Reinforcement method for pulp molding product with PLA

A technology of pulp molding and molded products, which is applied in the direction of non-fiber pulp addition, synthetic cellulose/non-cellulose material pulp/paper, paper, etc., which can solve the problems of insufficient product stiffness, low surface strength, lint and powder loss and other problems to achieve the effect of improving the appearance, increasing the tensile strength, and improving the stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

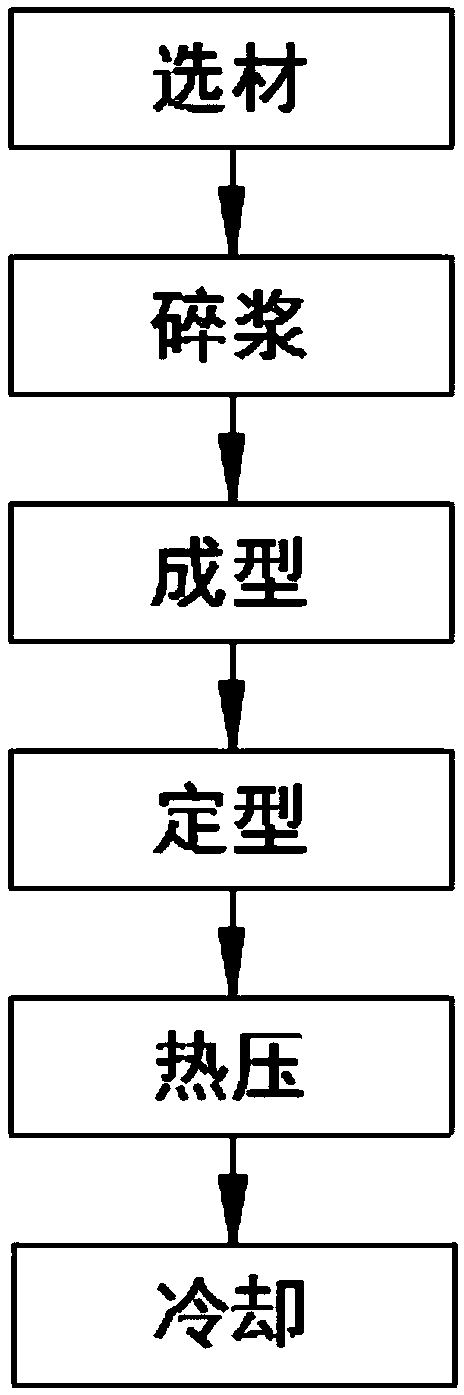

[0028] The present invention provides such figure 1 A kind of pulp molded article reinforcing method of adding PLA shown, described specific steps are as follows:

[0029] Step 1: Material selection, choose the raw material of molded products, the raw material is wood pulp or bamboo pulp, choose PLA fiber similar to the shape of papermaking fiber, the fiber length is 1-5mm, and the melting point is about 170 ℃, which can ensure the production process of pulp molded products Among them, PLA can be well retained, select cellulose, and the cellulose is one or more of polyvinyl alcohol, carboxymethyl cellulose, hydroxypropyl methyl cellulose and cellulose ether;

[0030] Step 2: pulping, pulping and dispersing the PLA fiber, cellulose and molding product raw materials together, and then refining it through a refiner to make a slurry that can be used for molding production. The cellulose is dissolved in water to form a viscous solution. The mucilage sticks the PLA fiber and the ra...

Embodiment 2

[0038] Different from Example 1, step 6 can also produce pulp molded products first according to the normal process requirements, and then add an additional hot-melt step, that is, put the pulp molded products into the hot pressing mold again, and heat to 170- Take it out after 180°C and maintain it for 10-20 seconds to achieve the purpose of melting and re-solidifying the PLA.

Embodiment 3

[0041] The present invention provides such figure 1 A kind of pulp molded article reinforcing method of adding PLA shown, described specific steps are as follows:

[0042] Step 1: Material selection, choose the raw material of molded products, the raw material is wood pulp or bamboo pulp, choose PLA fiber similar to the shape of papermaking fiber, the fiber length is 1-5mm, and the melting point is about 170 ℃, which can ensure the production process of pulp molded products Among them, PLA can be well retained, select cellulose, and the cellulose is one or more of polyvinyl alcohol, carboxymethyl cellulose, hydroxypropyl methyl cellulose and cellulose ether;

[0043]Step 2: pulping, pulping and dispersing the PLA fiber, cellulose and molding product raw materials together, and then refining it through a refiner to make a slurry that can be used for molding production. The cellulose is dissolved in water to form a viscous solution. The mucilage sticks the PLA fiber and the raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com