Production method of rice vinegar

A production method and technology for rice vinegar, which are applied in the field of rice vinegar production with a variety of microbial gradient fermentations, can solve problems such as lack of microbial gradient fermentation method alcohol fermentation, and achieve the effects of improving the utilization rate of raw materials and improving the aroma and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

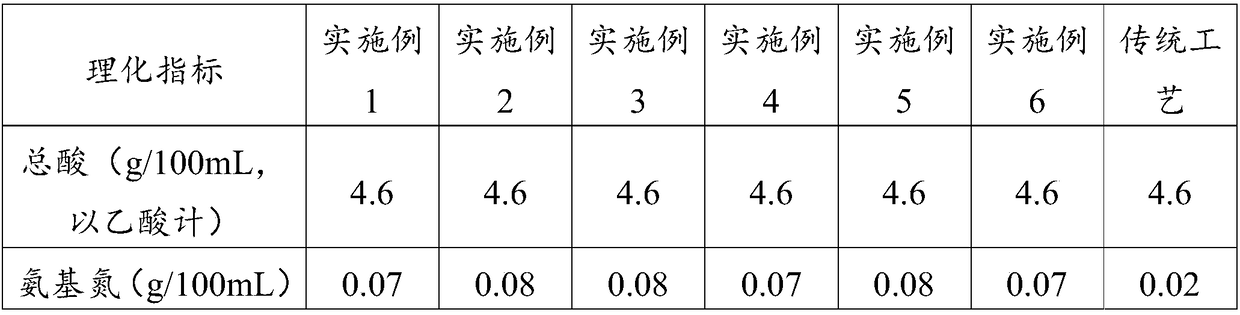

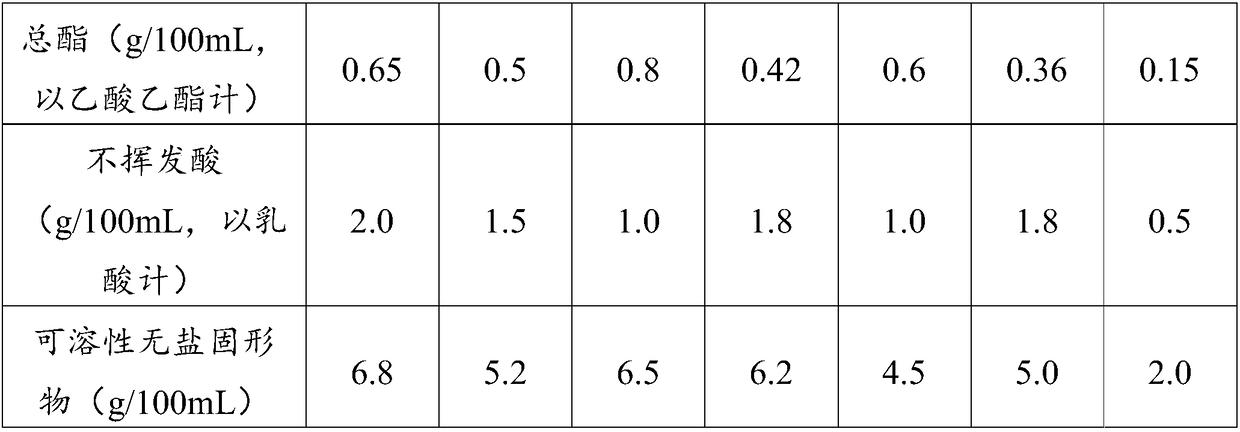

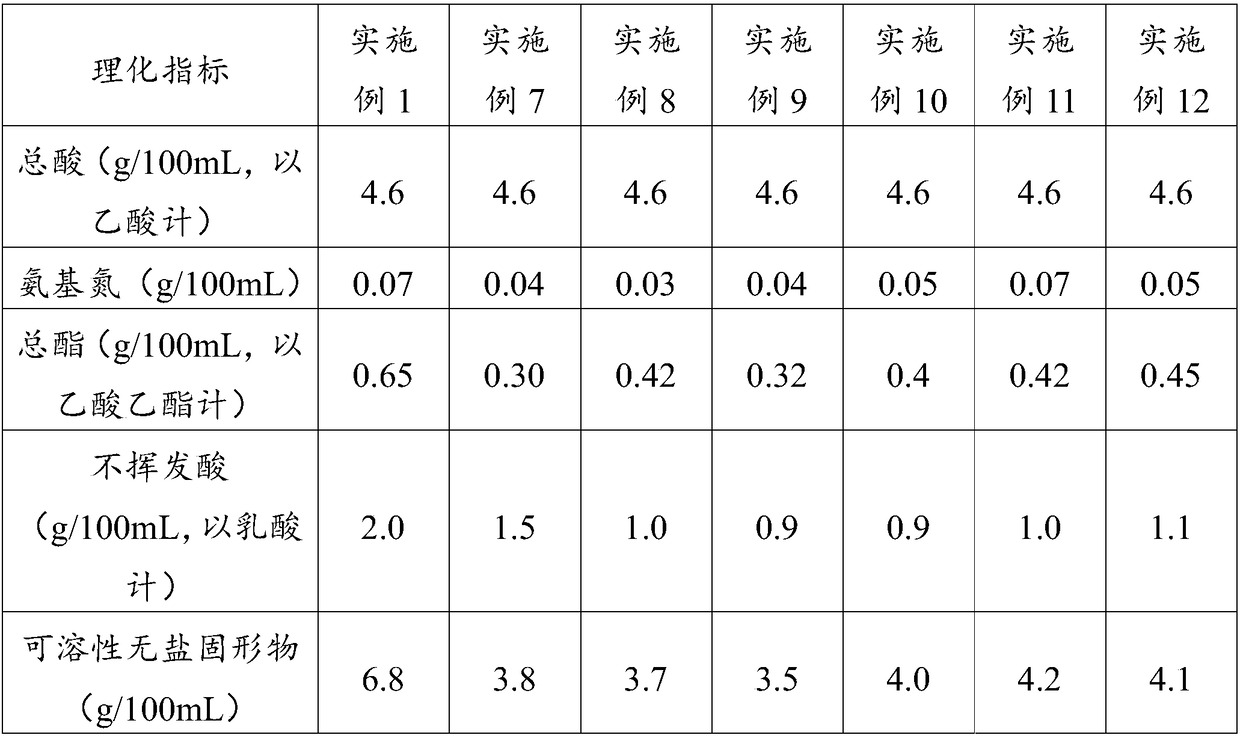

Examples

Embodiment 1

[0026] A kind of embodiment of the production method of rice vinegar of the present invention, the production method of rice vinegar described in the present embodiment comprises the following steps:

[0027] (1), after adding water 4 times the weight of the rice to the rice, add 0.5% α-amylase of the weight percentage of the rice, heat to 92°C, stir, heat and cook for 2 hours to completely liquefy the starch;

[0028] (2), cooling down to 50°C, adding 1% bran koji of the weight percentage of rice, cultivating at 50°C for 4 days, carrying out part of the saccharification process and the formation of flavor substances;

[0029] (3), be cooled to 33 ℃, add 1% rhizopus koji, yellow rice wine koji and rice wine koji of the weight percentage of rice, the ratio of the weight of rhizopus koji, yellow rice wine koji and rice wine koji is: rhizopus koji: yellow rice wine Koji: rice wine koji = 2:1:1, cultured at 33°C for 7 days, carrying out alcoholic fermentation while saccharificatio...

Embodiment 2

[0034] A kind of embodiment of the production method of rice vinegar of the present invention, the production method of rice vinegar described in the present embodiment comprises the following steps:

