Control system and method for inhibiting stick-slip vibration of drilling string based on frequency converter auxiliary feeding set rotating speed

A technology with a given rotational speed and stick-slip vibration, which is applied in the automatic control system of drilling, drilling equipment, earth-moving drilling, etc. Achieve the effect of suppressing stick-slip vibration of drill string, suppressing stick-slip vibration, and systematic science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

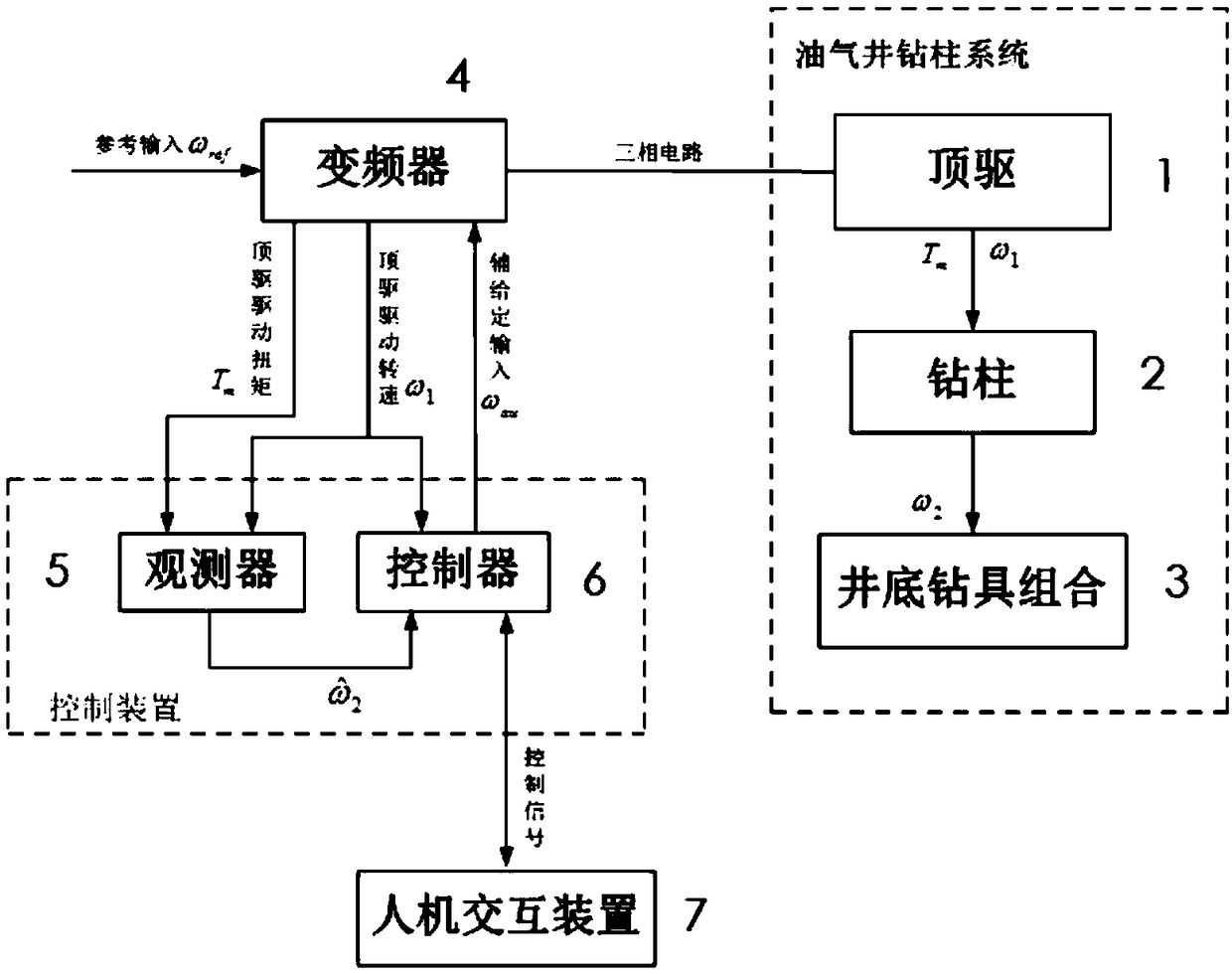

[0047] Such as figure 1 As shown, the control system for suppressing stick-slip vibration of the drill string based on the auxiliary given speed of the frequency converter mainly includes: the oil and gas well drill string system (controlled object), frequency converter, control device and human-computer interaction device. in:

[0048]Oil and gas well drilling string system mainly includes top drive 1, drill string 2 and bottom hole assembly 3, used to realize the drilling of oil and gas wells; among them, top drive 1 mainly includes motor, reducer and rotary table, used for Oil and gas well drill string systems provide driving torque. Among them, the drill string 2 can reach several kilometers, and is formed by connecting many drill pipes, and is used for transmitting torque for the bottom hole assembly 3 and providing a transportation chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com