A kind of preparation method of olefin epoxidation catalyst of polyaniline supported heteropolyacid

A technology for supporting heteropolyacids and catalysts, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc. It can solve the problem of large loss of non-supported catalysts and difficulty in industrialization , complex preparation process and other issues, to achieve good catalytic epoxidation effect, easy to scale up and industrialize, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

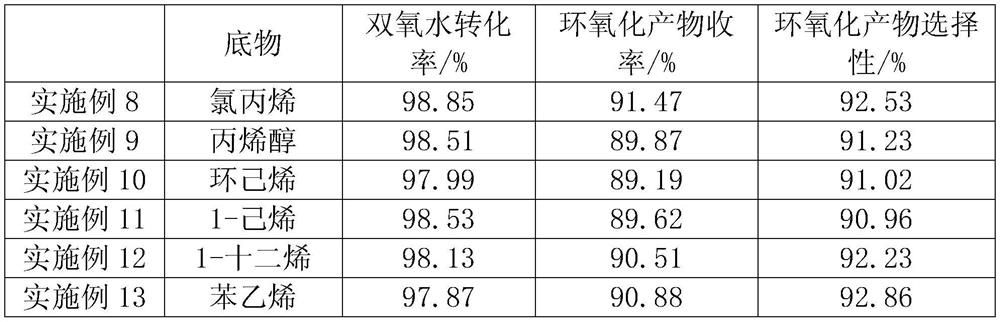

Examples

Embodiment 1

[0024] Catalyst preparation: at room temperature, dissolve 13.24g of sodium tungstate dihydrate (0.04mol) in 20g of water, and add 9.22g of 85% phosphoric acid (0.08mol), 31.56g of 30% H 2 o 2 solution (0.28mol), the resulting clear solution is solution A; slowly add 26.48g aniline (0.28mol) dropwise to 111.45g 25% phosphoric acid solution (0.28mol), and the resulting clear solution is solution B.

[0025] Under ice bath, slowly add solution A dropwise to solution B, control the temperature of the kettle at 5-10°C, stir vigorously for 24 hours, filter, wash the filter cake with water until the washing liquid is neutral, dry the filter cake under vacuum at 60°C for 6 hours, and obtain 28.18g of catalyst , tungsten content 22.31%, load rate 85.16%, marked as PW-PAn.

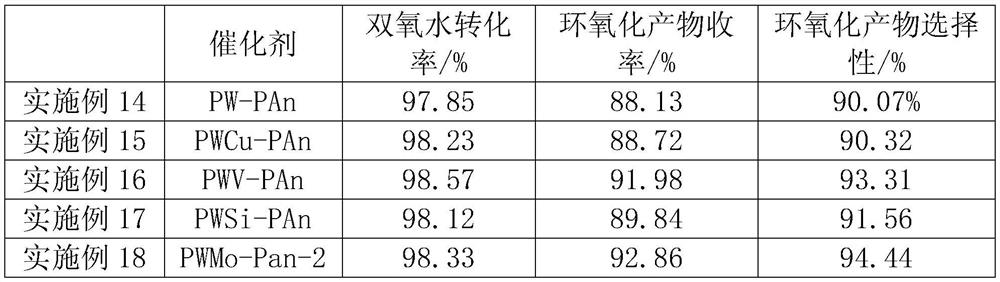

Embodiment 2-5

[0027] Catalyst preparation: the preparation process is the same as in Example 1, only 0.01mol of different salts are added before the hydrogen peroxide is added dropwise, and the obtained results are as follows:

[0028] metal salt Tungsten loading rate / % Catalyst code Example 2 copper nitrate 84.64 PWCu-PAn Example 3 Sodium vanadate 84.31 PWV-PAn Example 4 Sodium silicate 83.51 PWSi-PAn Example 5 Sodium molybdate 86.21 PWMo-PAn

Embodiment 6

[0030] Catalyst preparation: The preparation process is the same as in Example 5, except that 4.12 g of sodium molybdate (0.02 mol) is added before the hydrogen peroxide is added dropwise, and the tungsten loading rate of the obtained catalyst is 86.25%, which is marked as PWMo-PAn-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com