Method for preparing photocatalytic adsorption material from high-titanium blast furnace slag

A technology of high-titanium blast furnace slag and adsorption materials, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. High cost and other issues, to achieve the effect of simple preparation process, improved resource utilization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

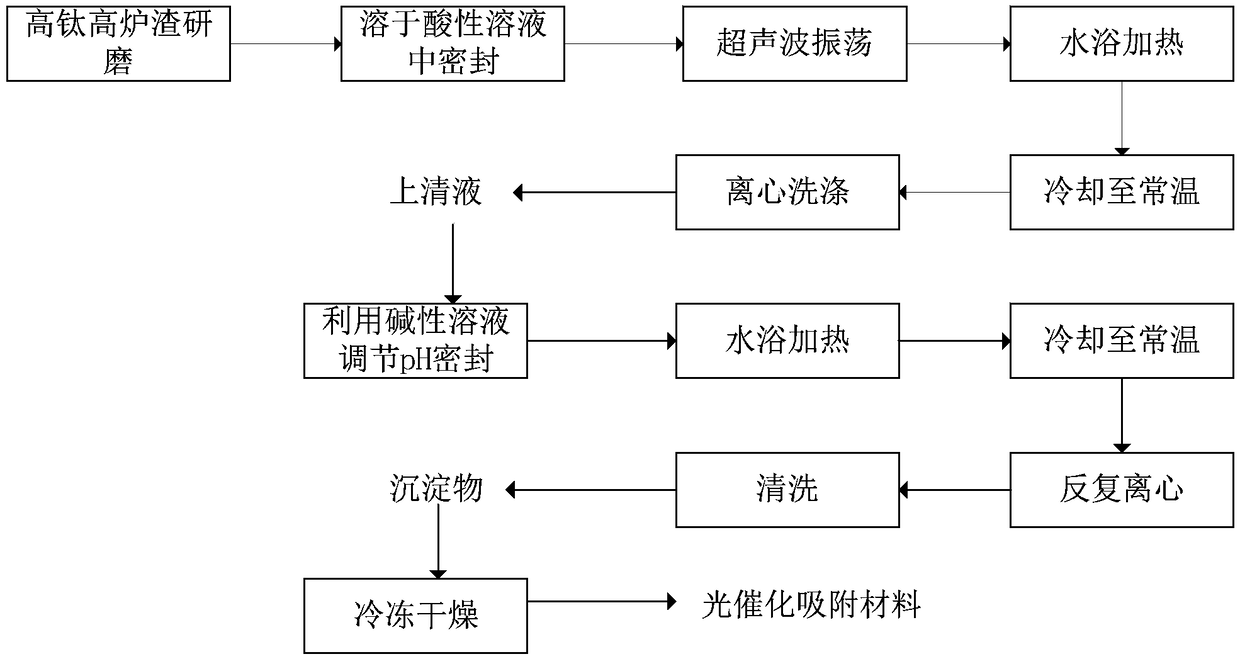

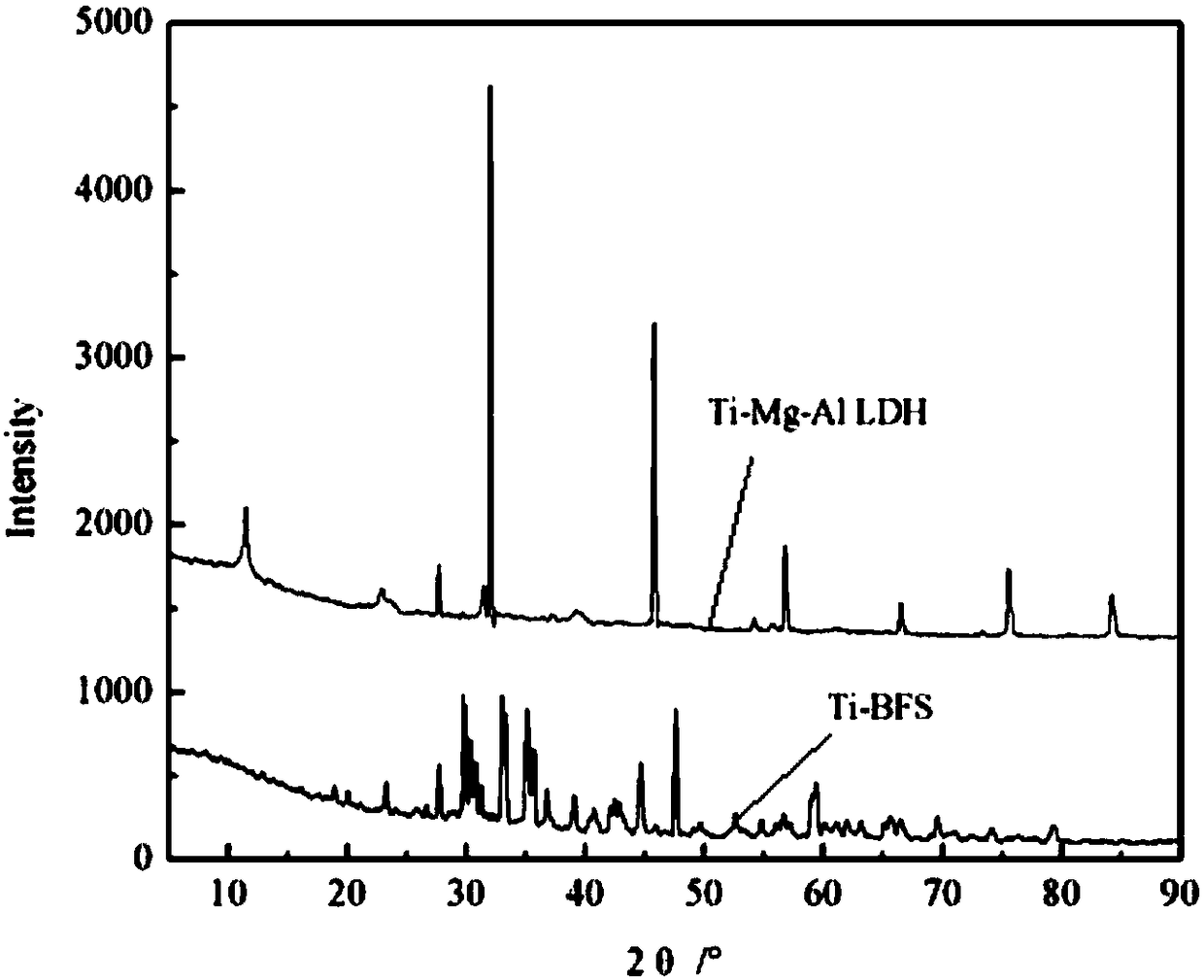

[0036] A method for preparing a photocatalytic adsorption material by using high-titanium blast furnace slag, the preparation method and application steps are as follows:

[0037] Grind the high-titanium blast furnace slag to 30-60um; then weigh 10g of high-titanium blast furnace slag fine powder and dissolve it in 200ml hydrochloric acid solution, the concentration of hydrochloric acid solution is 2mol / l, seal it with a sealing film and vibrate ultrasonically for 20min; then put it in a constant temperature water bath Heated in a water bath at 95°C for 12 hours; cooled to room temperature, centrifuged and washed with ultrapure water for 3 times, then centrifuged to collect the supernatant, and the supernatant was adjusted to pH 11.5 with 5mol / l NaOH solution; then sealed with a parafilm at 70 Heating in a water bath at ℃ for 16 hours; cooling to room temperature and then centrifuging, washing with ultrapure water for 3 times, centrifuging again to obtain a precipitate, and fin...

Embodiment 2

[0039] A method for preparing a photocatalytic adsorption material by using high-titanium blast furnace slag, the preparation method and application steps are as follows:

