Composite piezoelectric substrate and preparation method thereof

A piezoelectric and substrate technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., to solve problems affecting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

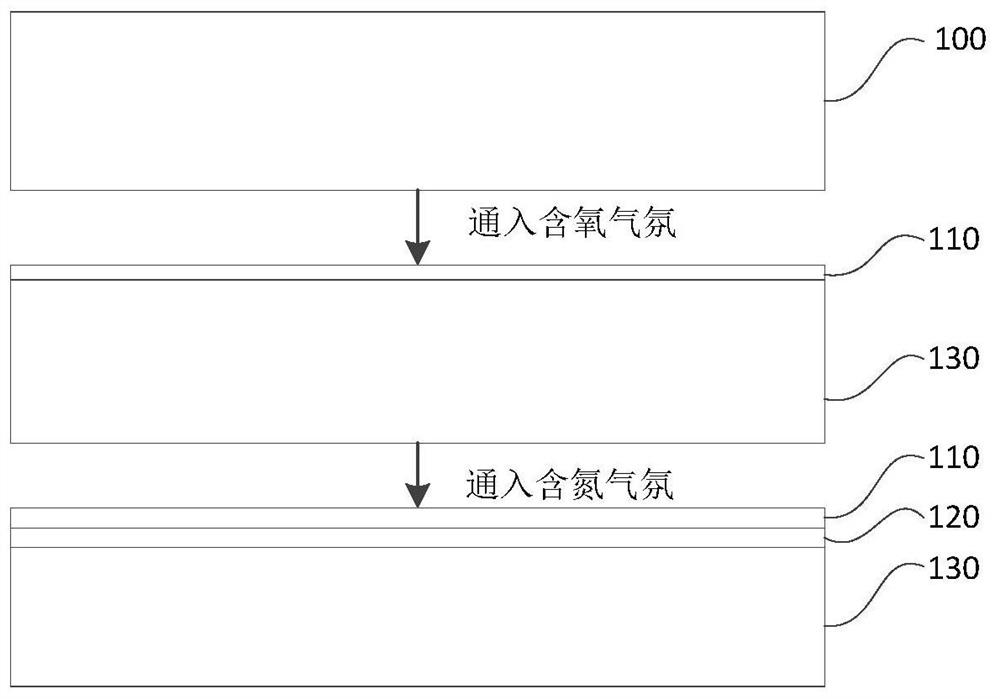

[0033] In order to solve the problem in the prior art that when the composite piezoelectric substrate is prepared by the deposition method, the deposition chamber needs to be frequently switched and the production efficiency is affected, the present application provides a method for preparing a composite piezoelectric substrate, which includes the following steps:

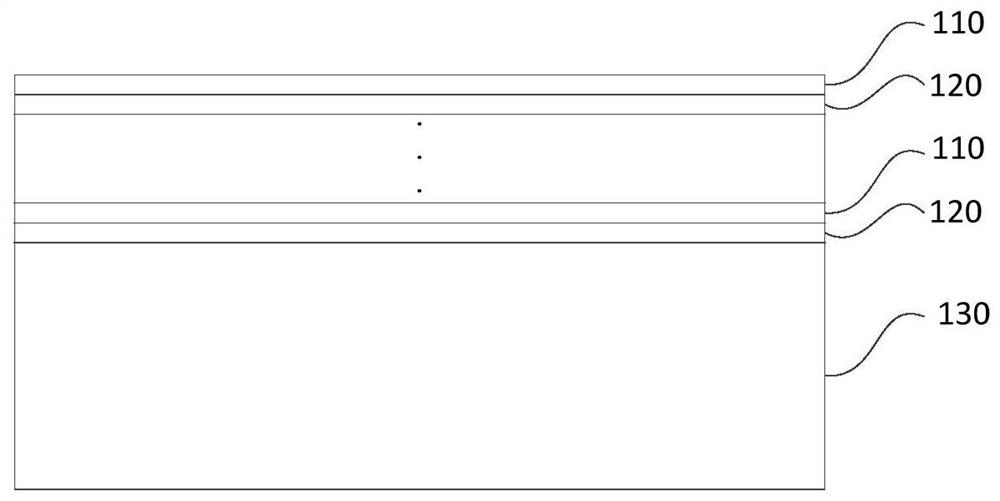

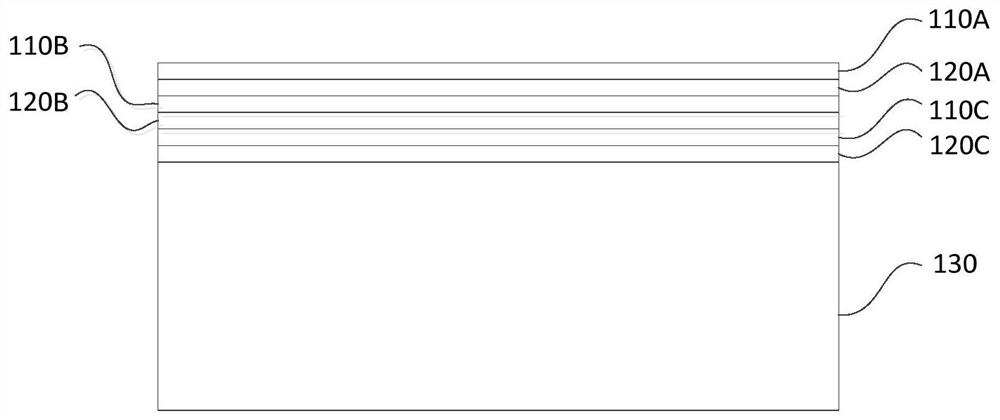

[0034] Put the silicon wafer into the reaction furnace, alternately circulate the first reaction atmosphere and the second reaction atmosphere into the reaction furnace until the target composite piezoelectric substrate is prepared, and the target composite piezoelectric substrate is included in the In the silicon wafer, the first substrate layer and the second substrate layer are alternately stacked from the outer surface of the silicon wafer inward, wherein the first reaction atmosphere is an oxygen-containing atmosphere or a nitrogen-containing atmosphere, and the second The reaction atmosphere is an oxygen-conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com