Non-stirring automatic brewing method

An automatic brewing and stirring technology, applied in beverage preparation devices, kitchen utensils, home utensils, etc., can solve problems such as affecting the convenience and ease of use, producing peculiar smell, breeding bacteria, etc., saving labor costs and space occupation. Cost, high cup and stock volumes, effect of reduced maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

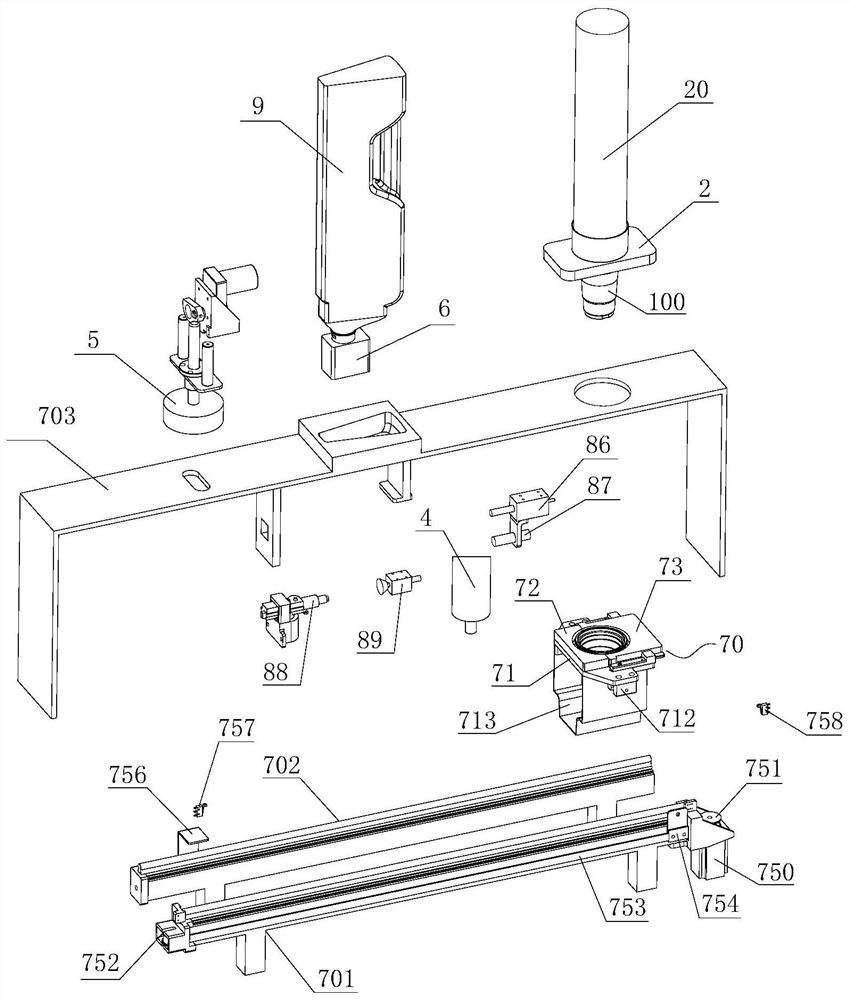

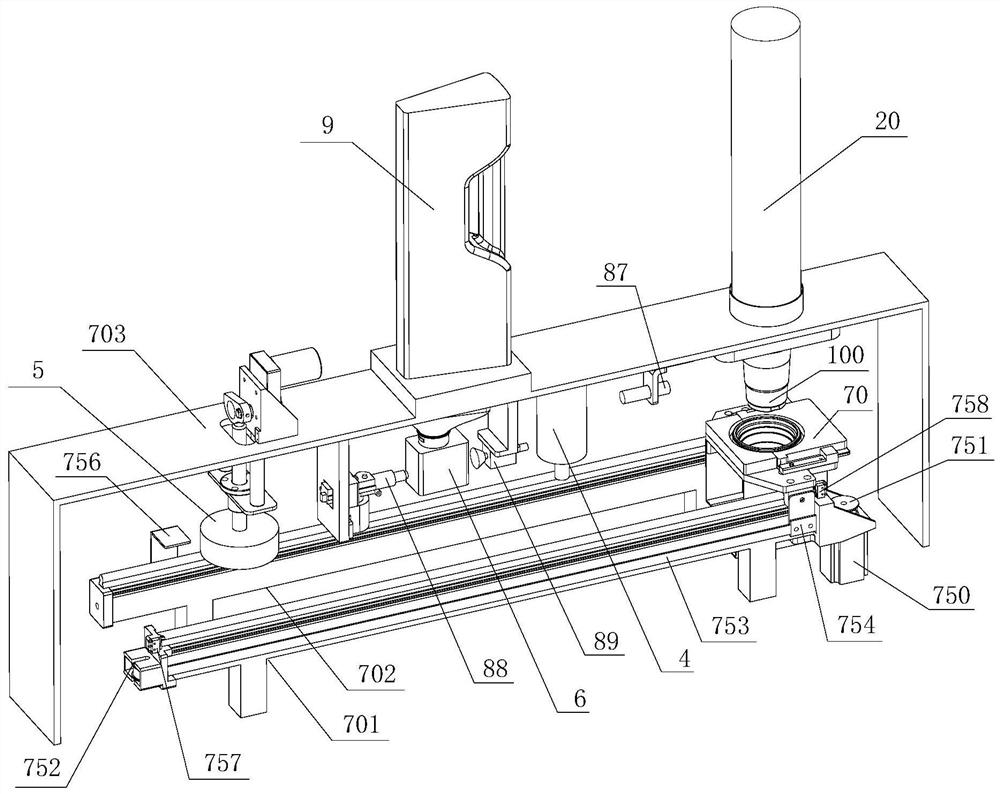

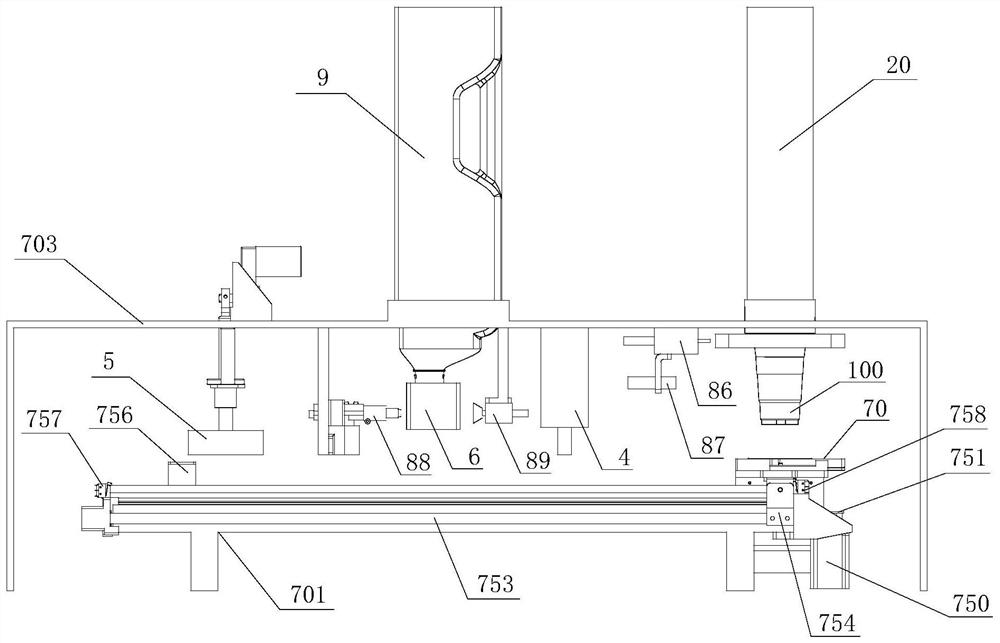

[0069] System Embodiment 1: A non-stirring automatic brewing and cup-discharging system provided in Embodiment 1. Its structural schematic exploded view is as follows figure 1 As shown, the structural schematic general assembly stereogram is shown in figure 2 As shown, the structural schematic general assembly front view is as follows image 3 As shown, it includes a cup-moving and cup-out mechanism, and the cup-moving and cup-out mechanism includes a frame provided with a slide rail, a displacement device 70 slidingly matched with the slide rail (that is, the displacement device slides along the slide rail), and a driving displacement device 70 The moving driving device; the cup dropping mechanism, the material dropping mechanism, the water supply mechanism 4 and the cup sealing mechanism 5 are arranged above the sliding track of the displacement device 70 . Such as Figure 4 The schematic exploded view of the structure when the given displacement device carries a cup, and...

Embodiment 2

[0088] System Embodiment 2: The structure is basically the same as that of System Embodiment 1, and the similarities will not be repeated here. The difference is:

