Low-temperature baking and drying high-salt-spray-resistant water-based electroplating gloss oil

A low-temperature baking, salt spray-resistant technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of polluting the environment, difficult to dry paint, difficult to adhere to its surface, etc., to achieve the effect of high strength and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

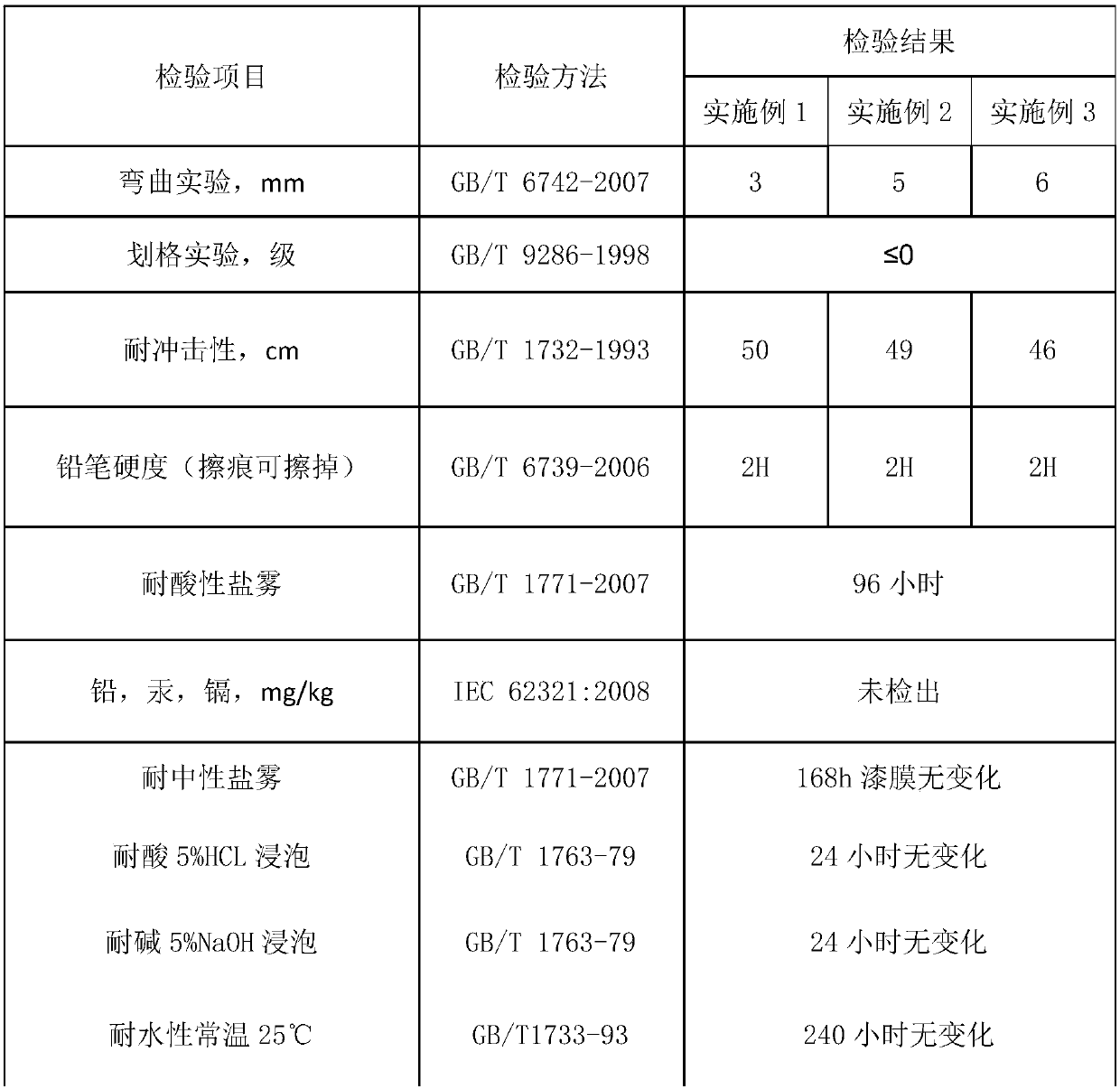

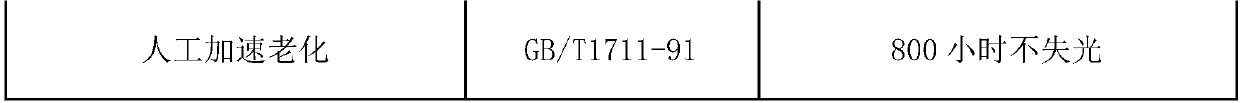

Embodiment 1

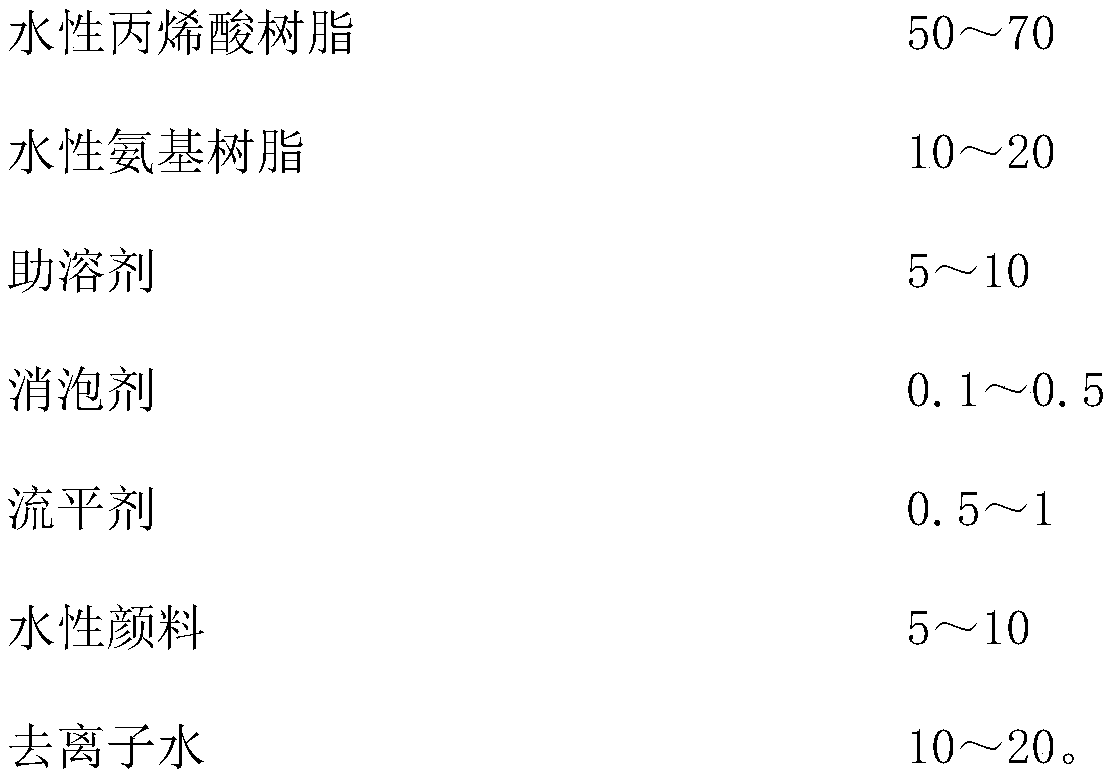

[0022] Components and proportioning (parts by weight) are as follows:

[0023] Water-based acrylic resin 65, water-based amino resin 15, co-solvent 8, defoamer 0.2, leveling agent 0.3, water-based pigment 5, deionized water 6.5.

[0024] Preparation steps:

[0025] a. Accurately weigh each component according to the formula;

[0026] b. Add water-based acrylic resin, water-based amino resin, co-solvent, defoamer and 50% deionized water in turn in A stirred tank, mix and stir evenly, and obtain A component;

[0027] c. Add leveling agent, water-based pigment and the remaining amount of deionized water into the B stirring tank, mix and stir evenly, and obtain B component;

[0028] d. Add component B into the stirring tank of A, stir and mix with component A evenly, use amine neutralizer to adjust the pH value of the mixture to 7.0-7.5, and prepare water-based electroplating varnish.

Embodiment 2

[0030] Water-based acrylic resin 60, water-based amino resin 15, co-solvent 8, defoamer 0.2, leveling agent 0.4, water-based pigment 6, deionized water 10.4.

