Method and system for thawing based on water tank

A sink and brine technology, applied in food science, food preservation, application, etc., can solve the problems of accelerating propionaldehyde, long thawing time, low air heat transfer coefficient, etc., and achieve the effect of ensuring the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

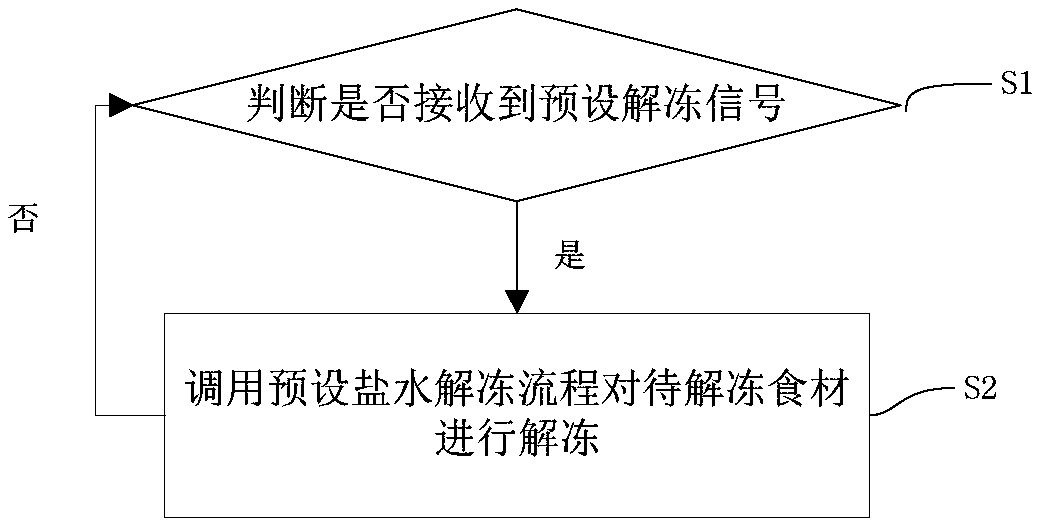

[0060] This embodiment provides a method based on tank thawing, such as figure 1 As shown, this method includes:

[0061] S1: judging whether a preset unfreezing signal is received;

[0062] S2: If yes, call the preset saline thawing process to thaw the ingredients to be thawed.

[0063] Further preferably, in this embodiment, there are two judgment methods for judging whether a preset thawing signal is received, the first is to receive the user’s preset thawing signal; the second is to receive a placement signal that the food to be thawed is placed in the water tank .

[0064] The first type of receiving the user's preset defrosting signal can be a defrosting button arranged on the water tank, and the preset defrosting signal can be received when it is received that the user has turned on the defrosting button on the sink.

[0065] The second signal for receiving the food to be thawed and placed in the water tank can be that a temperature sensor is installed at the bottom ...

Embodiment 2

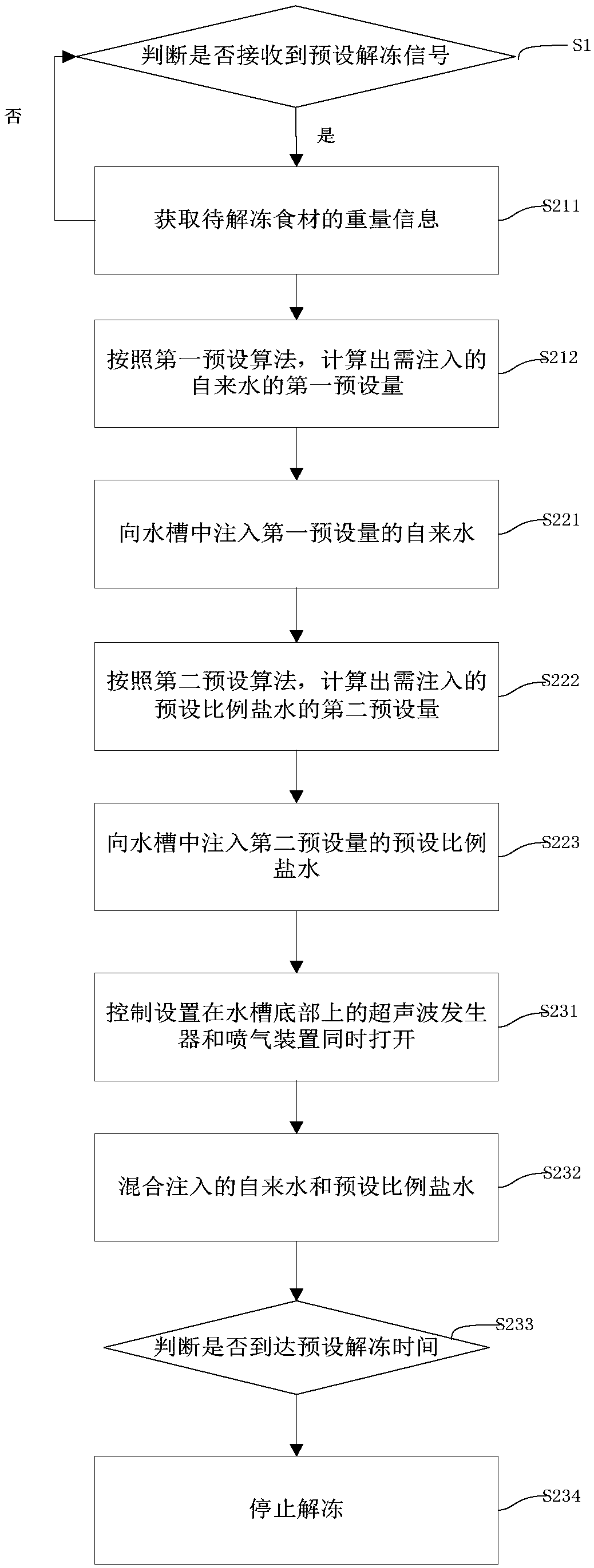

[0069] This embodiment provides a method based on tank thawing, such as figure 2 As shown, compared with the method provided in Embodiment 1, this method also includes:

