Novel composite silica gel for flexible mobile phone shell

A mobile phone case and silica gel technology, which is applied in the field of new composite silica gel for flexible mobile phone cases, can solve the problems of equipment performance degradation, easy aging, and difficulty in heat dissipation, so as to improve aging resistance and service life, excellent heat resistance and low temperature resistance. The effect of performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

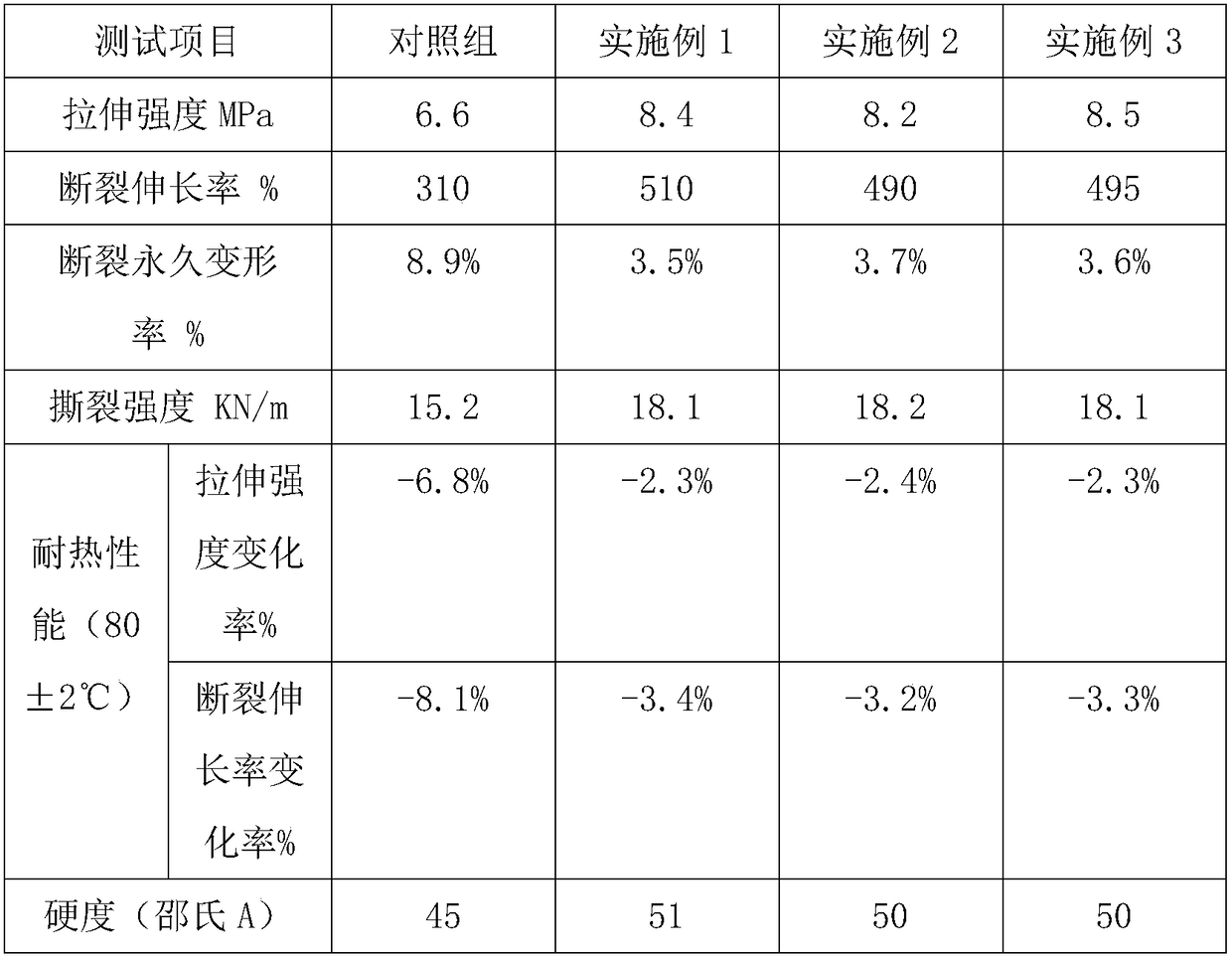

Embodiment 1

[0033]A new type of composite silica gel for flexible mobile phone cases. According to the parts by mass, the components of the composite silica gel include: 120 parts of silicone material, 55 parts of reinforced elastomer, 10 parts of carbon black, 7 parts of hydroxyl silicone oil, 3 parts of crosslinking agent, anti 2 parts of electrostatic auxiliary agent, 0.5 parts of platinum vulcanizing agent.

[0034] Wherein, the silica gel is a polyester-modified silica gel added with a monoamino-modified silicone block copolymer.

[0035] The crosslinking agent is DCP.

[0036] The antistatic additive is LiClO 4 .

[0037] The preparation method of the composite silica gel provided in this embodiment is:

[0038] According to the mass parts, add the silica gel material, reinforced elastomer and cross-linking agent into the vacuum kneader, knead in vacuum at a temperature of 150°C for 1.5h, then discharge the rubber material, cool naturally to room temperature, and then add it to t...

Embodiment 2

[0040] A new type of composite silica gel for flexible mobile phone cases. According to the parts by mass, the components of the composite silica gel include: 150 parts of silicone material, 65 parts of reinforced elastomer, 16 parts of carbon black, 13 parts of hydroxyl silicone oil, 6 parts of crosslinking agent, anti 4 parts of electrostatic additives, 1.2 parts of platinum vulcanizing agent.

[0041] Wherein, the silica gel is a polyester-modified silica gel added with a monoamino-modified silicone block copolymer.

[0042] The crosslinking agent is DBHP.

[0043] Antistatic additive is LiPF 6 .

[0044] The preparation method of the composite silica gel provided in this embodiment is:

[0045] According to the number of parts by mass, add silica gel material, reinforced elastomer and crosslinking agent into the vacuum kneader, knead in vacuum at a temperature of 155°C for 2 hours, then discharge the rubber material, naturally cool to room temperature, add it to the int...

Embodiment 3

[0047] A new type of composite silica gel for flexible mobile phone cases. According to the parts by mass, the components of the composite silica gel include: 140 parts of silicone material, 61 parts of reinforced elastomer, 13 parts of carbon black, 10 parts of hydroxyl silicone oil, 4.5 parts of crosslinking agent, anti-corrosion 3.2 parts of electrostatic auxiliary agent, 0.8 parts of platinum vulcanizing agent.

[0048] Wherein, the silica gel is a polyester-modified silica gel added with a monoamino-modified silicone block copolymer.

[0049] The crosslinking agent is DCP.

[0050] Antistatic additive is LiAsF 6 and LiBF 4 mixture.

[0051] The preparation method of the composite silica gel provided in this embodiment is:

[0052] According to the mass parts, add the silica gel material, reinforced elastomer and cross-linking agent into the vacuum kneader, knead in vacuum at a temperature of 152°C for 1.8h, then discharge the rubber material, cool naturally to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com