Automatic argon arc welding equipment for liquid storage tank

A technology of argon arc welding and liquid storage tank, which is applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of low production efficiency and low degree of automation, and achieves the improvement of welding quality, transmission efficiency and rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

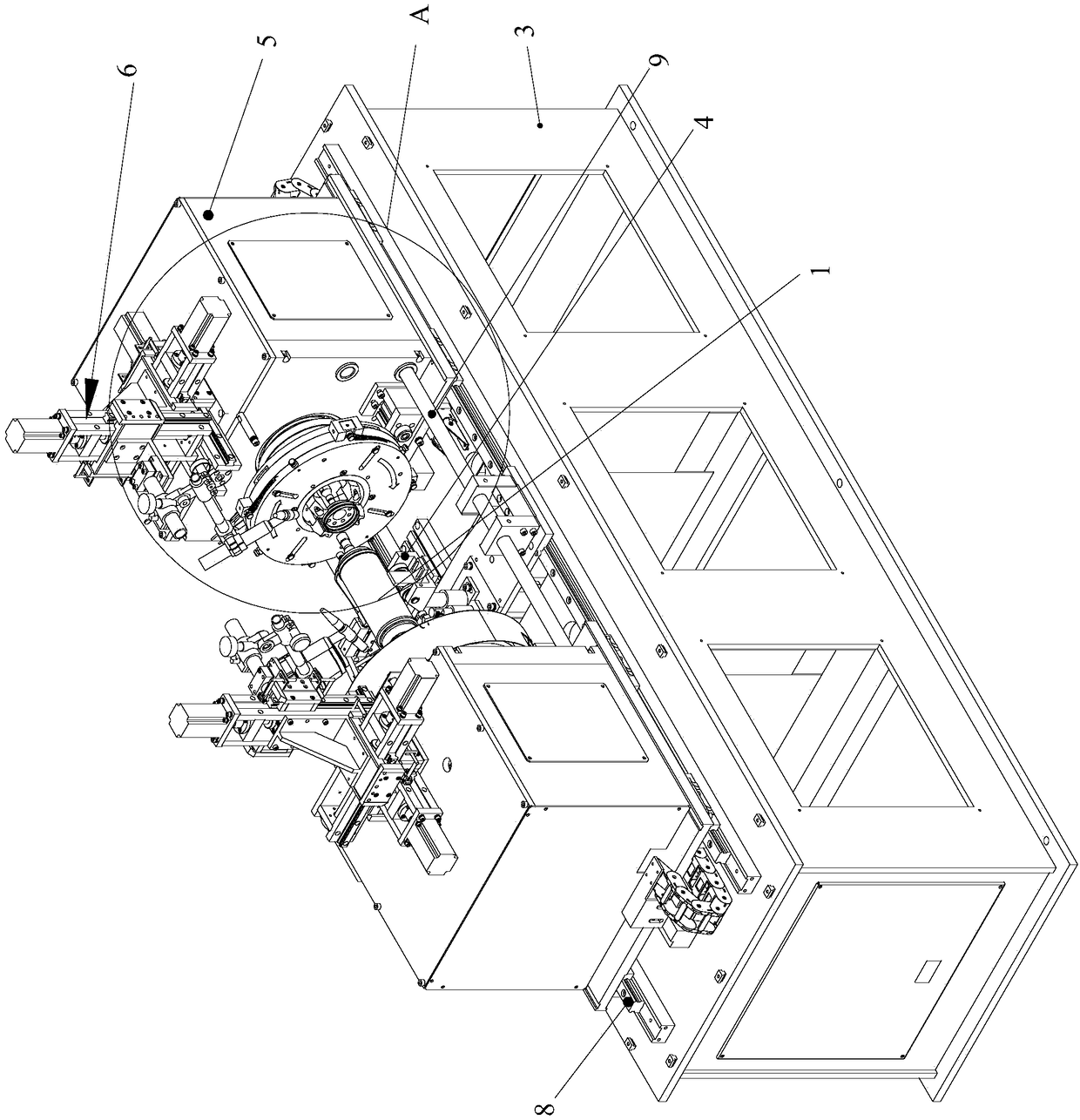

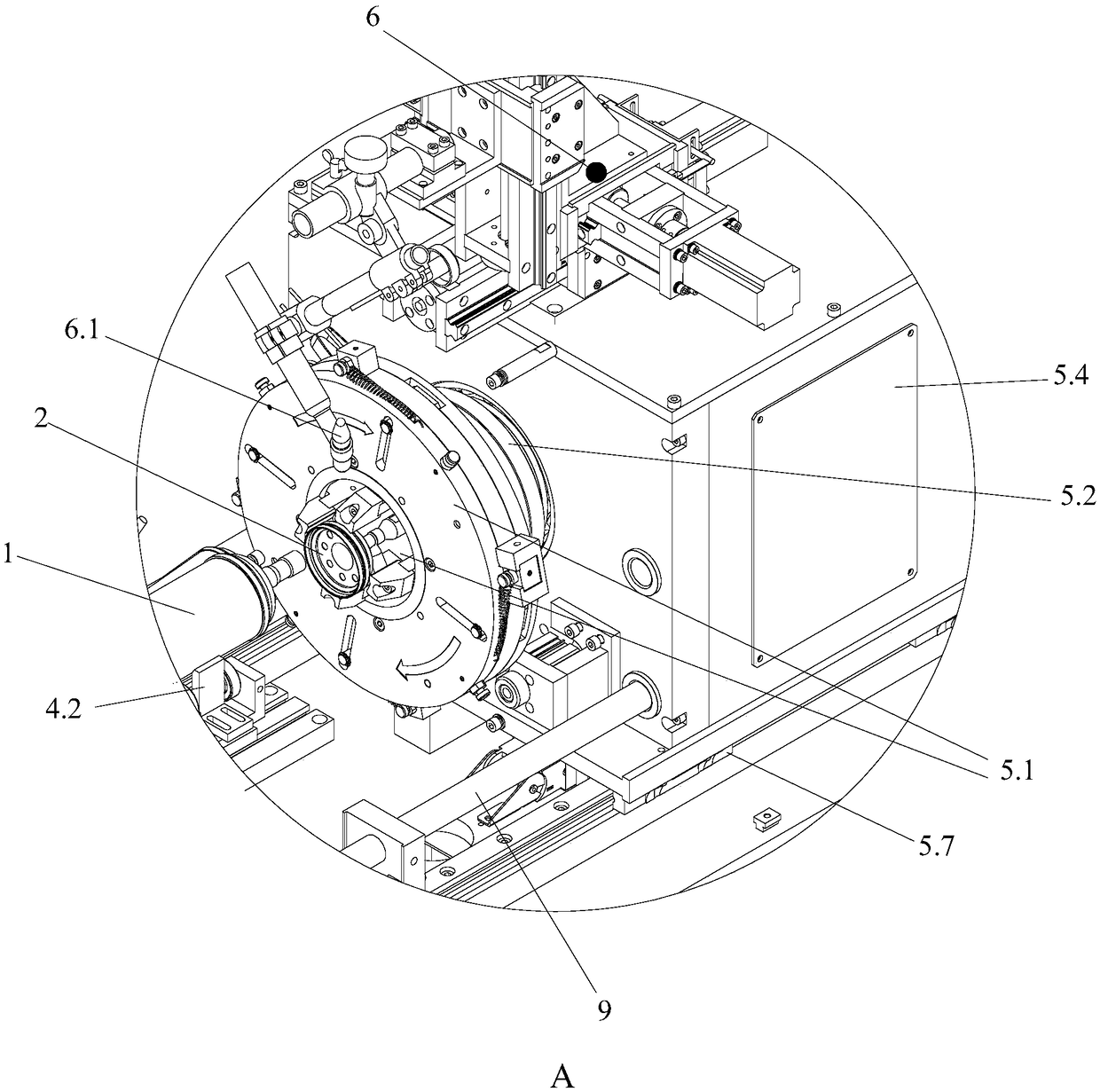

[0062] Such as Figure 1 to Figure 9 As shown, an automatic argon arc welding equipment for a liquid storage tank according to the present invention is used for positioning and welding the liquid storage tank body 1 and two end caps 2; including:

