Wastewater treatment device

A wastewater treatment, integrated technology, applied in multi-stage water treatment, water/sewage treatment, light water/sewage treatment, etc., can solve the problems of poor sewage treatment effect, affecting the service life of the device, difficult sewage purification treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

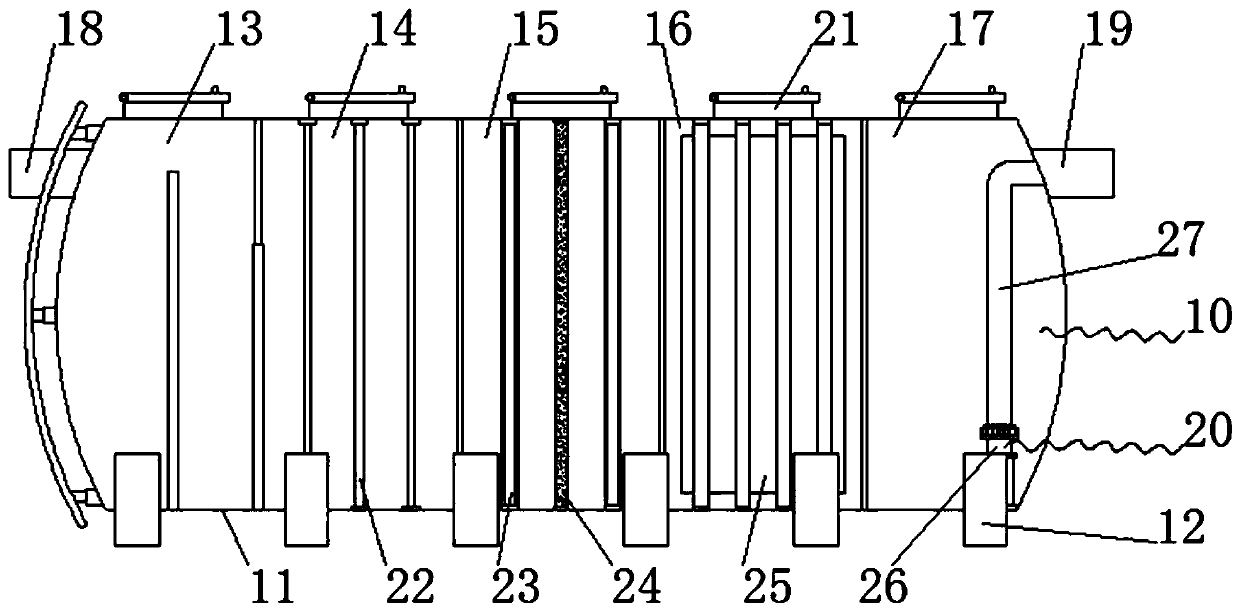

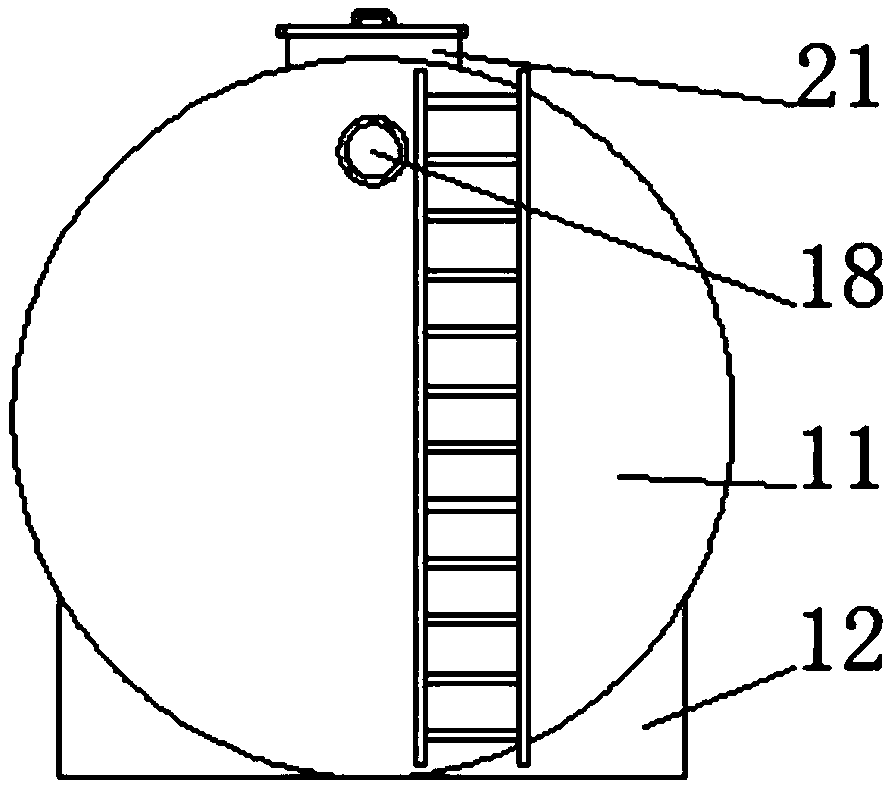

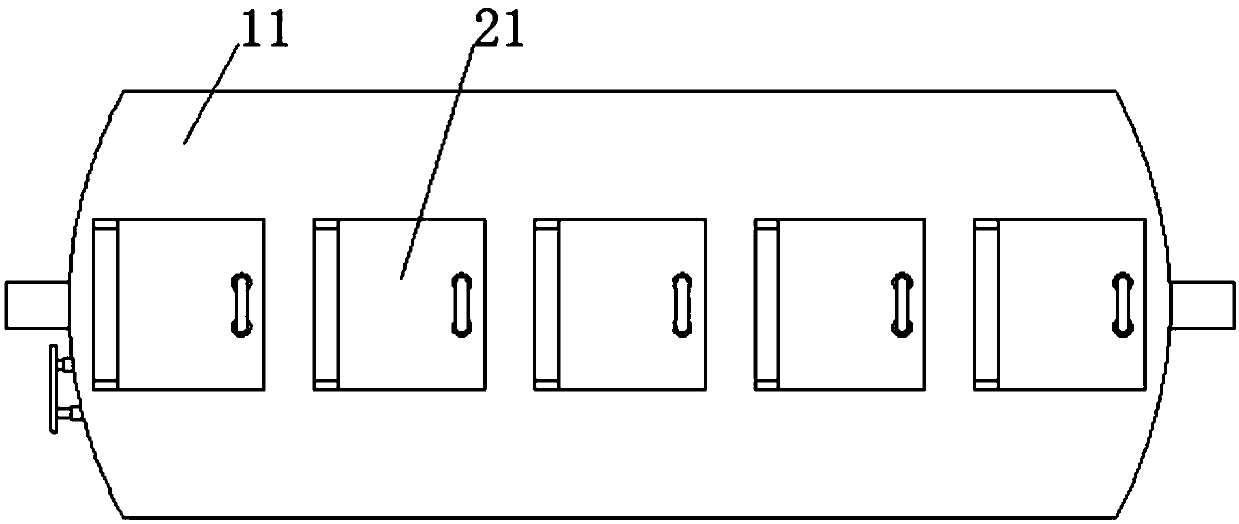

[0026] see Figure 1-3 , the present invention provides a technical solution: a wastewater treatment device, including a shell assembly 10, a functional assembly 20, the shell assembly 10 includes an integrated box 11, a base 12, a sedimentation box 13, a filter box 14, an electrolysis box 15, and a sterilization box 16 , clean water tank 17, water inlet pipe 18 and water outlet pipe 19, base 12 is provided below the outer side wall of the integrated case 11, the base 12 is fixedly connected with the integrated case 11, and the left side of the inner side wall of the integrated case 11 is provided with a sedimentation tank 13, and the sedimentation tank 13 is connected with the The integrated box 11 is fixedly connected, and the left side of the inner side wall of the integrated box 11 is close to the right side of the sedimentation box 13. There is a filter box 14, and the filter box 14 is fixedly connected with the integrated box 11. An electrolytic box 15 is arranged at the ...

Embodiment 2

[0041] The difference from Example 1 is that the surface of the shell assembly 10 is coated with a layer of anti-corrosion layer, and the preparation method of the anti-corrosion layer is:

