A Method for Fabricating Nanoscale Electrofluidic Nozzles Using Structure-Inducing Method

A nanoscale, structure-induced technology, applied in nanotechnology, coating devices, additive processing, etc., can solve the problems of complex process and high cost of nanoscale electric jet needles, and achieve simple preparation process, low cost, and convenient The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

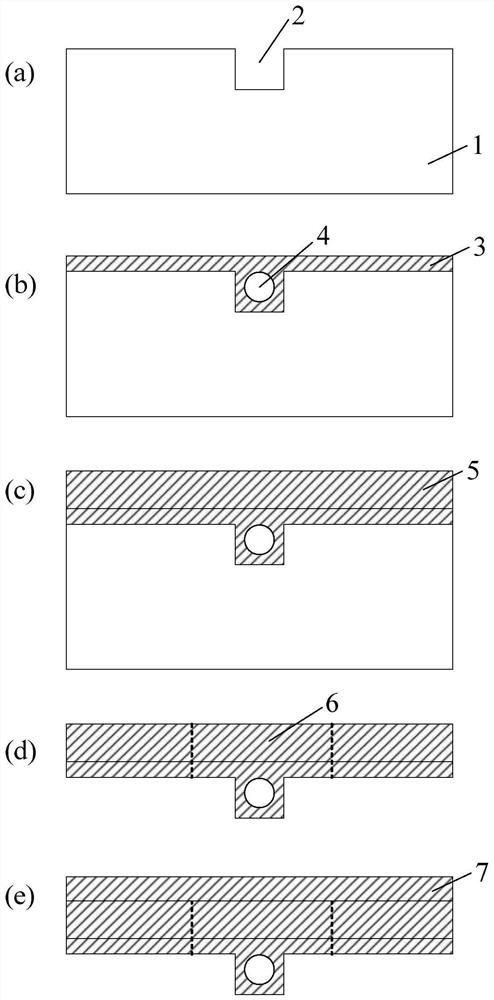

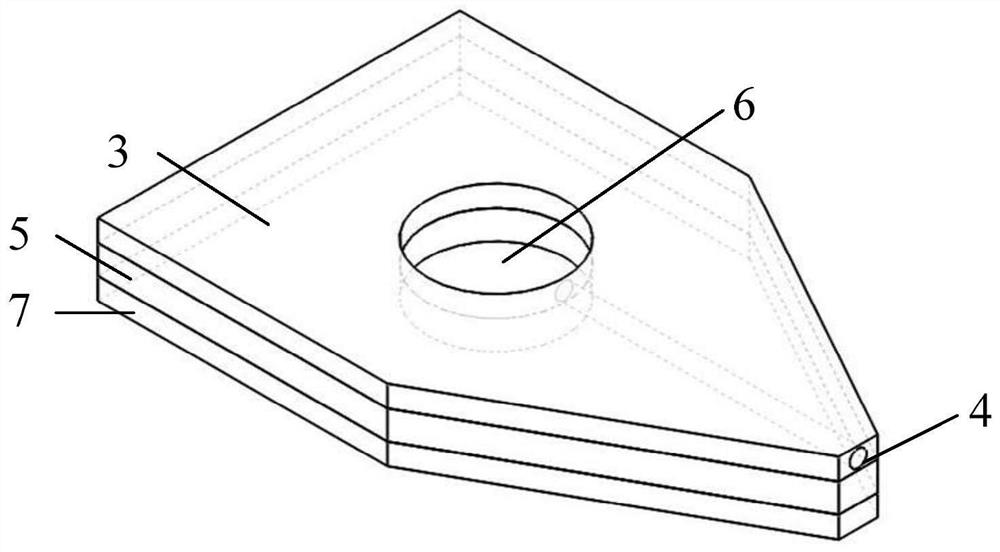

[0017] The specific implementation manner of the patent of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0018] 1. Fabrication of PMMA substrates with nanoscale electrofluidic needle-induced patterns

[0019] (1) Cut out a PMMA plastic substrate 1 of 4×5 cm by laser cutting. After washing and drying, such as figure 1 As shown in a, nano-channels with a width and depth of about 500 nanometers are imprinted on it by hot pressing, and the nozzle nanostructure-induced pattern 2 is produced. The parameters of the hot pressing are: the hot pressing temperature is 150-200 degrees centigrade, the hot pressing pressure is 1.5-2 MPa, and the hot-pressing time is 15-20 minutes.

[0020] (2) Put the PMMA substrate with the nanostructure induced pattern after hot pressing in the drying tower. Put trimethylchlorosilane inside the drying tower and evaporate for 5 to 10 minutes, so that the PMMA substrate with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com