[0070] Further, the preset brine thawing process includes:

[0071] S21: Inject a first preset amount of tap water into the water tank;

[0072] S22: Injecting a second preset amount of salt water with a preset ratio into the water tank;

[0073] S23: mixing tap water and salt water with a preset ratio and accelerating the flow of water in the tank through air bubbles, and thawing the ingredients to be thawed;

[0074] S24: The thawing is completed, and the water in the water tank is drained.

[0075] Specifically, the preset saline thawing process is as follows: firstly, the preset thawing signal is received, and after receiving the preset thawing signal, the preset saline thawing process is invoked, wherein the preset saline thawing process is:

[0076] First inject the first preset amount of tap water...

Embodiment 3

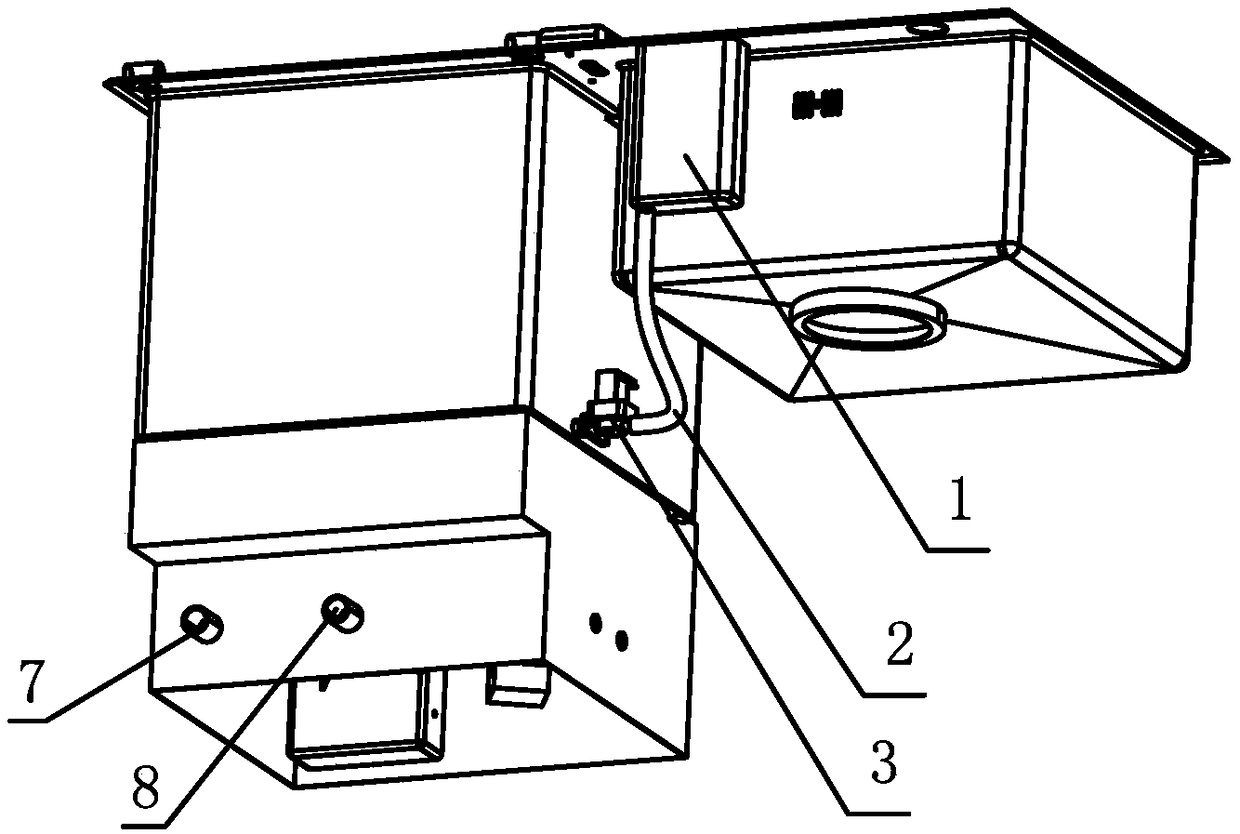

[0101] This embodiment provides a system based on tank thawing, such as Figure 3 to Figure 4 As shown, the system includes:

[0102] The receiving signal module is used to receive the preset defrosting signal;

[0103] The thawing module is used to call the preset saline thawing process to thaw the food to be thawed when the preset thawing signal is received.

[0104] Further, the unfreezing module includes:

[0105] Sink, brine tank, water inlet, brine solenoid valve, ultrasonic generator, air jet, drain, connecting pipe, and main control panel,

[0106] One end of the water inlet is connected to one end of the water pipe, and the other end is arranged at the bottom of the water tank through the water inlet valve for injecting tap water into the water tank through the water pipe;

[0107] The brine tank is set on one side of the water tank, and the bottom of the brine tank is connected to the brine solenoid valve set on the side of the water tank through a connecting pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com