Supercritical carbon dioxide based thermal stepped utilization method and system thereof

A carbon dioxide and supercritical technology, applied in steam applications, steam engine installations, machines/engines, etc., can solve the problems of increasing the complexity of the supercritical carbon dioxide cycle system, difficult to adapt to the load operating conditions, and increasing the difficulty of operation control, and achieve the The effect of shortening the running time under downtime conditions, improving economic competitiveness, and reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

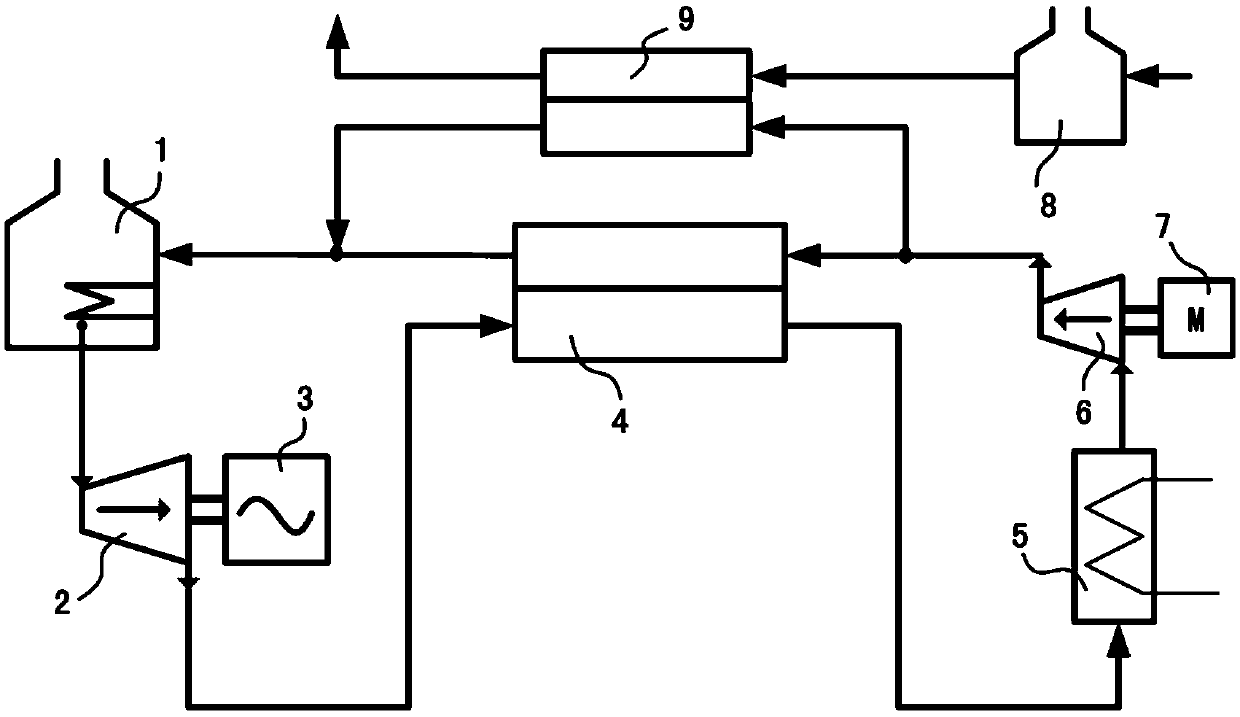

[0027] The cascade heat utilization method based on supercritical carbon dioxide includes passing the supercritical carbon dioxide through the high temperature heat source 1 turbine 2, the high temperature measurement of the main regenerator 4, the cooler 5, and the compressor 6, and then input to the main regenerator On the low temperature side of 4, the supercritical carbon dioxide in the low temperature side of the main regenerator 4 exchanges heat with the supercritical carbon dioxide in the high temperature measurement of the main regenerator 4 and then returns to the high temperature heat source 1 to form a cycle.

[0028] The circulation system contains two sets of independent heat sources: high temperature heat source 1 and medium and low temperature heat source 8. The supercritical carbon dioxide flowing through the compressor 6 is divided into two ways. One way supercritical carbon dioxide passes through the low temperature side of the main regenerator 4 for heat exchange...

Embodiment 2

[0030] A heat cascade utilization system based on supercritical carbon dioxide, including high temperature heat source 1, turbine 2, generator 3, main regenerator 4, cooler 5, compressor 6, electric motor 7, medium and low temperature heat source 8, branch regenerator 9 .

[0031] The high temperature heat source 1 is connected to the inlet of the turbine 2, the outlet of the turbine 2 is connected to the high temperature side inlet of the main regenerator 4, and the high temperature side outlet of the main regenerator 4 is connected to the inlet of the cooler 5. The cooler The outlet of 5 is connected to the inlet of compressor 6, and the outlet of compressor 6 is divided into two paths, one is connected to the low temperature side inlet of the main regenerator 4, and the other is connected to the low temperature side inlet of the branch regenerator 9 , The low-temperature side outlet of the main regenerator 4 merges with the low-temperature side outlet of the branch regenerator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com