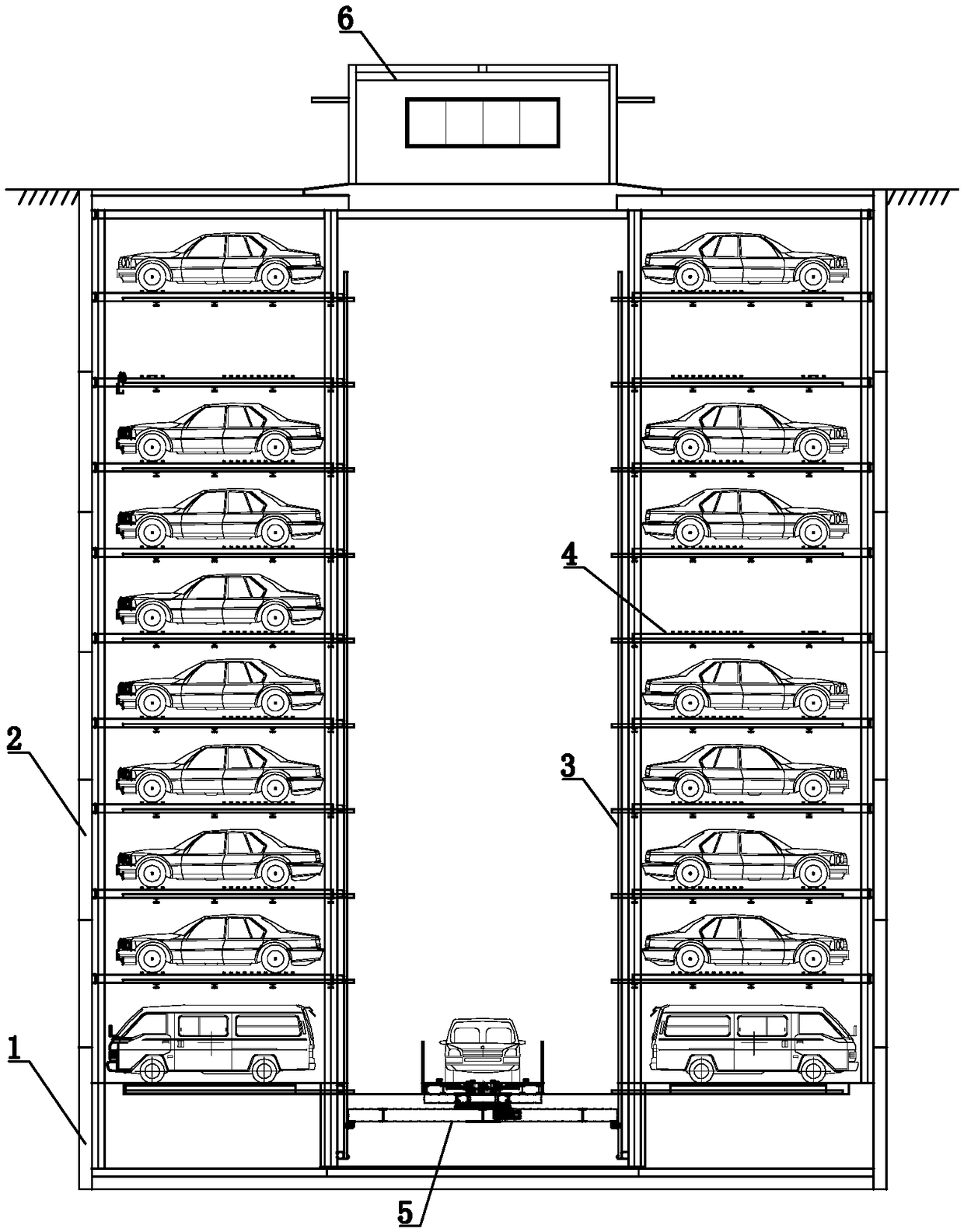

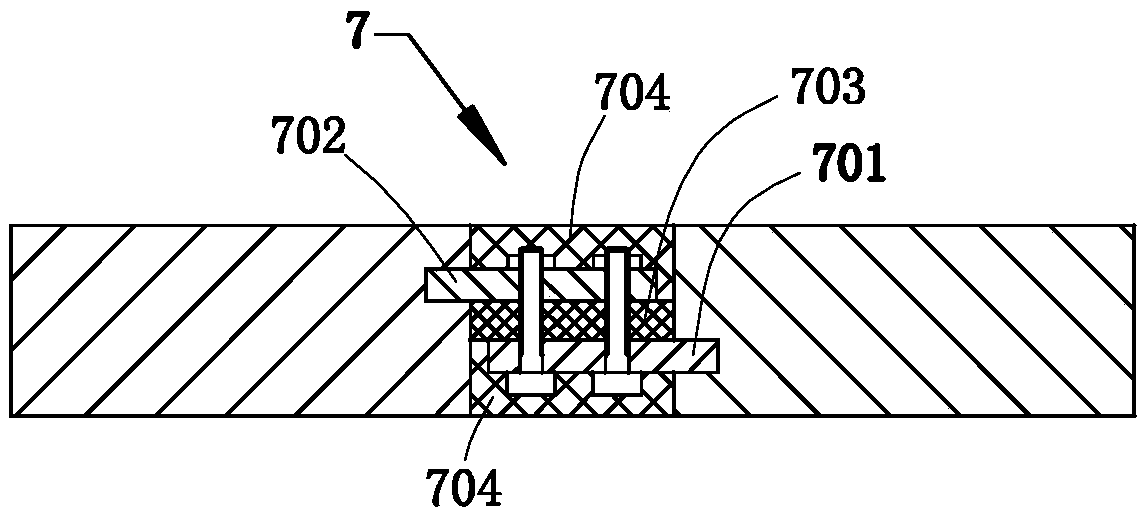

[0030] The present invention provides a kind of caisson construction method of three-dimensional garage, comprises the following steps: S1, the body of wall of underground garage is divided into upper and lower several layers along height, as figure 1 As shown, the bottom layer is the blade foot layer, and the rest are standard layers. The blade foot layer is divided into several blade foot prefabricated walls 1 along the circumference, and the standard layer is divided into several standard prefabricated walls 2 along the circumference. A first connection mechanism 7 is provided between two blade foot prefabricated walls 1, and a first connection mechanism 7 is also provided between two circumferentially adjacent standard prefabricated walls 2, such as figure 2 As shown, the first connecting mechanism 7 includes a first rigid connecting body 701 and a second rigid connecting body 702, the first rigid connecting body 701 and the second rigid connecting body 702 can be steel plat...

Embodiment 2

