Water-expansion molding process of a muffler for automobiles

A molding process and muffler technology, which is applied in the field of water swelling molding, can solve problems such as complicated trend, poor product appearance, and difficulty in ensuring precision, and achieve the effects of reducing manufacturing costs, improving appearance quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

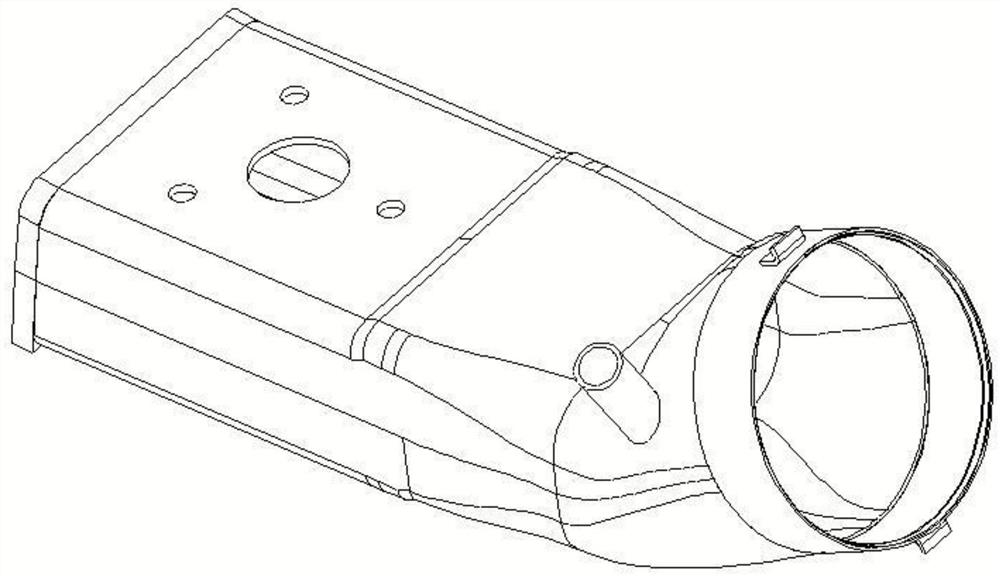

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] The present invention comprises following processing steps:

[0022] (1) Cut off the stainless steel pipe and remove the burrs;

[0023] (2) Use a pipe bender to bend stainless steel pipe fittings according to the appearance of the product;

[0024] (3) Solid-melt the bent pipe fittings, and then shape the two ends of the pipe fittings with plugs to keep the outer circle shape of the two ends unchanged, and then use the cold pressing mold to flatten the middle part at one time with a hydraulic press, and the hydraulic press Applied pressure greater than 315 tons;

[0025] (4) After solid-melting the product again, put the billet into the water-expanding mold, and use the water-expanding machine to apply pressure to the mold. Two pressurized cylinders at both ends of the mold push the punch to extrude the pipe fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com