Finishing machining device and method in pneumatic suspension abrasive tank

A finishing process and abrasive technology, applied in grinding/polishing safety devices, grinding workpiece supports, metal processing equipment, etc., can solve the problems of different removal rules, high cost and short life of magnetic abrasives, and achieve easy replacement of abrasives , high finishing efficiency, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

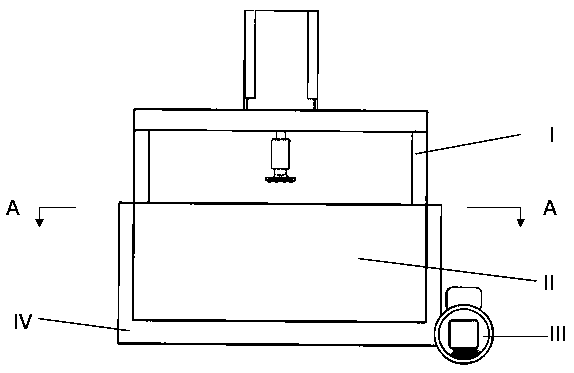

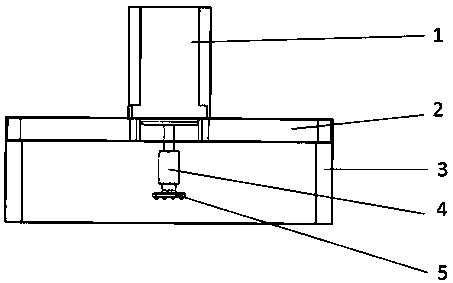

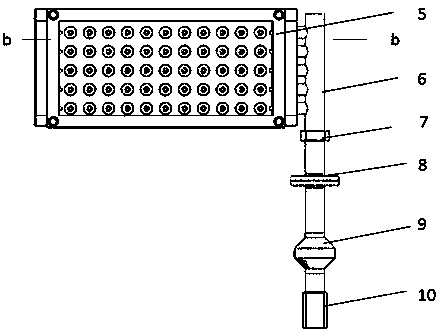

[0012] combine figure 1 , figure 2 , image 3 , Figure 4 Describe in detail an air-suspended abrasive pool finishing device, characterized in that:

[0013] The device includes workpiece rotary feeding system-I, abrasive pool-II, wind power feeding system-III, and base-IV; the workpiece rotary system-I mainly includes: stepping motor [1], support plate [3 ], upper cover plate [2], coupling [4], magnetic workpiece fixture [5]; said abrasive pool-II and wind feed system-III mainly include: adjustable wind power generating device [10], air filter , Cooling device [9], Flange and sealing ring [8], Conduit [6], Nozzle and internal filter screen [12], Air pressure detection device [7], Bottom air hole [11], Side air hole [13] , Abrasive Pool-Ⅱ.

[0014] The adjustable wind generating device [10] of the device is connected with the air filter and the cooling device [9], and the air filter device [9] is connected with the conduit [6] through the flange plate and the sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com