A hanging structure for seat foam

A foam and seat technology, which is applied in vehicle seats, chairs, applications, etc., can solve the problems of poor bonding force between the suspending wire and the foam, complex foam modeling, restricted modeling and skeleton layout, etc. Achieve the effect of solving the problem of wire drawing force, reducing the number of magnets for positioning, and saving production management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

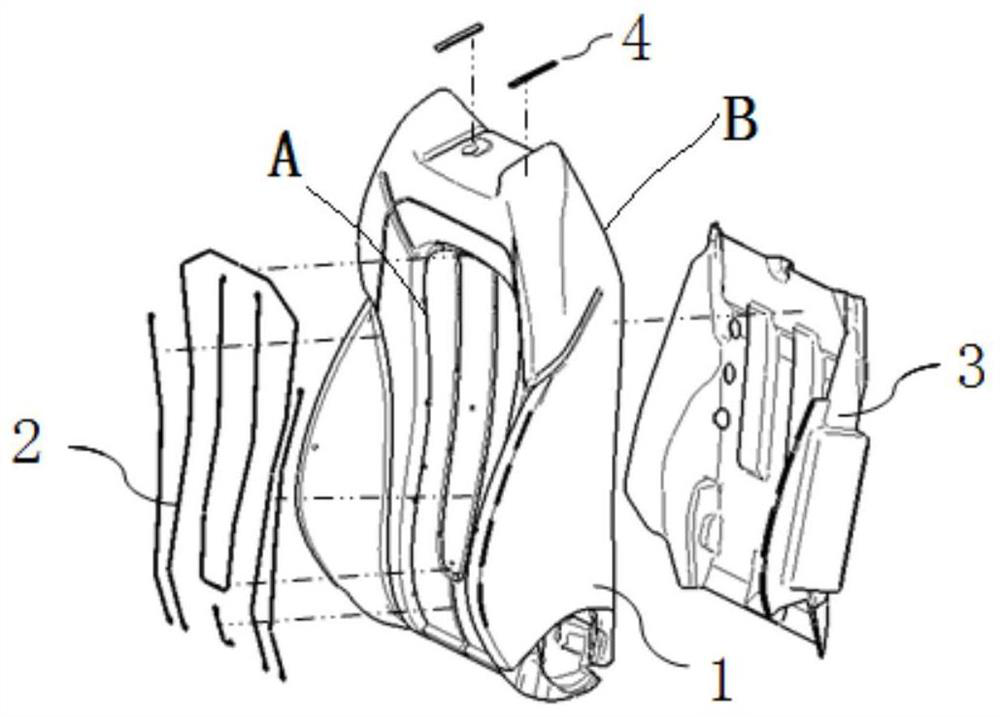

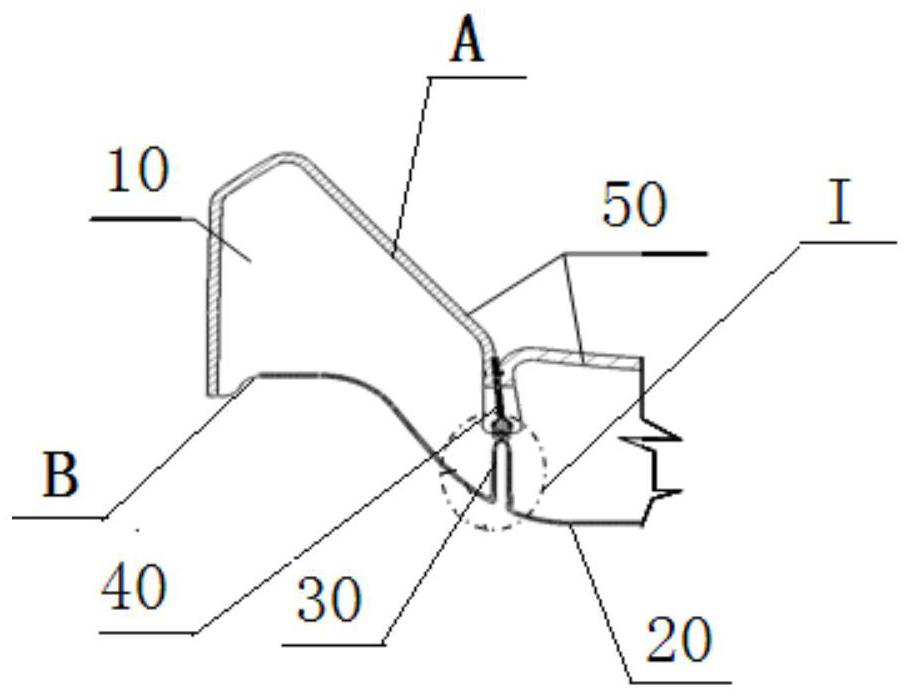

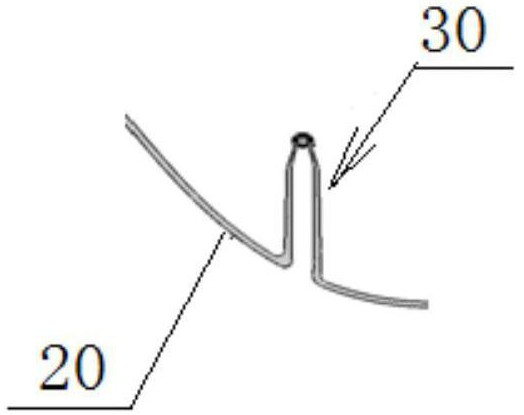

[0107] see figure 2 and image 3 , a suspending structure for seat foam shown in the figure, including foam 10 and reinforcing cloth 20. The suspending structure 30 is directly arranged on the side B of the reinforcing cloth 20 facing the foam body 10 and corresponds to the fixing point of the surface cover 50 . The suspending structure 30 tightens the surface covering 50 located on the surface A of the foamed body 10 through the surface covering tensioning structure 40.

[0108] see Figure 4 In the foaming process of the seat cushion of the traditional scheme, the cushion steel wire 2a is on the A side of the seat cushion foam body 1a, the seat cushion reinforcement cloth 3a is on the B side of the seat cushion foam body 1a, and the cushion steel wire 2a and the seat cushion reinforcement cloth 3a are independent of each other. In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com