[0035] (1), after adding water 4 times the weight of the rice to the rice, add 0.5% α-amylase of the weight percentage of the rice, heat to 92°C, stir, heat and cook for 2 hours to completely liquefy the starch;

[0036] (2), cool down to 50°C, add bran koji and Dako 2% of the weight percentage of rice, the weight ratio of bran koji and Dako is: bran koji: Dakoji=1:1, at 50°C Cultivate for 4 days for partial saccharification and flavor formation;

[0037] (3), be cooled to 35 ℃, add 1% rhizopus koji, yellow rice wine koji and rice wine koji of the weight percentage of rice, the ratio of the weight of rhizopus koji, yellow rice wine koji and rice wine koji is: rhizopus koji: yellow rice wine koji : rice wine koji=3:1:1, cultivated at 35°C for 7 days, carried out alcoholic fermen...

Embodiment 3

[0042] A kind of embodiment of the production method of rice vinegar of the present invention, the production method of rice vinegar described in the present embodiment comprises the following steps:

[0043](1), after adding water 4 times the weight of the rice to the rice, add 0.5% α-amylase of the weight percentage of the rice, heat to 92°C, stir, heat and cook for 2 hours to completely liquefy the starch;

[0044] (2), cooling to 50 DEG C, adding 2% bran koji of the weight percentage of rice, cultivating at 50 DEG C for 4 days, carrying out part of the saccharification process and the formation of flavor substances;

[0045] (3), be cooled to 33 ℃, add 1% rhizopus koji, yellow rice wine koji and rice wine koji of the weight percentage of rice, the ratio of the weight of rhizopus koji, yellow rice wine koji and rice wine koji is: rhizopus koji: yellow rice wine koji : rice wine koji=2:0.5:1, cultivated at 33°C for 7 days, carried out alcoholic fermentation while saccharific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com