Analysis method and system for identifying heat treatment degree and doping of liquid milk

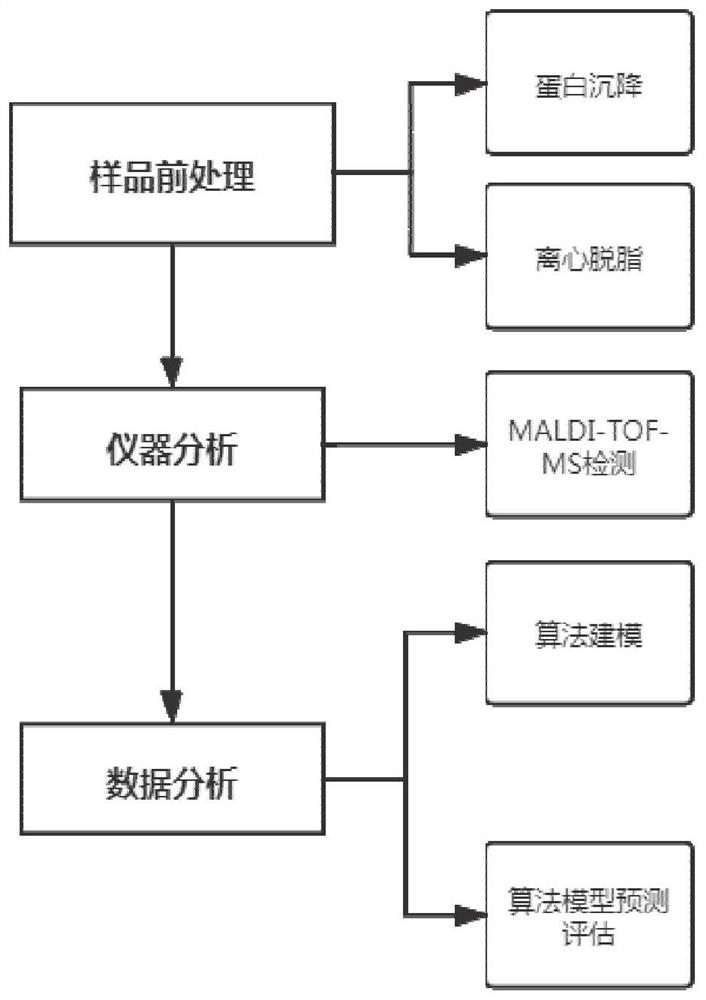

An analysis method and technology for liquid milk, applied in the direction of analyzing materials, material analysis by electromagnetic means, character and pattern recognition, etc., can solve the problems of sterilization conditions cannot be verified, and cold chain technology cannot be tracked in the whole process, reaching Qualcomm The effect of high volume, simple operation and accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Select enough commercially available pasteurized milk, extended shelf-life pasteurized milk, and ultra-high temperature sterilized milk, and measure the corresponding volume of milk respectively, and take 30ml for each type of milk;

[0058] 2. Centrifuge each milk sample at 4°C and 1100×g (2×1h), remove the upper fat layer, and perform the degreasing process;

[0059] 3. Take 1ml of skim milk samples with different heating degrees, each sample is paralleled 20 times, add 3ml of acetonitrile solution respectively, carry out organic solvent precipitation protein, let it stand for half an hour, and take the supernatant;

[0060] 4. Mix 5 μl supernatant sample with 5 μl saturated CHCA matrix solution for each parallel, and place it for testing;