[0089] Compared with the cup dropping mechanism, the water supply mechanism 4, the blanking mechanism and the cup sealing mechanism 5 in Embodiment 1, which are relatively linearly arranged above the sliding track of the displacement device, the cup dropping mechanism and the blanking mechanism in Embodiment 2, or the dropping mechanism The cup mechanism, the material blanking mechanism and the water supply mechanism are installed on the rotating device. The rotating device above the sliding track. In some embodiments, more than one cup dropping mechanism and more than one material dropping mechanism are installed on the rotating device. The first processing position mentioned in the article is located above the sliding track of the displacement device in the cup-moving and cup-out mechanism, which is the preset c...

Embodiment 3

[0109] The embodiment of this method provides a non-stirring type automatic brewing and cupping method, the cup brewing and cupping system used in it includes a processor, and a cup dropping mechanism, a material dropping mechanism, a water supply mechanism, and a cup sealing mechanism connected to the processor and a cup-moving and cup-discharging mechanism, the cup-moving and cup-discharging mechanism includes a displacement device capable of carrying the cup to move along a sliding track, and the method includes the following steps:

[0110] 1) According to the received user input information, drop the cup to the displacement device located below the cup drop mechanism through the cup drop mechanism to make it accept the dropped cup (or drive the displacement device to move below the cup drop mechanism to accept the dropped cup from the cup drop mechanism cup);

[0111] 2) Drive the displacement device that has received the cup to move below the water supply mechanism, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com