A rare earth particle separation system

A particle separation and rare earth technology, which is applied in the field of rare earth particle separation systems, can solve the problems of low separation and recovery efficiency, difficult recovery of rare earth particles, and no centralized recovery of rare earth particles, and achieves the effect of improving recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

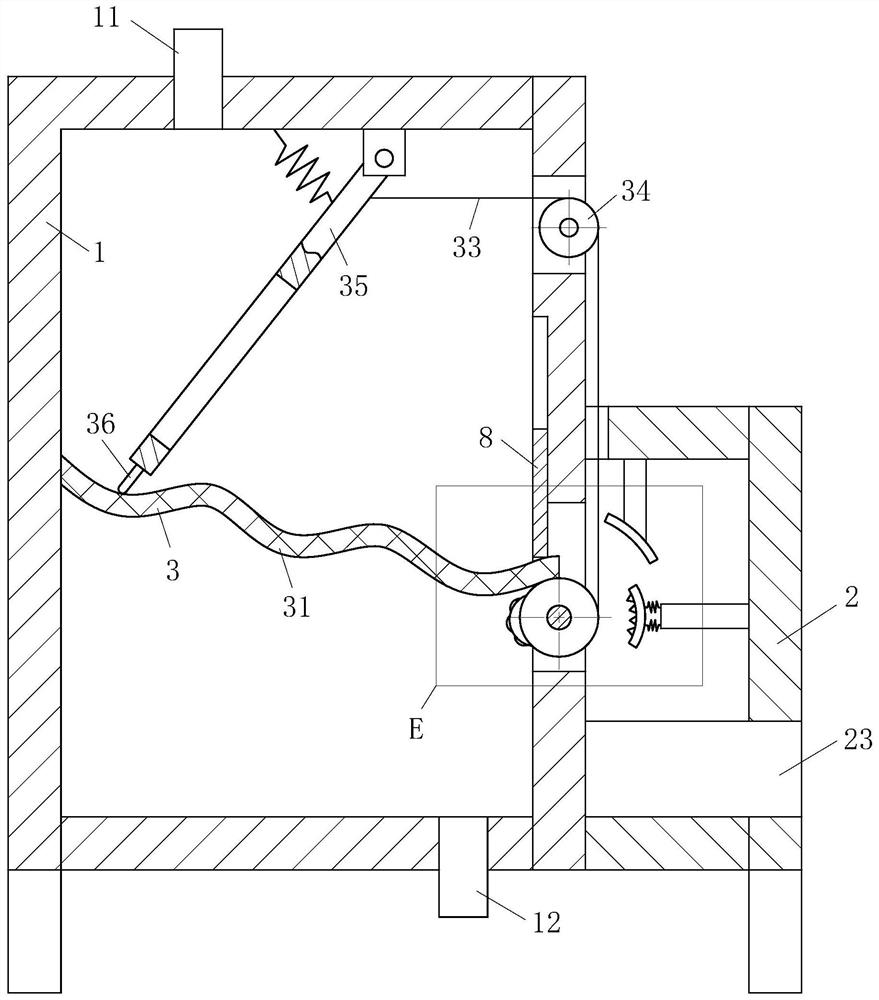

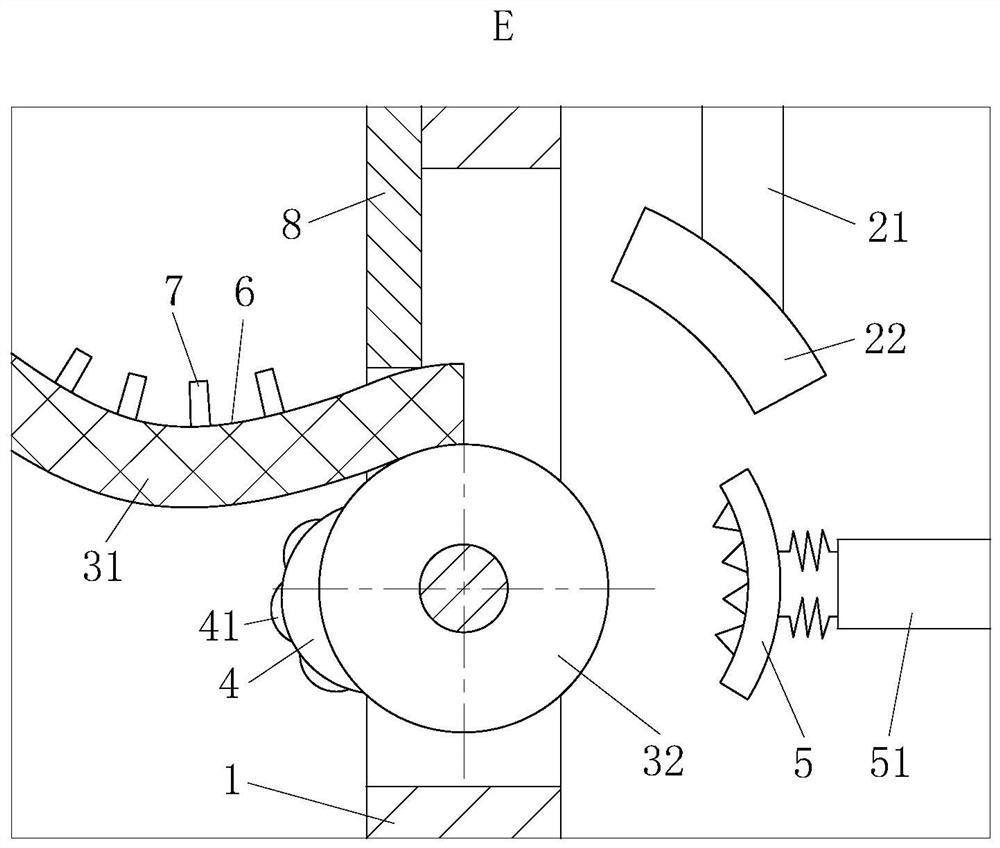

[0023] As an embodiment of the present invention, the outer ring of the rotating roller 32 is fixedly connected with the arc block 4 . When the rotating roller 32 rotates, the arc-shaped block 4 makes the trough of the elastic screen 31 fully arched, so that the rare earth particles in the trough of the elastic screen 31 are easy to fall, thereby improving the separation and recovery efficiency of the rare earth particles.

[0024]As an embodiment of the present invention, a group of airbags 41 are arranged on the outer arc surface of the arc block 4, and a group of air blowing holes are arranged on the surface of the airbags 41. Air outlet one-way valve, and an inlet one-way valve is installed on the air supply pipe. When the arc-shaped block 4 squeezes the elastic screen 31, the air bag 41 generates an airflow, blows air through the mesh of the elastic screen 31, and blows the rare earth particles on the surface of the elastic screen 31 away, so that the rare earth particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com