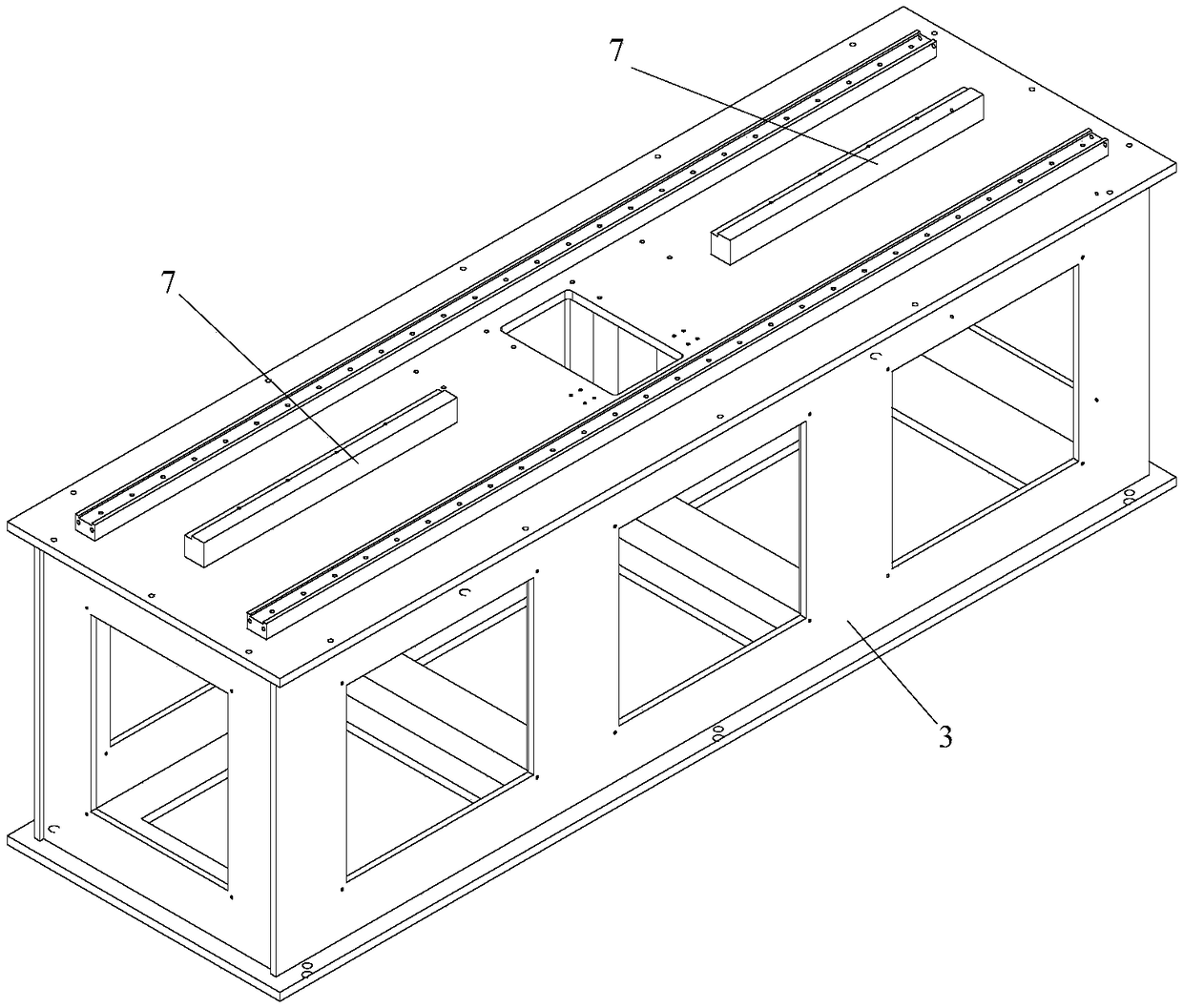

[0063] Rack 3;

[0064] The clamping and rotating mechanism for positioning the liquid storage tank body 1 and the two end caps 2, the clamping and rotating mechanism includes a holding device 4 for holding the liquid storage tank body 1 and for clamping the end caps 2 and A dual-spindle clamping device that can drive the end cover 2 to rotate;

[0065] Linear traveling device for linear movement of dual-spindle clamping device;

[0066] A welding device 6 for welding the liquid storage tank body 1 and the end cover 2;

[0067] Gas protection device for cooling and anti-oxidation during welding;

[0068] Among them, the linear walking device is arranged on the frame 3, the double-spindle clamping device is two spindle bases 5 wi...

Embodiment 2

[0080] The only difference between this embodiment and the implementation one is that: Figure 10 As shown, the clamp is a cylindrical sleeve 17, and the sleeve 17 is matched with the end cap. The set 17 can be matched and fixed with the end cap by adopting an existing structure. For example, a clip for engaging and fixing with the end cap can be provided at the end of the set, and the clip can be engaged and fixed with the end cap.

[0081] Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com