A kind of processing method of aluminum-silicon alloy modification agent

The technology of an aluminum-silicon alloy and a processing method is applied in the processing field of the aluminum-silicon alloy modifier, which can solve the problems of large size of the second phase, complicated preparation process, etc., so as to ensure long-term effect, simple processing method and good versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Aluminum and strontium were added to the graphite crucible at a mass ratio of 9.0:1.0 (wt%), put into a heating furnace for melting, protected by argon, the melting temperature was 750°C, and kept for 60 minutes. Then, pour it into a water-cooled copper mold and cast it into an ingot, and the casting is cooled to 50°C and taken out;

[0035] Heating the casting to 500°C for rolling, keeping the temperature at 500°C during the rolling process, with a single-pass deformation of 10%, until the plate with a deformation of 90% of the casting is quickly cooled to room temperature to obtain a modified aluminum-silicon alloy agent.

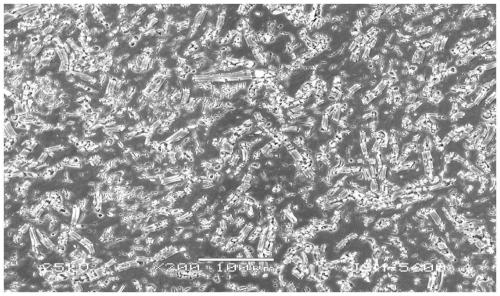

[0036] The grain size of the second phase of the product prepared in Example 1 is obviously reduced, and the average grain size is less than 10 μm according to statistics.

Embodiment 2

[0038] Aluminum and strontium were added to the graphite crucible at a mass ratio of 9.0:1.0 (wt%), put into a heating furnace for melting, protected by argon, the melting temperature was 800°C, and kept for 60 minutes. Then, pour it into a water-cooled copper mold and cast it into an ingot, and the casting is cooled to 50°C and taken out;

[0039] Heating the casting to 500°C for rolling, keeping the temperature at 500°C during the rolling process, with a single-pass deformation of 10%, until the plate with a deformation of 90% of the casting is quickly cooled to room temperature to obtain a modified aluminum-silicon alloy agent.

[0040] The grain size of the second phase of the product prepared in Example 2 is obviously reduced, and the average grain size is less than 10 μm according to statistics.

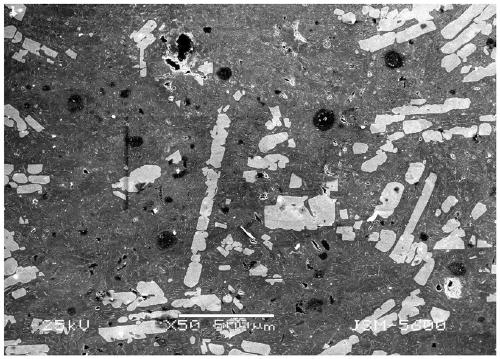

[0041] figure 1 is the microstructure picture of Al-Si alloy modifier prepared by traditional method, figure 1 It can be seen that the grain size is large, and the grain len...

Embodiment 3

[0046] Aluminum and strontium were added to the graphite crucible at a mass ratio of 9.0:1.0 (wt%), put into a heating furnace for melting, protected by argon, the melting temperature was 850°C, and kept for 60 minutes. Then, pour it into a water-cooled copper mold and cast it into an ingot, and the casting is cooled to 50°C and taken out;

[0047]Heating the casting to 500°C for rolling, keeping the temperature at 500°C during the rolling process, with a single-pass deformation of 10%, until the plate with a deformation of 90% of the casting is quickly cooled to room temperature to obtain a modified aluminum-silicon alloy agent.

[0048] The grain size of the second phase of the product prepared in Example 3 is obviously reduced, and the average grain size is less than 10 μm according to statistics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com