Fertilizing and ditching integrated equipment based on fertilizer mixing principle and used for camellia oleifera planting

A technology for fertilization and ditching and fertilizer is applied in the field of integrated fertilization and ditching equipment for Camellia oleifera planting, which can solve the problems of insufficient mixing, unbalanced fertilization effect, affecting the growth of Camellia oleifera, etc. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

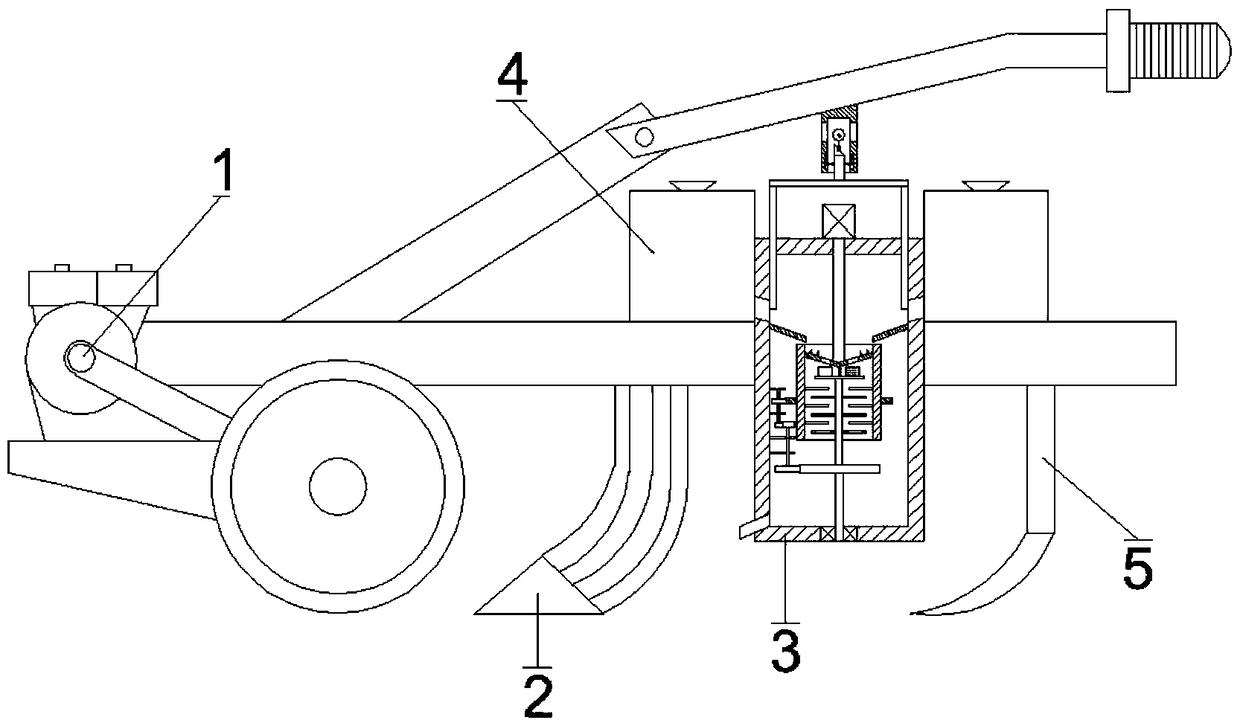

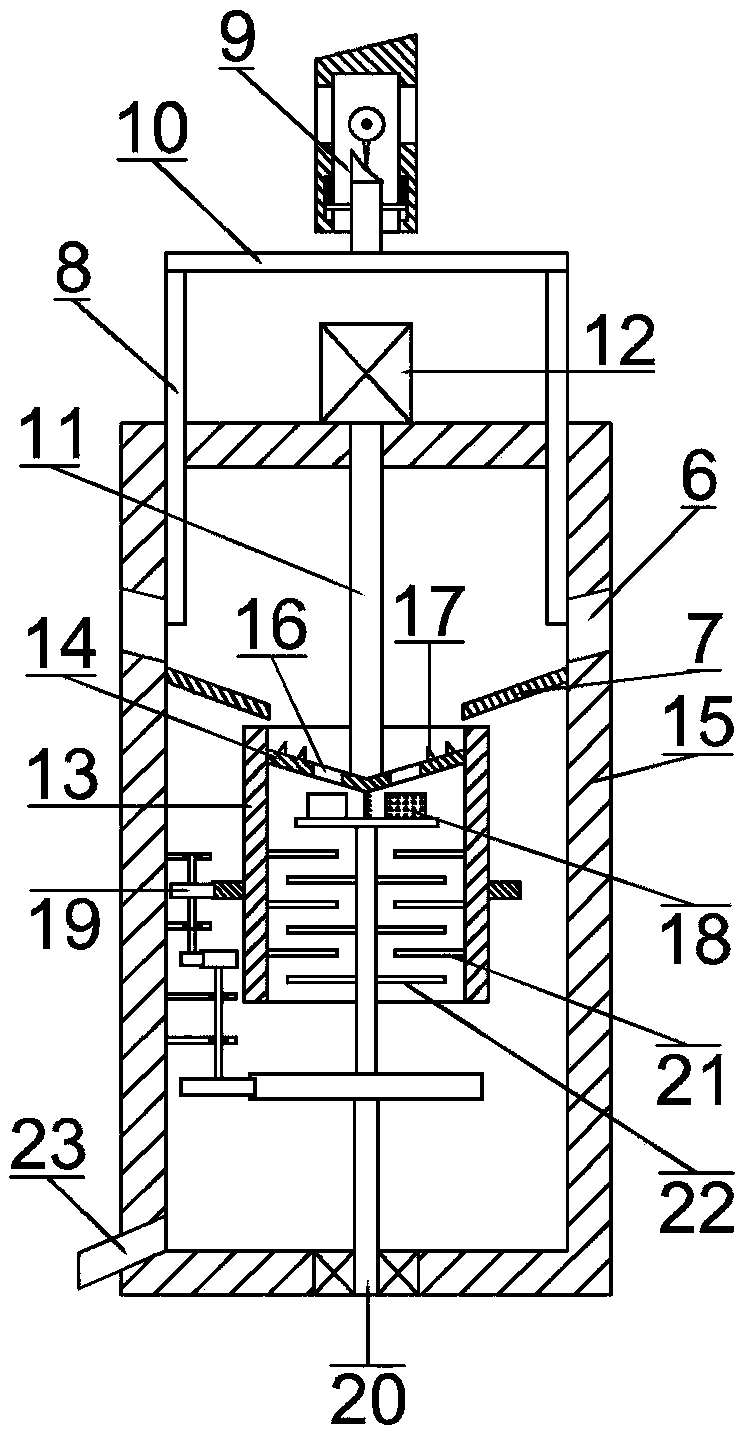

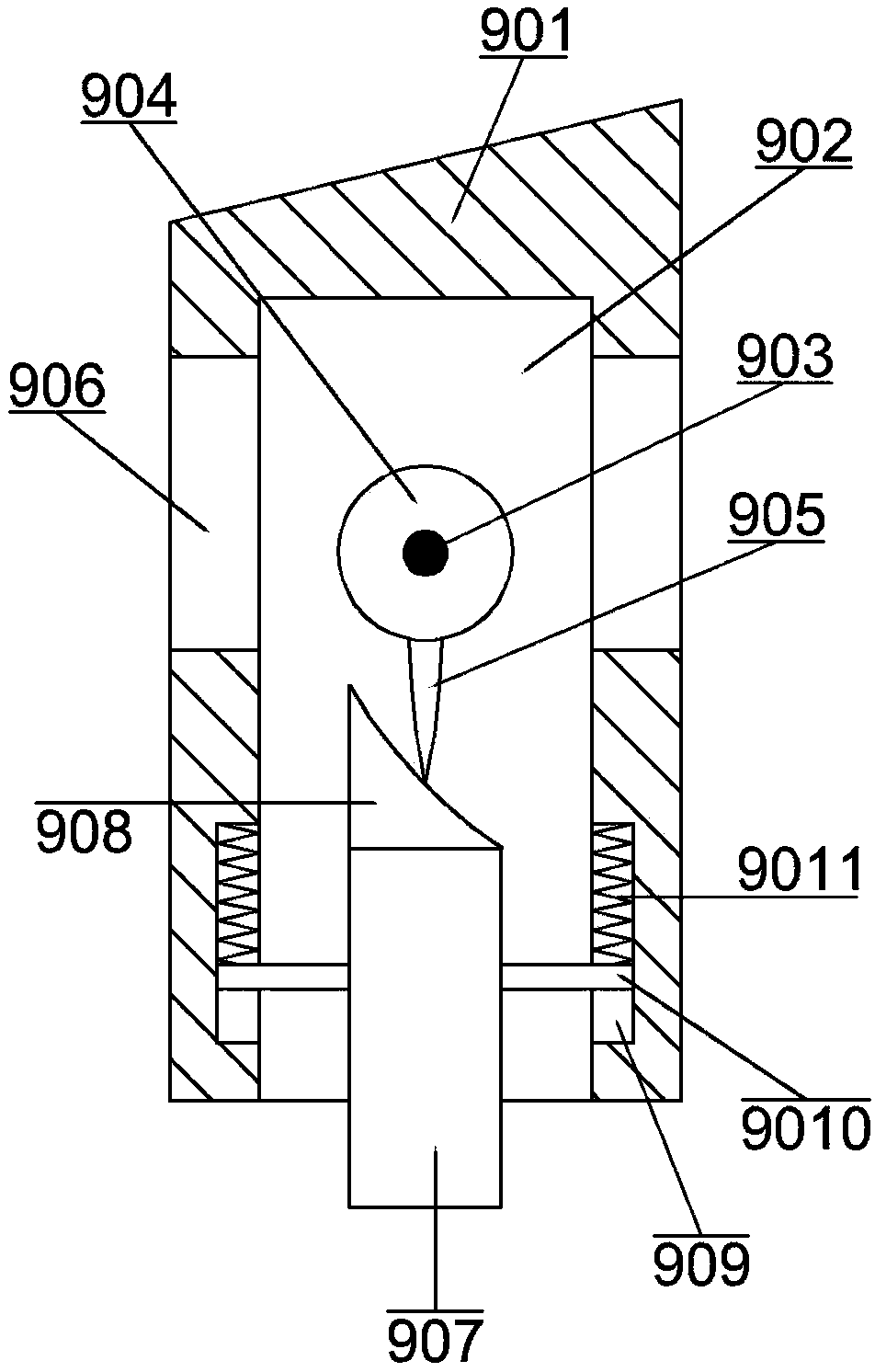

[0034] see figure 1 , figure 2 with image 3, in this embodiment, a fertilization and ditching integrated equipment for Camellia oleifera planting based on the principle of fertilizer mixing, comprising a tractor frame 1, a ditch opener 2 is arranged on the lower side of the tractor frame 1, and the right side of the ditch opener 2 A fertilizer mixing device 3 is arranged on the tractor frame 1, and two fertilizer boxes 4 are arranged symmetrically on the left and right sides of the fertilizer mixing device 3. The fertilizer boxes 4 are connected with the inside of the fertilizer mixing device 3. When more