Air condition compressor discharge valve plate limiter

A technology of air-conditioning compressors and exhaust valves, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of heavy metal valves, low gas transmission coefficient, and low pressure coefficient, and achieve Reasonable structure, reduced contact area, and low impact speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make those skilled in the art better understand the technical scheme of the present invention, the present invention will be further described below in conjunction with embodiment:

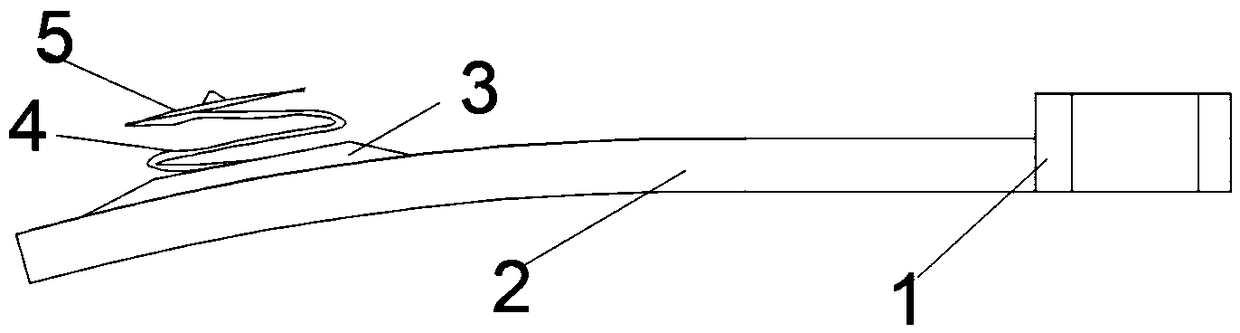

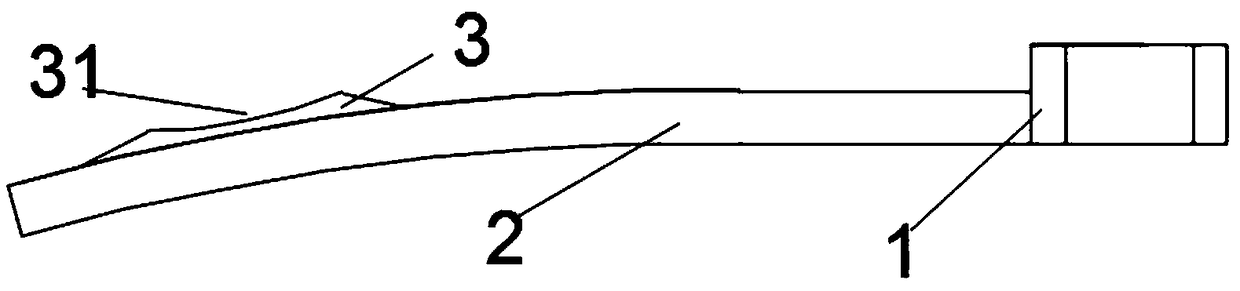

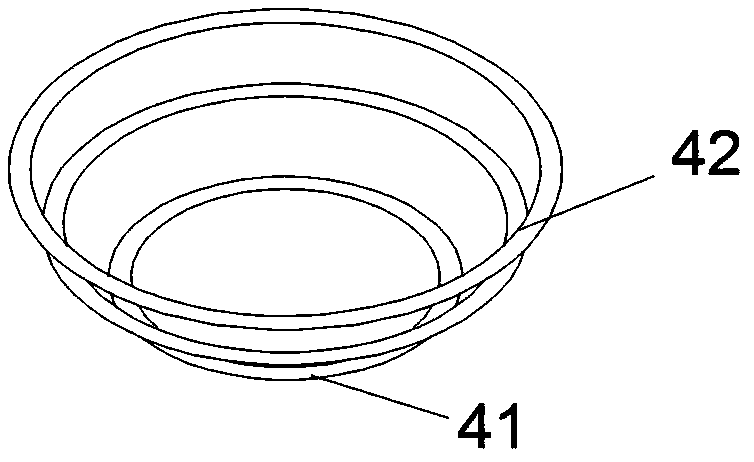

[0017] An air-conditioning compressor exhaust valve plate stopper includes a fixed part 1 and a curved part 2, one end of the fixed part 1 is fixedly connected to one end of the curved part 2, the fixed part 1 is a planar plate structure, and the The curved part 2 is an arc-shaped plate structure, and the other end of the curved part 2 is provided with a bump 3 on the upper surface, and an elastic buffer 4 is connected to the upper surface of the bump 3. The elastic buffer 4 The top is connected with a carbon fiber ring member 5 .

[0018] Preferably, the thickness of the curved part 2 is half of the thickness of the fixed part 1 , and the thickness of the protrusion 3 is half of the thickness of the curved part 2 .

[0019] Preferably, the elastic buffer 4 is a telescopic tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com