Protein-polysaccharide composite thermal gel for food and preparation method of protein-polysaccharide composite thermal gel

A polysaccharide compounding and protein technology, applied in the field of food processing, can solve the problems of poor water holding capacity, single texture properties, poor mechanical properties of thermal gels, etc., to achieve improved mechanical properties and water holding capacity, efficient processing, and expanded applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

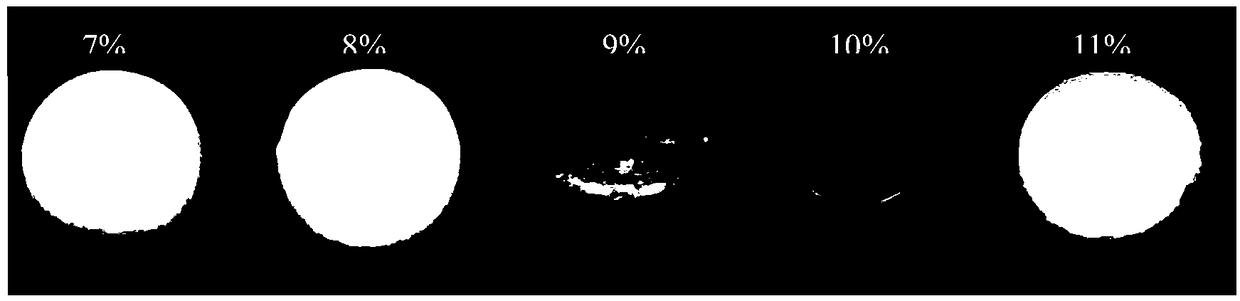

[0045] The dual-network thermogel provided in this example has the following components: 7% (w / v) soybean protein isolate, 1.5% (w / v) beet pectin, and laccase (100 nkat / g substrate). The substrates are soy protein isolate and beet pectin.

[0046] The specific process of its preparation is as follows:

[0047] 7 g of SPI was dissolved in 100 ml of distilled water, stirred thoroughly for 4 hours, and placed in a refrigerator at 4°C overnight to ensure that the SPI was fully hydrated to obtain a 7% (w / v) SPI solution. Add 1.5g SBP and magnetically stir for 4h until fully dissolved. Then add laccase (100nkat / g substrate), stir evenly, put it in a water bath at 40°C and keep it for 2 hours, then put it in a water bath at 90°C and heat it for 30 minutes, cool it quickly with flowing water, and place it at 4°C Refrigerate overnight to obtain SPI-SBP thermal gel.

[0048] The obtained SPI-SBP thermal gel was stored in a refrigerator at 4°C.

Embodiment 2

[0050] The dual-network thermal gel provided in this example has the following components: 8% (w / v) soybean protein isolate, 1.5% (w / v) beet pectin, and laccase (100nkat / g substrate). The substrates are soy protein isolate and beet pectin.

[0051] The specific process of its preparation is as follows:

[0052]Dissolve 8g of SPI in 100ml of distilled water, stir thoroughly for 4 hours, and place in a refrigerator at 4°C overnight to ensure that the SPI is fully hydrated to obtain an 8% (w / v) SPI solution. Add 1.5g SBP and magnetically stir for 4h until fully dissolved. Then add laccase (100nkat / g substrate), stir evenly, put it in a water bath at 40°C and keep it for 2 hours, then put it in a water bath at 90°C and heat it for 30 minutes, cool it quickly with flowing water, and place it at 4°C Refrigerate overnight to obtain SPI-SBP thermal gel.

[0053] The obtained SPI-SBP thermal gel was stored in a refrigerator at 4°C.

Embodiment 3

[0055] The dual-network thermal gel provided in this example has the following components: 9% (w / v) soybean protein isolate, 1.5% (w / v) beet pectin, and laccase (100nkat / g substrate). The substrates are soy protein isolate and beet pectin.

[0056] Its preparation specific process is as follows:

[0057] Dissolve 9 g of SPI in 100 ml of distilled water, stir thoroughly for 4 hours, and place in a refrigerator at 4°C overnight to ensure that the SPI is fully hydrated to obtain a 9% (w / v) SPI solution. Add 1.5g SBP and magnetically stir for 4h until fully dissolved. Then add laccase (100nkat / g substrate), stir evenly, put it in a water bath at 40°C and keep it for 2 hours, then put it in a water bath at 90°C and heat it for 30 minutes, cool it quickly with flowing water, and place it at 4°C Refrigerate overnight to obtain SPI-SBP thermal gel.

[0058] The obtained SPI-SBP thermal gel was stored in a refrigerator at 4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com