Lumbar vertebral puncture needle assembly with positioning and color rendering functions

A lumbar puncture and needle assembly technology, which is applied in the field of medical devices, can solve the problems of uncontrollable puncture depth and inaccurate positioning, and achieve the effect of avoiding collateral damage, avoiding dislocation, avoiding infection and sequelae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

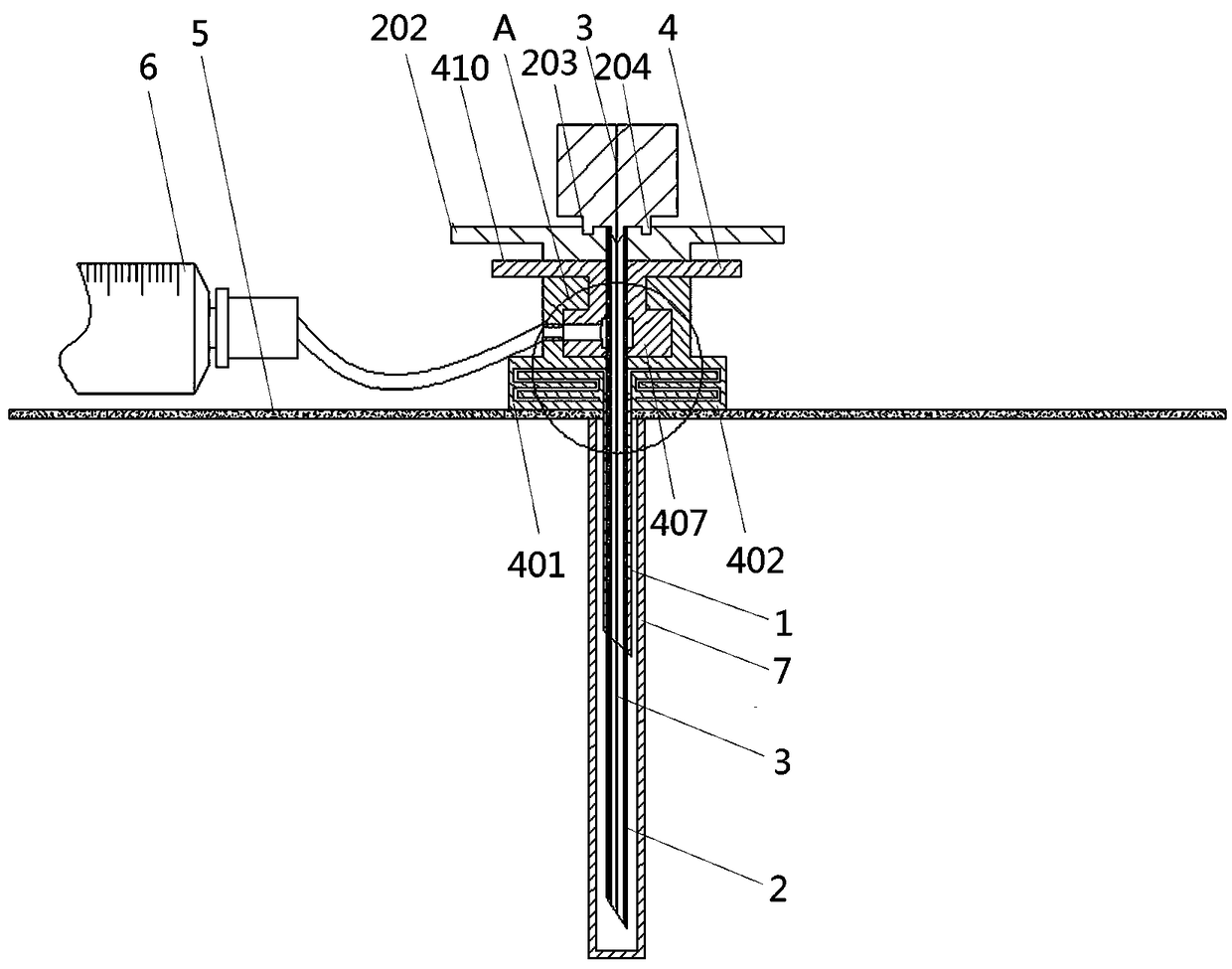

[0030] Embodiment 2, a lumbar puncture needle assembly with positioning and color rendering functions, the outer periphery of the lumbar puncture needle is provided with a penetration depth scale, and the setting of the penetration depth scale is not only convenient for the control of the first puncture depth, but also for re-examination. At the same time, you can refer to the depth of the last puncture record.

