Magnetic hot melt type sulphide mastic as well as preparation method and application thereof

A technology of sulfur mastic and magnetic heat, which is applied in excavation, construction, infrastructure engineering, etc., can solve the problems of increasing the difficulty and cost of underground obstacles, the impact of underground environment, and obstacles to the construction of surrounding buildings, so as to reduce the difficulty of construction, Easy dismantling and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of above-mentioned magnetothermal melting type sulfur mastic comprises the following steps:

[0021] Step 1: Weigh according to the following composition ratio: 60-70 parts of sulfur, 35-40 parts of corrosion-resistant filler, 5-10 parts of magnetic powder, 5-10 parts of toughening agent, 3-5 parts of hyperdispersant and mineral doping 2 to 4 parts of ingredients;

[0022] Step 2: Pour the sulfur into the iron pot first, heat it to 135-150°C and keep it for 30 minutes to melt it;

[0023] Step 3: Add other materials into the molten sulfur and heat it to above 170°C. Stir continuously during the process to ensure that all components are fully combined to obtain sulfur cement with magnetothermal melting effect;

[0024] Step 4: Finally, when the magnetic hot-melt sulfur mortar is poured at about 140°C, there should be no bubbles in the "8"-shaped test block, and it should be interrupted from the middle to observe that there are less than 5 small ho...

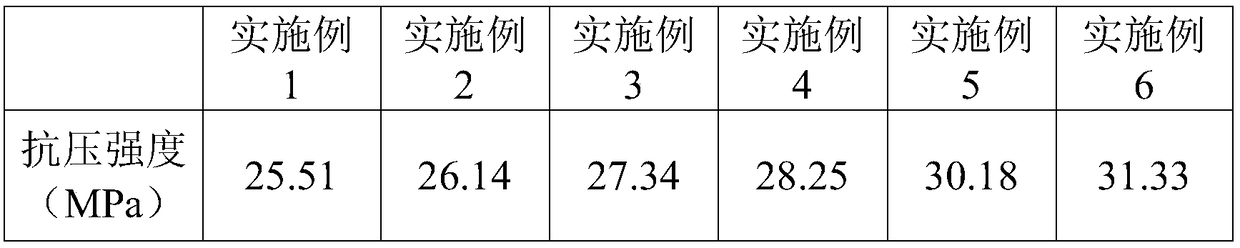

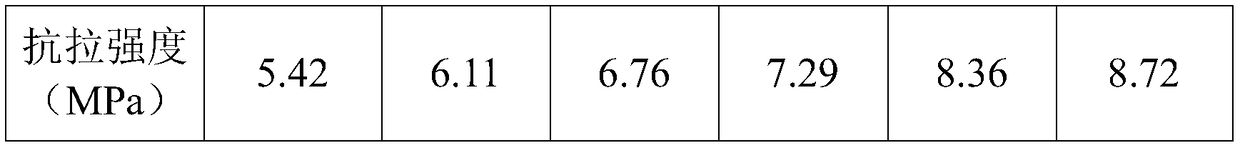

Embodiment 1

[0028] 60 parts of sulfur, 35 parts of corrosion-resistant filler, 5 parts of magnetic powder, 5 parts of toughening agent, 3 parts of hyperdispersant, 2 parts of mineral admixture, the density of the above components after mixing is 2343kg / m 3 .

[0029] Among them, the corrosion-resistant filler is quartz powder. The magnetic powder is manganese zinc ferrite powder, and the toughening agent is polyvinyl chloride. The hyperdispersant is acrylate and the mineral admixture is silica fume.

Embodiment 2

[0031] 62 parts of sulfur, 36 parts of corrosion-resistant filler, 6 parts of magnetic powder, 6 parts of toughening agent, 3 parts of hyperdispersant, 2 parts of mineral admixture, the density of the above components after mixing is 2417kg / m 3 .

[0032] Among them, the corrosion-resistant filler is quartz powder. The magnetic powder is manganese zinc ferrite powder, and the toughening agent is polyvinyl chloride. The hyperdispersant is acrylate and the mineral admixture is silica fume.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com