Columnar material surface removing device and sugar cane peeling machine

A material and columnar technology, which is applied in the field of columnar material surface removal devices and sugarcane peeling machines, can solve the problems of affecting the peeling effect, unhygienic, slow peeling speed, etc., and achieve good peeling effect, high work efficiency and convenience. The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

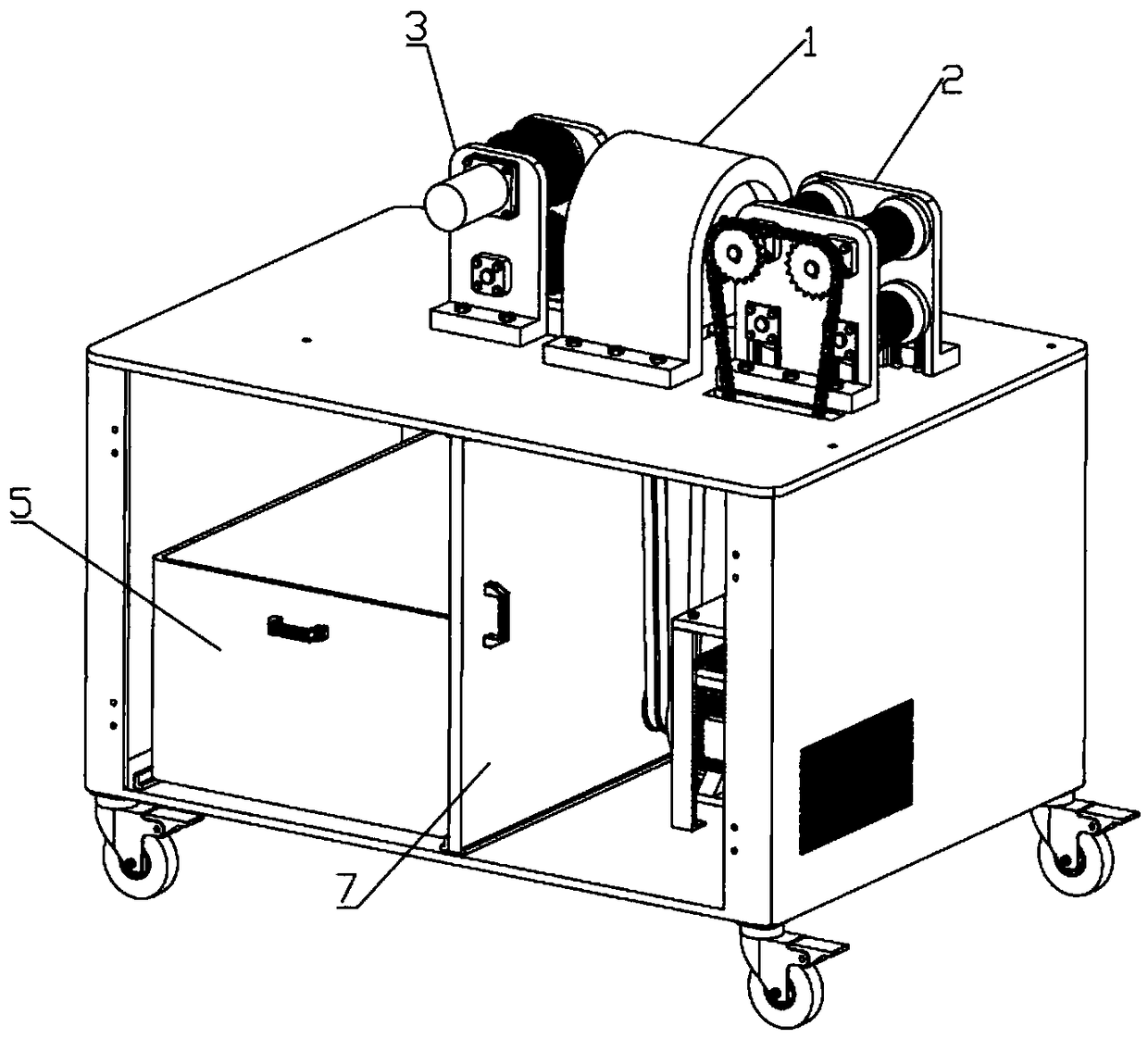

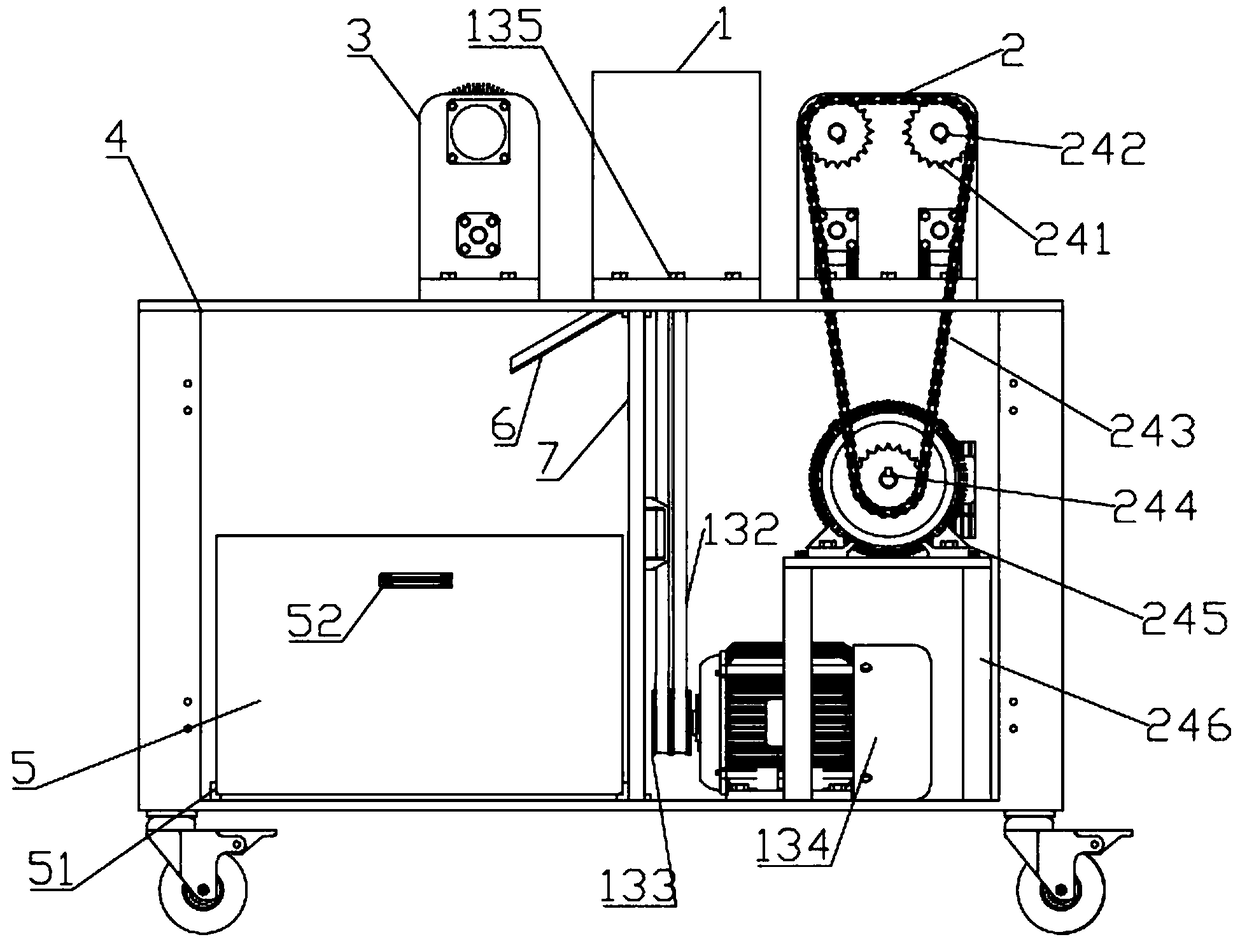