[0040] Grind the high-titanium blast furnace slag to 30-60um; then weigh 10g of high-titanium blast furnace slag fine powder and dissolve it in 200ml hydrochloric acid solution, the concentration of the hydrochloric acid solution is 3mol / l, seal it with a sealing film and vibrate ultrasonically for 20min; then put it in a constant temperature water bath Heated in a water bath at 90°C for 24 hours; after cooling to room temperature, centrifuged and washed with ultrapure water for 3 times, then collected the supernatant by centrifugation, and adjusted the pH of the filtrate to 10.5 with 10mol / l NaOH solution; Heating in a water bath at ℃ for 24 hours; cooling to room temperature and then centrifuging, washing with ultrapure water for 3 times, centrifuging again to obtain a precipitate, and finally freeze-dryin...

Embodiment 3

[0042] A method for preparing a photocatalytic adsorption material by using high-titanium blast furnace slag, the preparation method and application steps are as follows:

[0043]Grind the high-titanium blast furnace slag to 30-60um; then weigh 10g of high-titanium blast furnace slag fine powder and dissolve it in 200ml of hydrochloric acid solution, the concentration of the hydrochloric acid solution is 5mol / l, seal it with a sealing film and vibrate ultrasonically for 20min; then put it in a constant temperature water bath Heated in a water bath at 95°C for 18 hours; after cooling to room temperature, centrifuged and washed with ultrapure water for 3 times, then collected the supernatant by centrifugation, and adjusted the pH of the filtrate to 11.0 with 2mol / l NaOH solution; Heating in a water bath at ℃ for 18 hours; cooling to room temperature and then centrifuging, washing with ultrapure water for 3 times, centrifuging again to obtain a precipitate, and finally freeze-dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com