[0036] The present invention provides a caisson construction method for a three-dimensional garage, the process steps of which are basically the same as those in Embodiment 1, the difference being that:

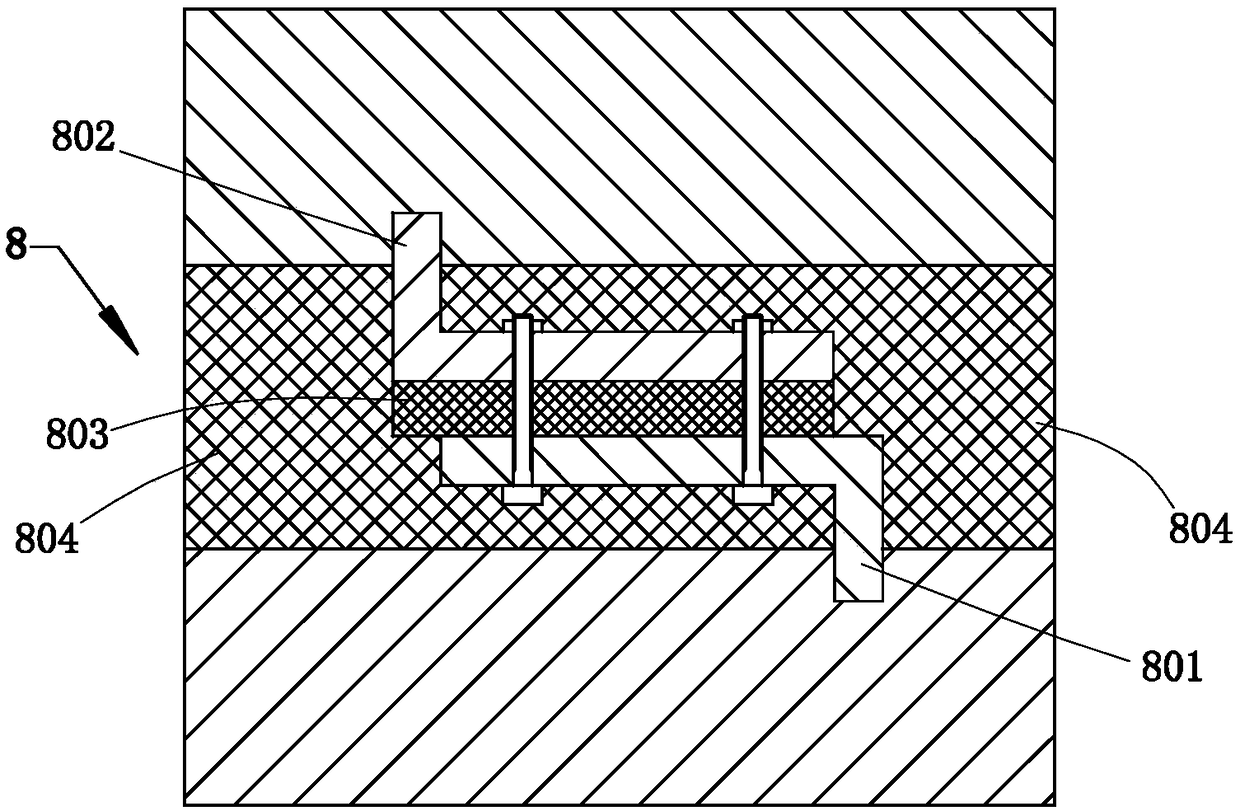

[0037] like Figure 4 As shown, the first connecting mechanism 7 includes a first rigid connecting body 701 and a second rigid connecting body 702, the first rigid connecting body 701 and the second rigid connecting body 702 can be steel plates or section steel, and the first rigid connecting body 701 is prefabricated in On the left side of the corresponding edge-foot prefabricated wall 1 or standard prefabricated wall 2, the second rigid connector 702 is prefabricated on the right side of another adjacent edge-foot prefabricated wall 1 or another standard prefabricated wall 2 , the first rigid connecting body 701 and the second rigid connecting body 702 are connected by fasteners, the fasteners are arranged horizontally up and down, and a first waterproof rubber plate 703 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com