than two kinds of fertilizers are required, Also can be provided with two fertilizer boxes 4 here, is convenient to carry out mixed treatment to various fertilizers, and described fertilizer mixing device 3 comprises mixing box 15, and fertilizer box 4 communicates through opening 6 on the side wall of mixing box 15 , and the through hole 6 is provided with a blocking pla...

Embodiment 2

[0038] see figure 1 with figure 2 , the top of the mixing box 15 is rotatably connected with a second rotating shaft 11, the top of the second rotating shaft 11 is fixedly connected with the output shaft of the second motor 12 located on the upper side of the mixing box 15, and a mixing sleeve is arranged below the second rotating shaft 11 13. A V-shaped plate 14 is arranged inside the mixing sleeve 13, and the bottom end of the second rotating shaft 11 is fixedly connected to the V-shaped plate 14, and the upper surface of the V-shaped plate 14 is uniformly provided with a number of first mixing protrusions 17, and the V-shaped plate 14 is uniformly provided with a number of first mixing protrusions 17. A blanking hole 16 is provided on the type plate 14. When the two kinds of fertilizers enter the mixing box 15, the second motor 12 is started, and the second motor 12 drives the second rotating shaft 11 to rotate, and the second rotating shaft 11 is driven by the V-shaped pl...

Embodiment 3

[0043] see figure 2 with Image 6 The steering conversion device 19 includes a ring gear 191 arranged on the outer wall of the mixing sleeve 13, the left side of the ring gear 191 is meshed with a first gear 192, the first gear 192 is fixedly connected with a first rotating rod 193, the first The two ends of the rotating rod 193 are rotationally connected with two first support plates 194 fixedly arranged on the inner wall of the mixing box 15; the bottom end of the first rotating rod 193 is fixedly connected with a second gear 195, and the right side of the second gear 195 is engaged There is a third gear 196, the bottom end of the third gear 196 is fixedly connected with a second rotating rod 197, and the middle part of the second rotating rod 197 is rotationally connected with two second support plates 198 fixedly arranged on the inner wall of the mixing box 15; The bottom end of the second rotating rod 197 is fixedly connected with a fourth gear 199, and the right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com