[0042] Get the following components by weight for subsequent use: 20 parts of toluene cyclohexanone, 4 parts of talcum powder, 5 parts of heavy calcium carbonate, 12 parts of epoxy resin, 10 parts of tri-o-cresol phosphate, 3 parts of dammar resin, 7 parts of iron powder, 10 parts of pottery clay, 20 parts of deionized water.

[0043] S1. Prefabricated organic solvent: mix toluene cyclohexanone, epoxy resin, tri-o-cresol phosphate, and dammar resin, heat to 60°C, stir evenly, and keep warm for 4 hours;

[0044] S2. Preparation of anti-corrosion coating: add clay, iron powder, heavy calcium carbonate, talcum powder, and deionized water to the organic solvent in S1 in sequence, stir evenly, heat the temperature to 70° C., and keep it warm for 2 hours;

[0045] S3, processing: the anticorros...

Embodiment 3

[0050] The difference from Example 2 is that the formula of the anti-corrosion layer is modified and recoated on the shell assembly 10:

[0051] Get the following raw materials of each component by weight for subsequent use: 30 parts of toluene cyclohexanone, 6 parts of talcum powder, 8 parts of heavy calcium carbonate, 16 parts of epoxy resin, 12 parts of tri-o-cresol phosphate, 4 parts of dammar resin, 8 parts of iron powder, 15 parts of pottery clay, 24 parts of deionized water.

[0052] S1. Prefabricated organic solvent: mix toluene cyclohexanone, epoxy resin, tri-o-cresol phosphate, and dammar resin, heat to 60°C, stir evenly, and keep warm for 4 hours;

[0053] S2. Preparation of anti-corrosion coating: add clay, iron powder, heavy calcium carbonate, talcum powder, and deionized water to the organic solvent in S1 in sequence, stir evenly, heat the temperature to 70° C., and keep it warm for 2 hours;

[0054] S3, processing: the anticorrosion coating prepared in S2 is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com