MPCVD (microwave plasma chemical vapor deposition) synthesis equipment and control method

A technology of synthesis equipment and control center, applied in chemical instruments and methods, control/regulatory processes, chemical/physical/physical-chemical processes, etc., can solve problems such as affecting product quality, unfavorable plasma, and fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

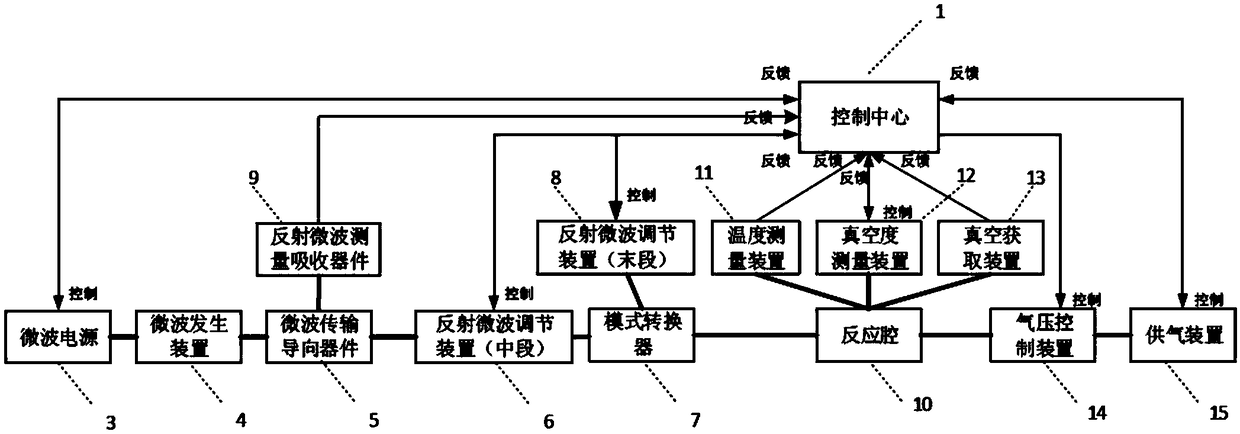

[0075] Such as figure 2 Shown, a kind of MPCVD synthesis equipment, comprises 1, control center; 3, microwave power supply; 4, microwave generator; 5; microwave transmission guiding device; 6, reflected microwave adjusting device (middle section); 1. Reflected microwave adjusting device (end section); 9. Reflected microwave measuring and absorbing device; 10. Reaction chamber; 11. Temperature measuring device; 12. Vacuum degree measuring device; 13. Vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com