Ceramide lipidosome and preparation method thereof

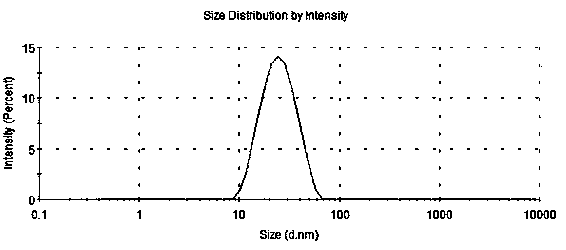

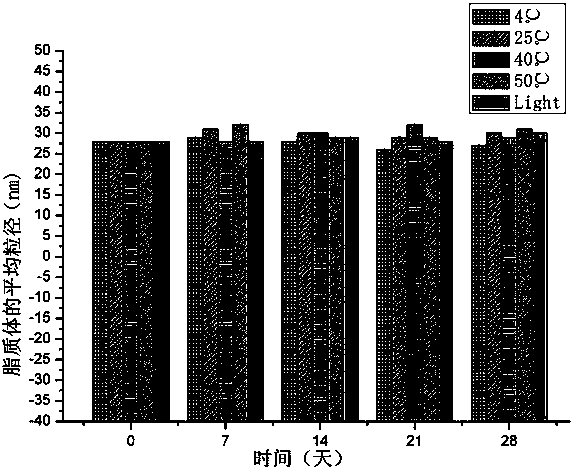

A technology of ceramide lipid and ceramide, which is applied in the field of ceramide liposome and its preparation, can solve the problems of limiting the wide application of ceramide, and achieve the effects of good moisturizing effect, good water dispersibility and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of preparation method of ceramide liposome adopts the following steps:

[0025] A. Weigh 7.5g of ceramide, 3g of cholesterol, 4.5g of fatty acid, 8.5g of ceteth-25, and 0.5g of glyceryl stearate. After weighing, put them in a 150mL beaker and place them in a water bath at 88°C for 200r / min Stir until it melts evenly to obtain an oil phase;

[0026] B. Weigh 5g of deionized water, heat it in a water bath to 88°C, add it into the oil phase obtained in step 1 under the condition of stirring at 200r / min, then naturally cool it to 32°C under the condition of stirring, and then heat it to 88°C in a water bath, so high The low temperature cycle was performed twice, and the obtained solution was homogenized once under a pressure of 800 bar to obtain an emulsion;

[0027] C. Weigh 48g of deionized water, 5g of lecithin, and 18g of sorbitol, and dissolve them uniformly in a water bath at 88°C to obtain the outer aqueous phase;

[0028] D. Slowly inject the...

Embodiment 2

[0030] Embodiment 2: a kind of preparation method of ceramide liposome adopts the following steps:

[0031] A. Weigh 2.5g of ceramide, 1g of cholesterol, 1.5g of fatty acid, 5.5g of glyceryl myristate, and 212g of steareth-212g. After weighing, put it into a 150mL beaker and place it in a water bath at 85°C at 200r / min. Stir until it melts evenly to obtain an oil phase;

[0032] B. Weigh 6g of deionized water, heat it in a water bath to 85°C, add it into the oil phase obtained in step 1 under the condition of stirring at 200r / min, then naturally cool it to 35°C under the condition of stirring, and then heat it to 85°C in a water bath, so high The low temperature cycle was performed twice, and the obtained solution was homogenized once under a pressure of 1000 bar to obtain an emulsion;

[0033] C. Weigh 52.5g of deionized water, 19g of sorbitol, and 10g of lecithin, and dissolve them uniformly in a water bath at 85°C to obtain an outer aqueous phase;

[0034] D. Slowly injec...

Embodiment 3

[0036] Embodiment 3: a kind of preparation method of ceramide liposome adopts the following steps:

[0037] A. Weigh 5g of ceramide, 2g of cholesterol, 3g of fatty acid, 3g of Tween 80, 0.5g of Span 80, and 6g of glyceryl stearate, weigh them and put them in a 150mL beaker, and put them in a 90°C water bath at 200r / min Stir until melted evenly, the oil phase;

[0038]B. Weigh 5g of deionized water, heat it in a water bath to 90°C, and add it to the oil phase obtained in step 1 under the condition of stirring at 200r / min, then naturally cool it to 40°C under the condition of stirring, and then heat it to 90°C in a water bath, so high Low temperature cycle 3 times, homogenize the obtained solution once under 1000 bar pressure, to obtain emulsion;

[0039] C. Weigh 48.5g of deionized water, 20g of sorbitol, and 7g of lecithin, and dissolve them uniformly in a water bath at 90°C to obtain the outer aqueous phase;

[0040] D. Slowly inject the emulsion obtained in step B into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com