Kitchen waste recovery and utilization device

A technology for kitchen waste and waste, applied in the field of kitchen waste recycling devices, can solve the problems of equipment body damage, waste disposal and reuse trouble, blockage, etc., so as to improve work efficiency, prevent blockage, improve effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

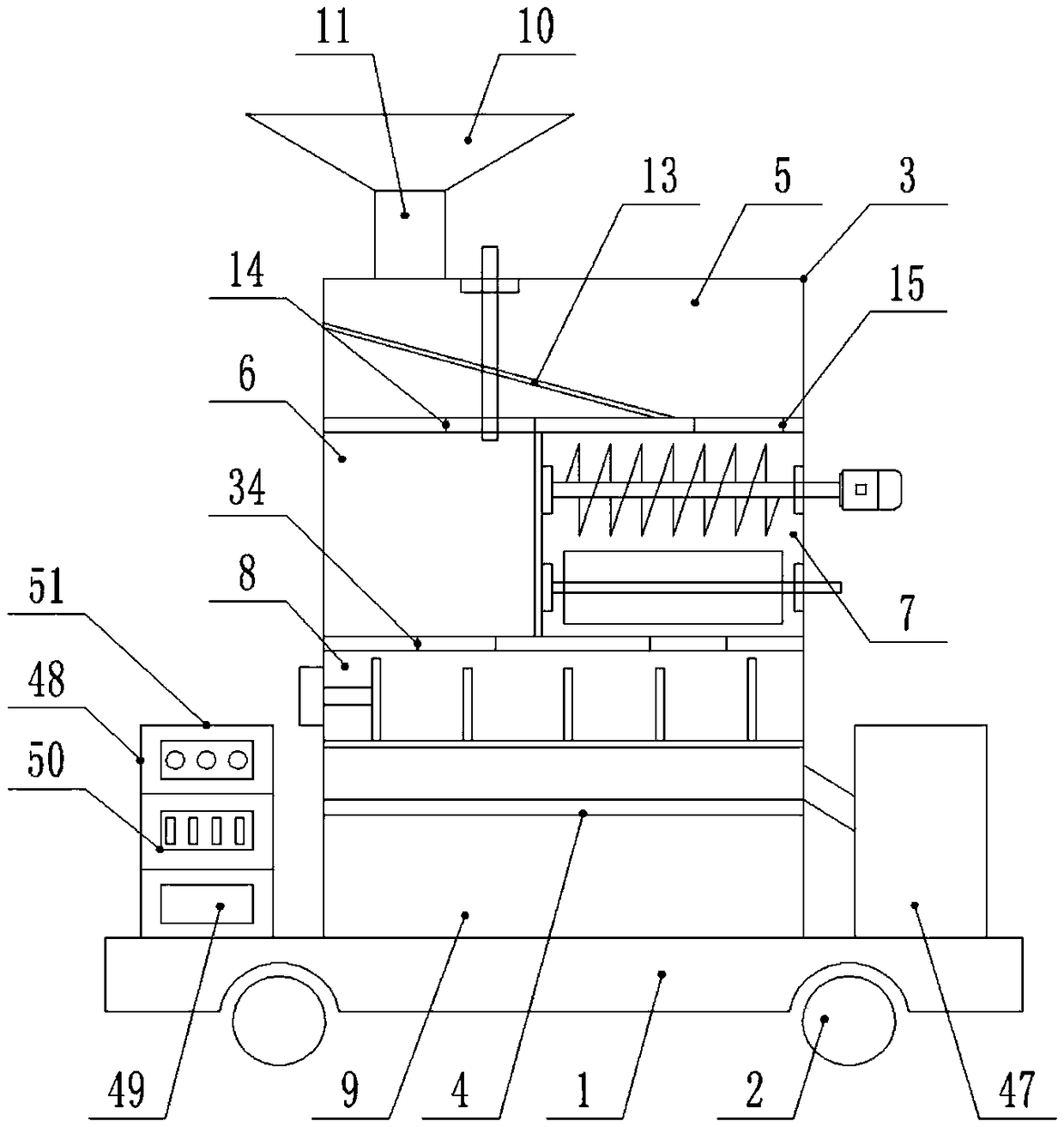

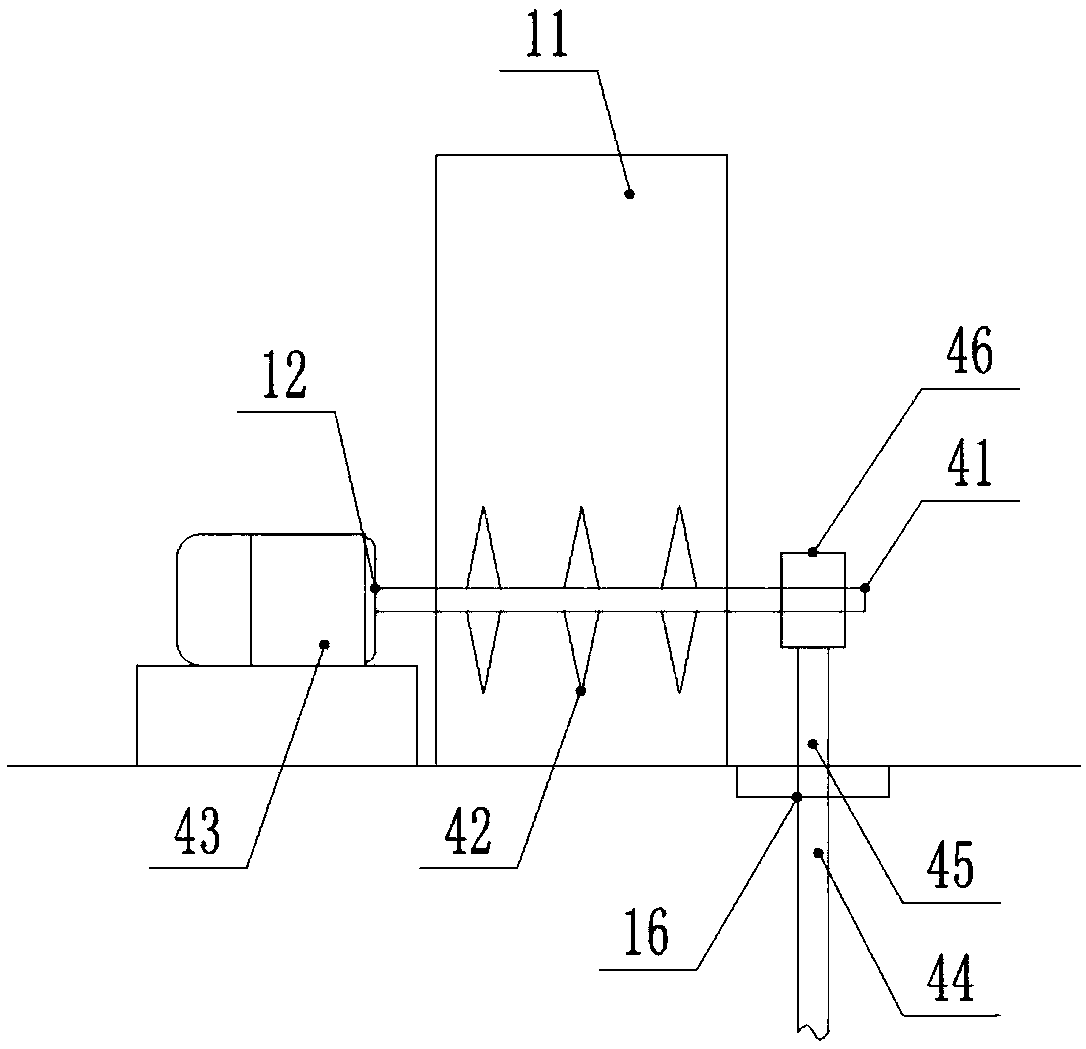

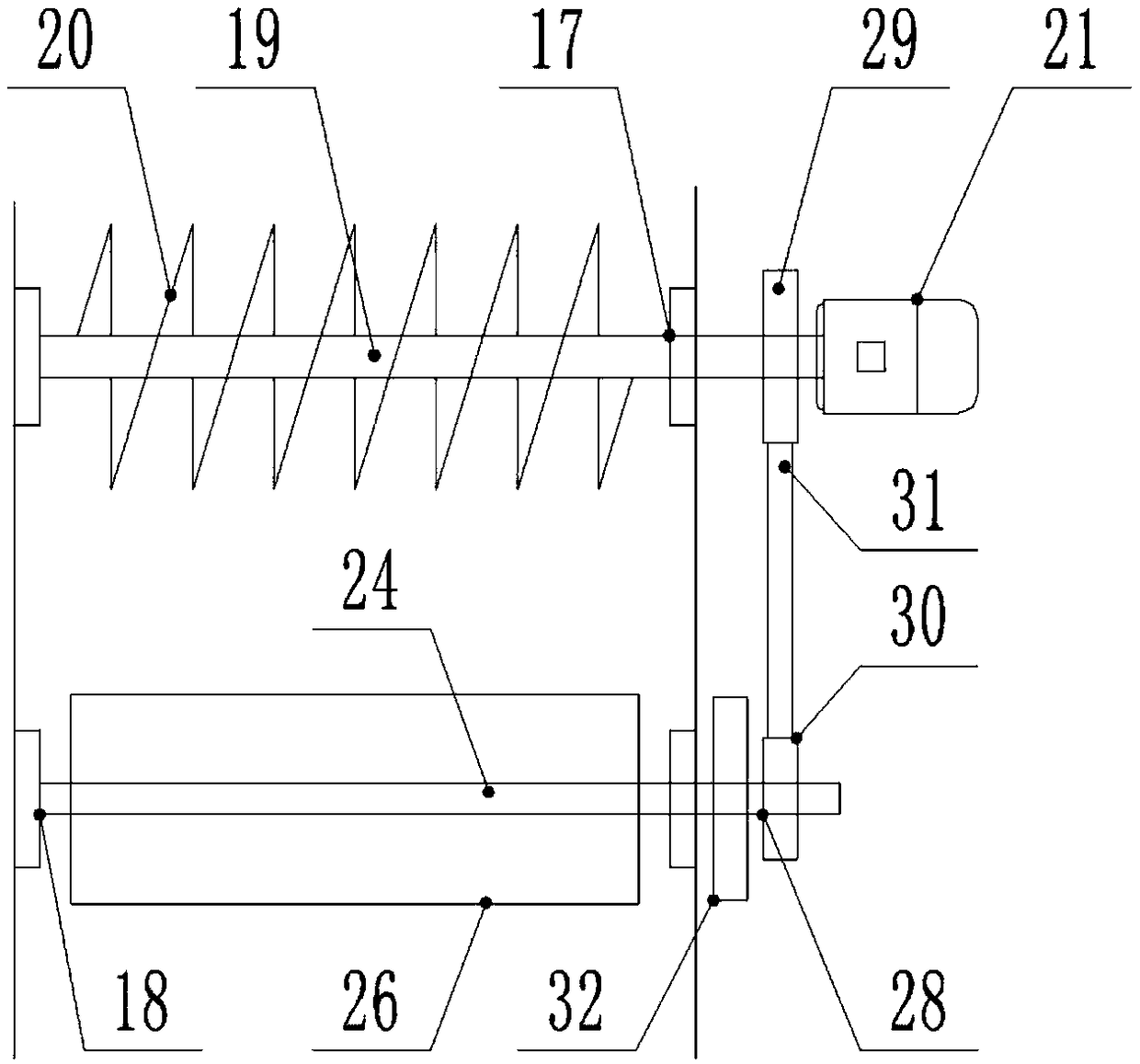

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, a kitchen waste recycling device includes an installation base 1, moving wheels 2 are provided at the four corners of the lower end of the installation base 1, and a simple waste disposal box 3 is provided at the upper end of the installation base 1. The waste simple treatment box 3 is provided with a number of partitions 4 through the inner cavity to divide the inner cavity from top to bottom into a feeding chamber 5, a left feeding channel 6, a right cutting chamber 7, and a solid-liquid separation chamber 8 And the oil-water separation chamber 9, the upper side of the feed chamber 5 is provided with a feed funnel 10 and the feed funnel 10 communicates with the feed chamber 5 through the feed cylinder 11 provided at its lower end, the feed A simple rotating device 12 is provided in the cylinder 11, and an inclined screen 13 is provided at the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com