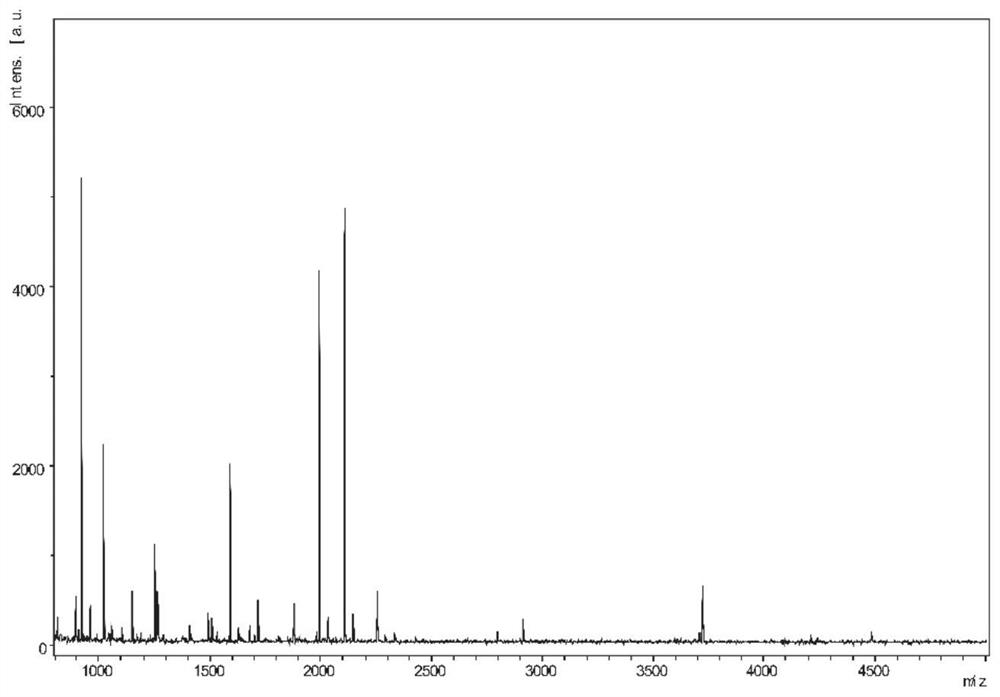

[0061] 5. Take 1 μl of the mixed sample to be tested, spot the sample on the target plate, and let it dry naturally. After drying and crystallization, put it into the MALDI-TOF-MS instrument for scanning and detection, and obta...

Embodiment 2

[0071] 1. Select enough commercially available pasteurized milk and ultra-high temperature sterilized milk, according to the volume ratio (pasteurized milk: ultra-high temperature sterilized milk) 1:1, 2:1, 3:1, 4:1, 5:1 , respectively measure the corresponding volume of milk for mixing, the total volume is 30ml, vortex for 1 minute, and mix well;

[0072] 2. Centrifuge the mixed milk sample at 4°C and 1100×g (2×1h), remove the upper fat layer, and perform the degreasing process;

[0073] 3. Take 1ml of skim milk samples with different volume ratios, each sample is paralleled 20 times, add 3ml of acetonitrile solution respectively, carry out organic solvent precipitation protein, let it stand for half an hour, and take the supernatant;

[0074] 4. Mix 5 μl supernatant sample with 5 μl saturated CHCA matrix solution for each parallel, and place it for testing;

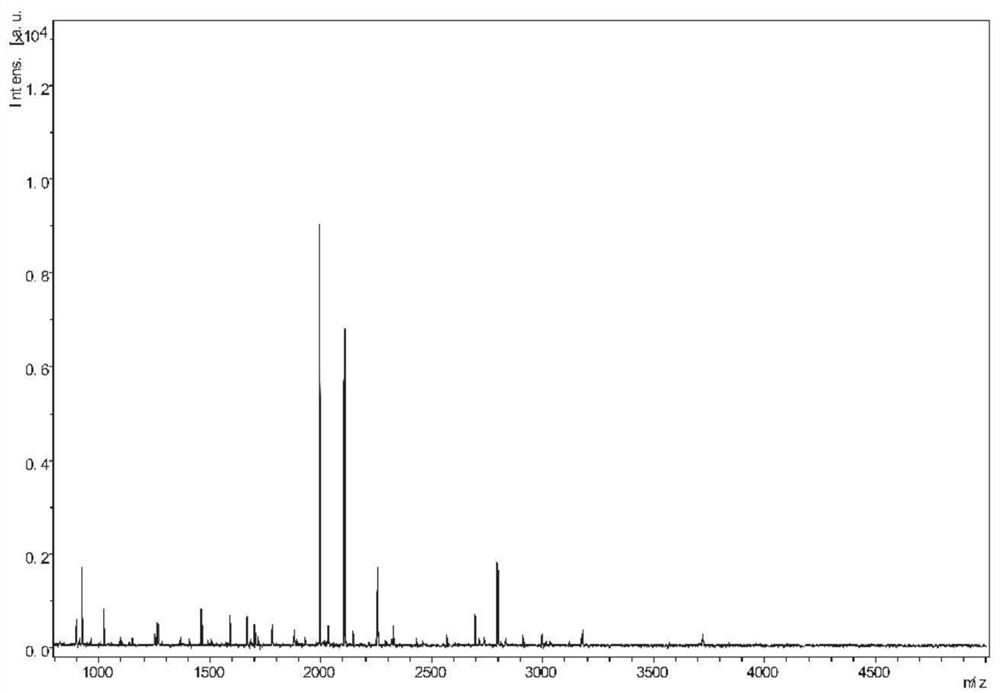

[0075] 5. Take 1 μl of the mixed sample to be tested, spot the sample on the target plate, and let it dry naturally....

Embodiment 3

[0085] 1. Select enough commercially available extended-shelf-life pasteurized milk and UHT milk, according to the volume ratio (extended shelf-life pasteurized milk: UHT milk) 1:1, 2:1, 3:1, 4 :1, 5:1, measure the corresponding volume of milk for mixing, the total volume is 30ml, vortex for 1 minute, and mix well;

[0086] 2. Centrifuge the mixed milk sample at 4°C and 1100×g (2×1h), remove the upper fat layer, and perform the degreasing process;

[0087] 3. Take 1ml of skim milk samples with different volume ratios, each sample is paralleled 20 times, add 3ml of pure acetonitrile solution respectively, carry out organic solvent precipitation protein, let it stand for half an hour, and take the supernatant;

[0088] 4. Take 5ul supernatant samples in parallel and mix them with 5μl saturated CHCA matrix solution, and place them for testing. After drying the crystals, put them into a MALDI-TOF-MS instrument for scanning detection to obtain the corresponding mass spectrum. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com