[0031] Preparation steps:

[0032] a. Accurately weigh each component according to the formula;

[0033] b. Add water-based acrylic resin, water-based amino resin, co-solvent, defoamer and 50% deionized water in turn in A stirred tank, mix and stir evenly, and obtain A component;

[0034] c. Add leveling agent, water-based pigment and the remaining amount of deionized water into the B stirring tank, mix and stir evenly, and obtain B component;

[0035] d. Add component B into the stirring tank of A, stir and mix with component A evenly, use amine neutralizer to adjust the pH value of the mixture to 7.0-7.5, and prepare water-based electroplating varnish.

Embodiment 3

[0037] Water-based acrylic resin 56, water-based amino resin 10, co-solvent 8, defoamer 0.2, leveling agent 0.4, water-based pigment 6, deionized water 19.4.

[0038] Preparation steps:

[0039] a. Accurately weigh each component according to the formula;

[0040] b. Add water-based acrylic resin, water-based amino resin, co-solvent, defoamer and 50% deionized water in turn in A stirred tank, mix and stir evenly, and obtain A component;

[0041] c. Add leveling agent, water-based pigment and the remaining amount of deionized water into the B stirring tank, mix and stir evenly, and obtain B component;

[0042] d. Add component B into the stirring tank of A, stir and mix with component A evenly, use amine neutralizer to adjust the pH value of the mixture to 7.0-7.5, and prepare water-based electroplating varnish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com