A thin-walled conical energy absorbing box imitating a yak horn structure

A technology of yak horns and energy-absorbing boxes, which is applied to bumpers and other directions to achieve the effects of improving bearing capacity, improving energy-absorbing characteristics, and good step-by-step energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

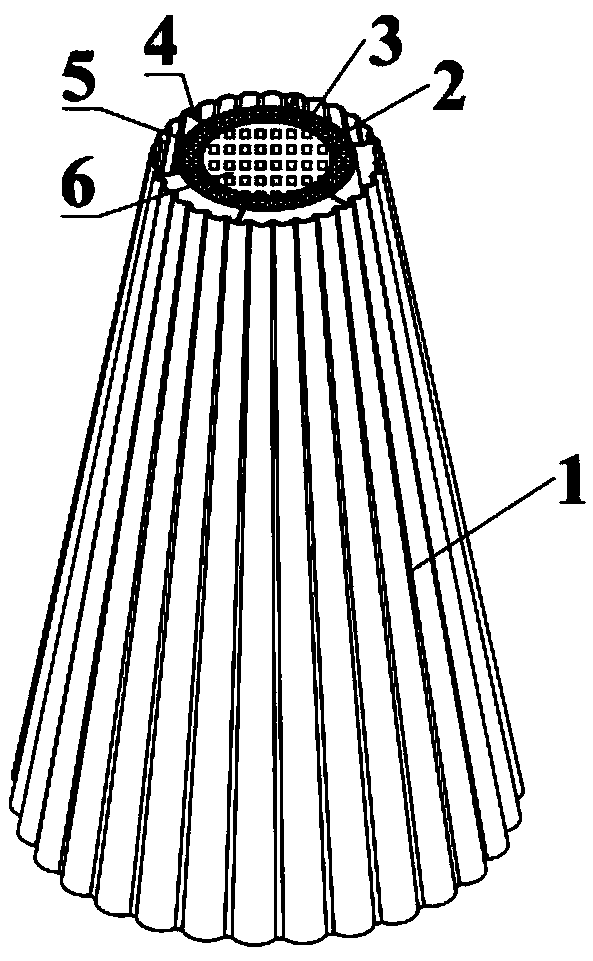

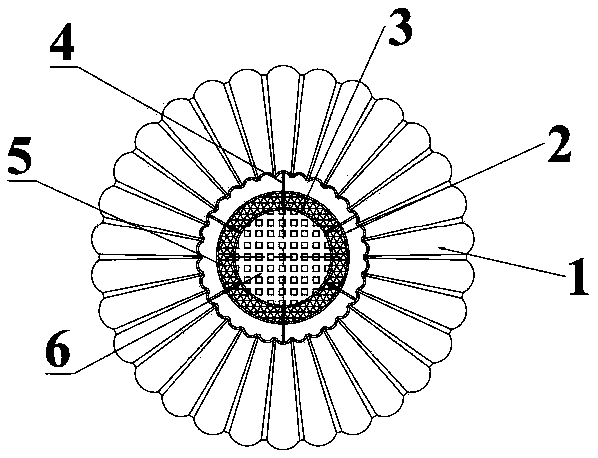

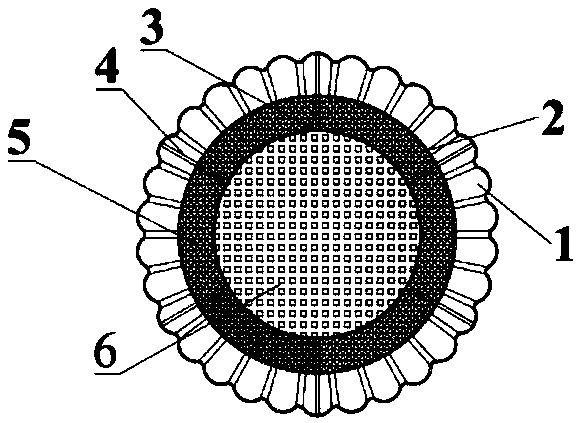

[0027] see Figure 1 to Figure 8 As shown, a thin-walled conical energy-absorbing box imitating a yak horn structure is composed of a bionic ribbed tube 1, a bionic inner tube 2, an inner and outer foamed aluminum layered tube 3, an outer layer of foamed aluminum 5, and an inner layer of foamed aluminum 6 Composed of connecting rib 4. The bionic ribbed tube 1 is designed based on the strip-shaped protrusions on the surface of the yak horn shell along the length direction, and the cross-sectional size gradually increases from top to bottom, which has a good step-by-step energy dissipation effect. The bionic inner tube 2, the outer layer of aluminum foam 5, the inner layer of aluminum foam 6 and the inner and outer layers of aluminum foam separating tube 3 are combined to form a bionic core body filled with foam aluminum, which is divided into high-density aluminum foam and low-density aluminum foam The two parts of foamed aluminum are designed to imitate the change of yak horn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com