Feeding mine box of magnetic separator

A technology of magnetic separator and ore box, applied in conveyors, magnetic separation, solid separation, etc., can solve the problems of early discharge of waste, insufficient dispersion of feeding materials, poor separation quality, etc. , The effect of reducing magnetic agglomeration and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

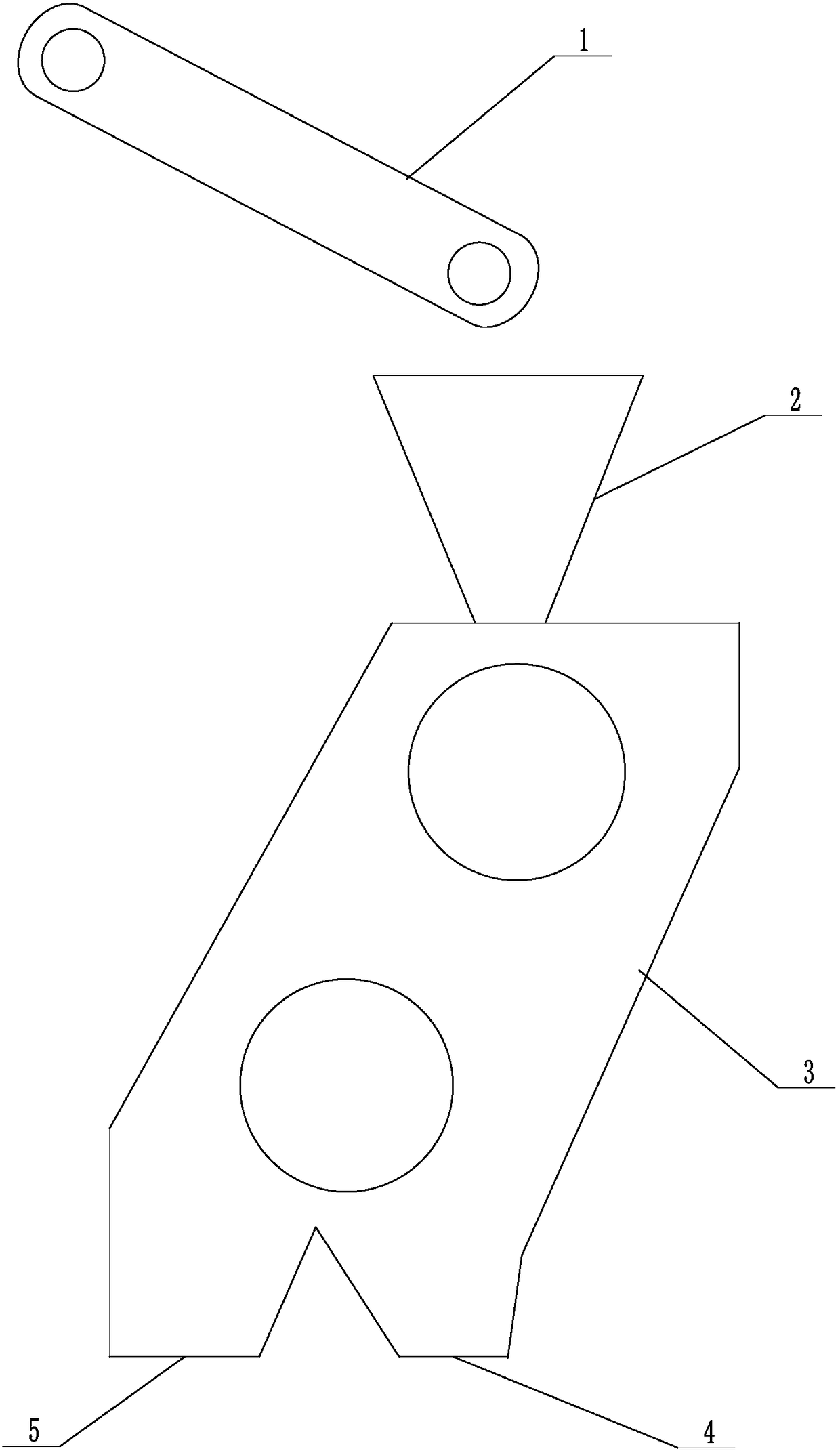

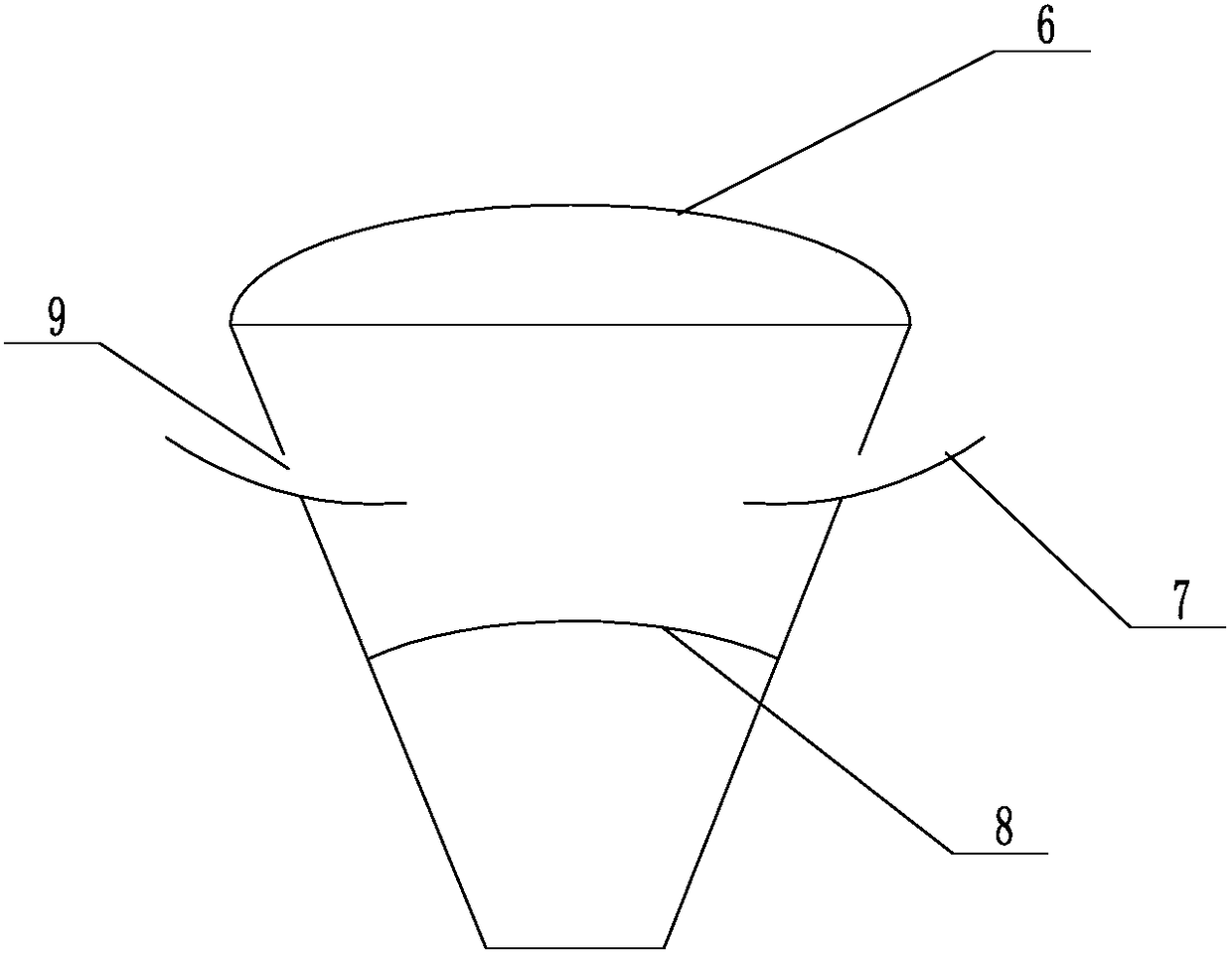

[0018] Such as Figure 1-2 As shown, the magnetic separator feeding ore box of the present invention includes a box body 2, an external arc-shaped filter screen 6 is arranged on the top of the box body 2, and a receiving plate 7 is arranged in the middle of the box body 2, and the receiving plate 7 is an arc shape, surrounds the box body 2, one end of the receiving plate 7 is located outside the box body 2, and the other end is located inside the box body 2, the whole is in the shape of an inclined arc, and the upper part of the connection between the receiving plate 7 and the box body 2 is open. There is a feed port 9, and the feed port 9 is set at a certain distance, which can properly block the material with large particles outside the box body 2, and manually remove the waste materials. The inside of the box body 2 is equipped with a built-in curved filter 8. The built-in curved filter screen 8 is located at the lower end of the receiving plate 7, and both the external cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com