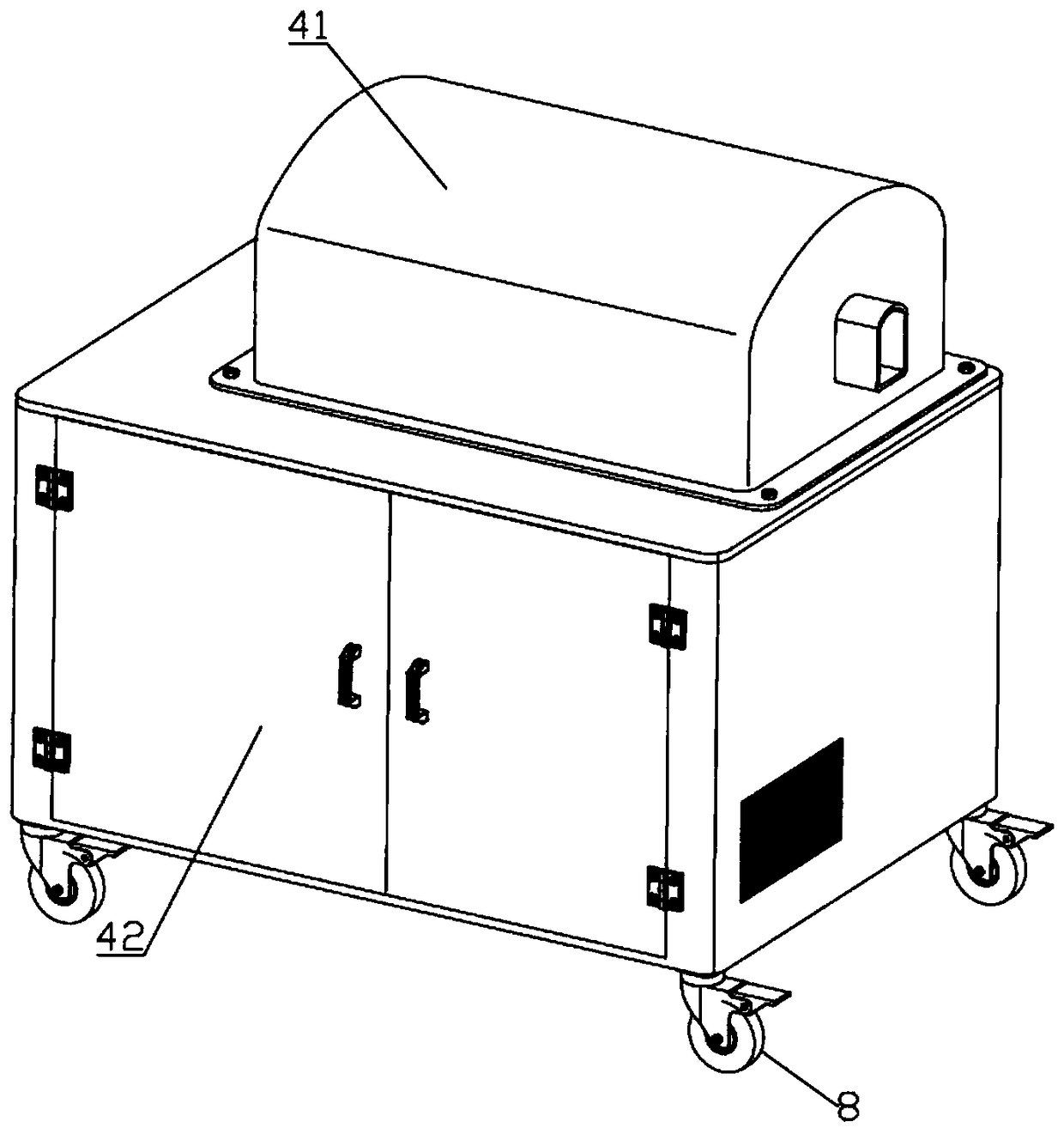

[0025] Such as Figures 1 to 3 Shown is the structural representation of the present invention, a kind of cylindrical material surface removal device, comprises frame 4 and the cutting mechanism 1 that is arranged on frame 4, also includes feeding mechanism 2 and cleaning structure 3, feeding mechanism 2, cutting Mechanism 1 and cleaning structure 3 are arranged in sequence from front to back, and the materials enter the cutting mechanism 1 from the feeding mechanism 2 and then to the cleaning structure 3. Of course, the feeding mechanism 2 can also be set behind the cutting mechanism 1. The material can provide the corresponding feeding force.

[0026] Figure 4 Schematic diagram of the cutting mechanism; Figure 5 for Figure 4 The front view of the cutting mechanism 1 includes a cutter head 11, a cutter 12 arranged on the cutter head 11, and a transmission device 13 that drives the cutter head 11 to rotate. The center of the cutter head 11 is provided with a through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com