[0031] The holding end of the lumbar puncture needle 2 is provided with a booster plate 202 , the booster plate 202 is provided with a docking groove 203 , and the end of the needle core 3 is provided with a snap ring 204 matched with the docking groove 203 . By setting the booster plate, the puncture can be conveniently carried out, which can not only ensure the stability of the puncture, but also save labor. The setting of the docking groove and the retaining ring can ensure the accuracy of docking.

[0032] The other structures of this embodiment are the same as t...

Embodiment 3

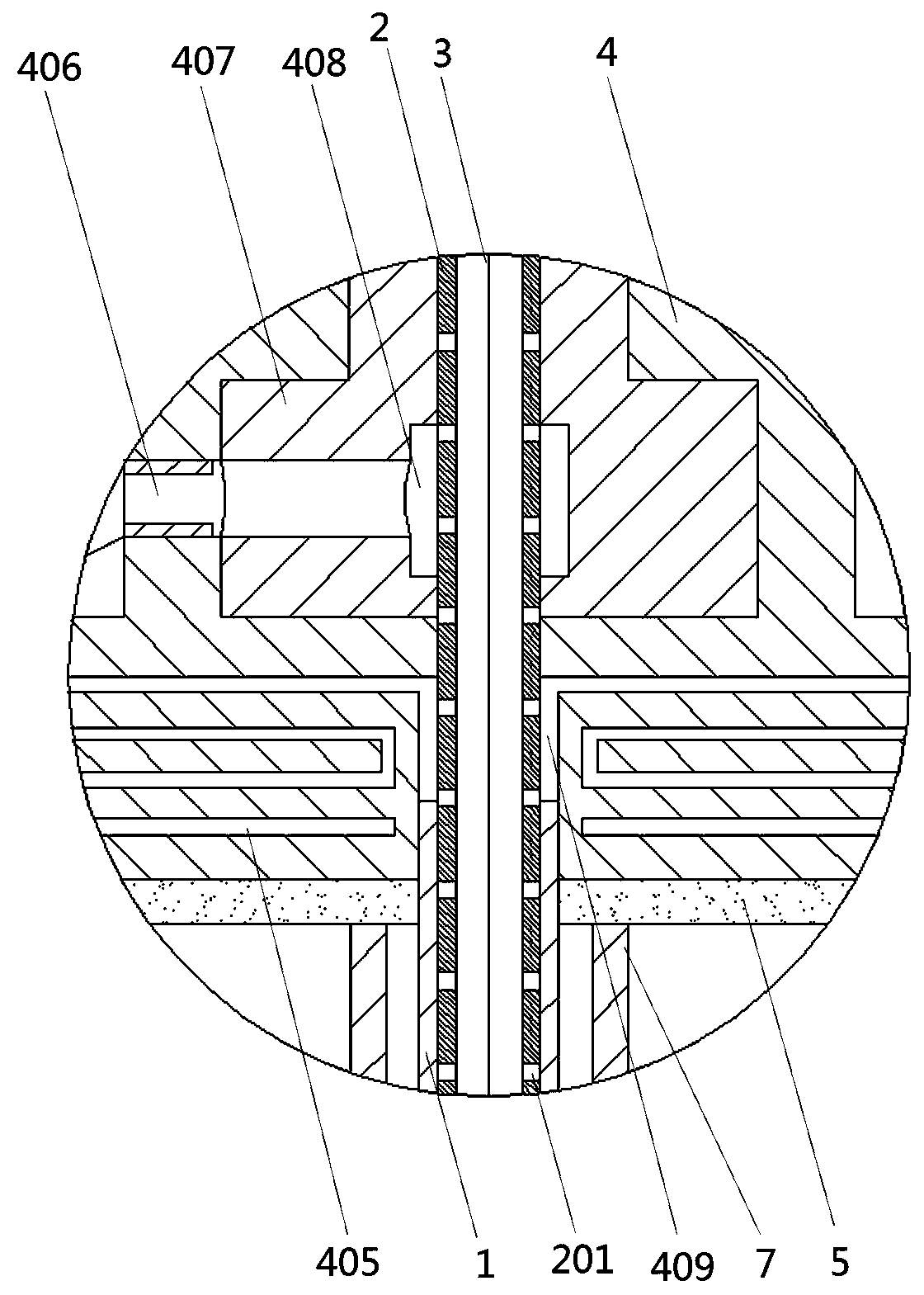

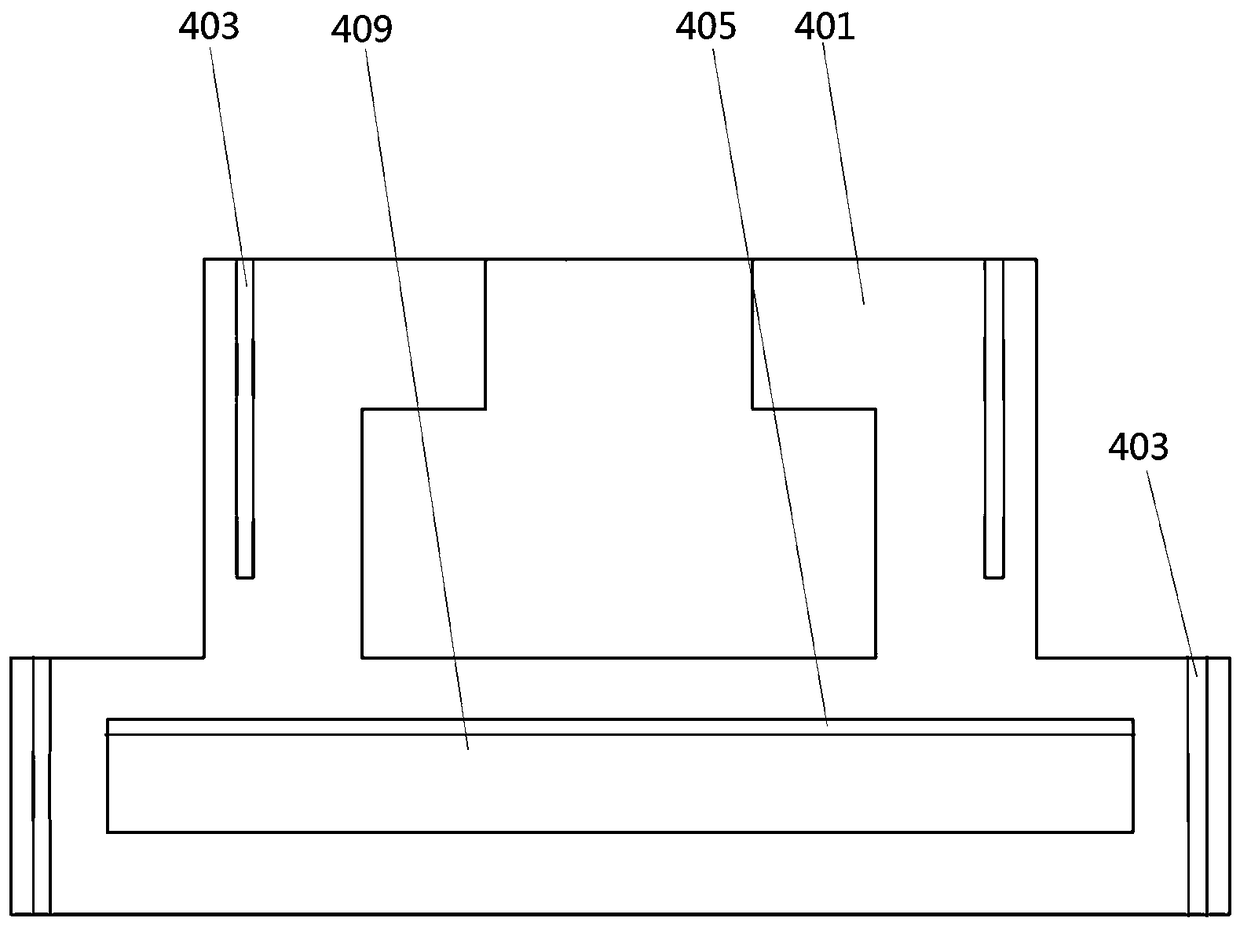

[0033] Embodiment 3, a lumbar puncture needle assembly with positioning and color development functions, the color development groove 405 is a return-shaped groove, and the end of the color development groove 405 that communicates with the vertical through hole is provided with a flared groove 409, and the flared groove 409 is greater than the height difference between two adjacent through holes 201 . The color developing tank is set as a circular groove, which is more convenient to observe the color developing reaction.

[0034] The other structures of this embodiment are the same as those of the second embodiment.

Embodiment 4

[0035] Embodiment 4, a lumbar puncture needle assembly with positioning and color rendering functions, the rotary switch is a cylindrical casing sleeved on the outside of the drainage top seat, the side wall of the cylindrical casing is sealed with the communication port 406, and the cylindrical casing is The side wall of the casing is provided with a liquid outlet that is movably matched with the communication port, and the liquid outlet is connected to the syringe through a hose. The rotary switch is arranged on the outer side of the drainage top seat, and the structure is simple and convenient for production. It is not necessary to set the positioning seat 4 as a combined structure, and it can be integrally formed.

[0036] The other structures of this embodiment are the same as those of the third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com