Active expansion type tube seam anchor rod, and preparation and use methods of active expansion type tube seam anchor rod

An expansion type, pipe seam technology, applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of unresolved pipe seam bolt installation difficulties, increased construction complexity, limited improvement of anchoring effect, etc., to achieve improved Anchor bolt installation speed and efficiency, ensuring anchoring effect, and overcoming the effect of anchoring force drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0054] This embodiment uses the active expansion type pipe seam bolt support of the present invention such as Figure 10 Shown is a roadway rock wall 18 in a metal mine. The surrounding rock of the roadway is feldspathic slate, and its joints and fissures 19 are relatively developed.

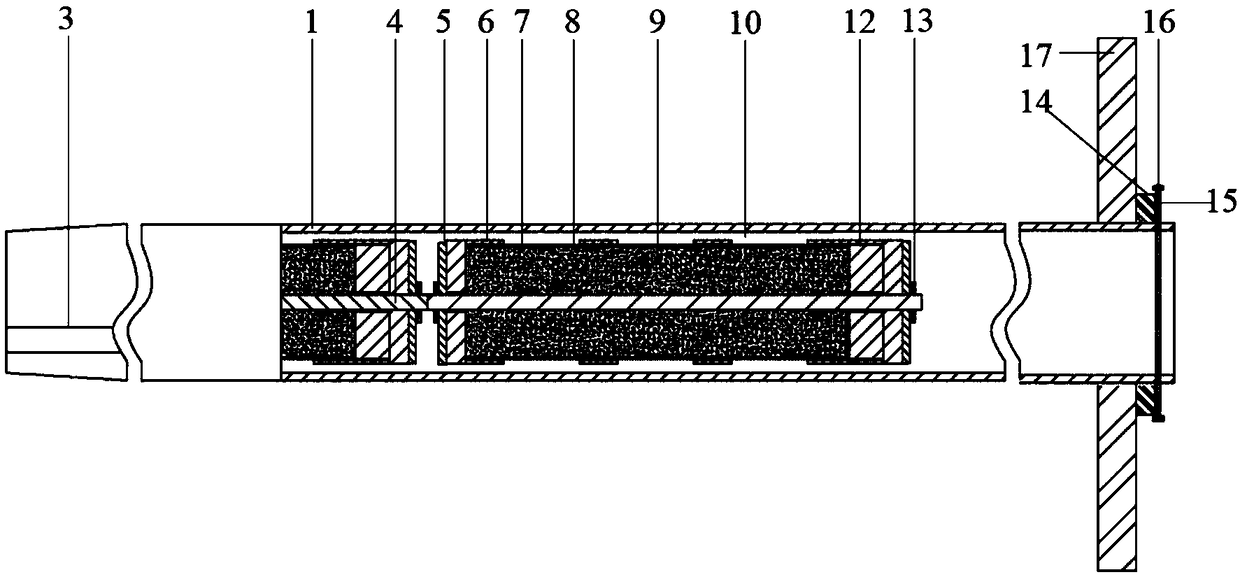

[0055] Such as figure 1 As shown, the active expansion type pipe anchor used in this embodiment includes a pipe seam anchor composed of a rod body 1 and a supporting device installed at the rear end of the rod body, and a self-expanding device placed in the pipe seam anchor body.

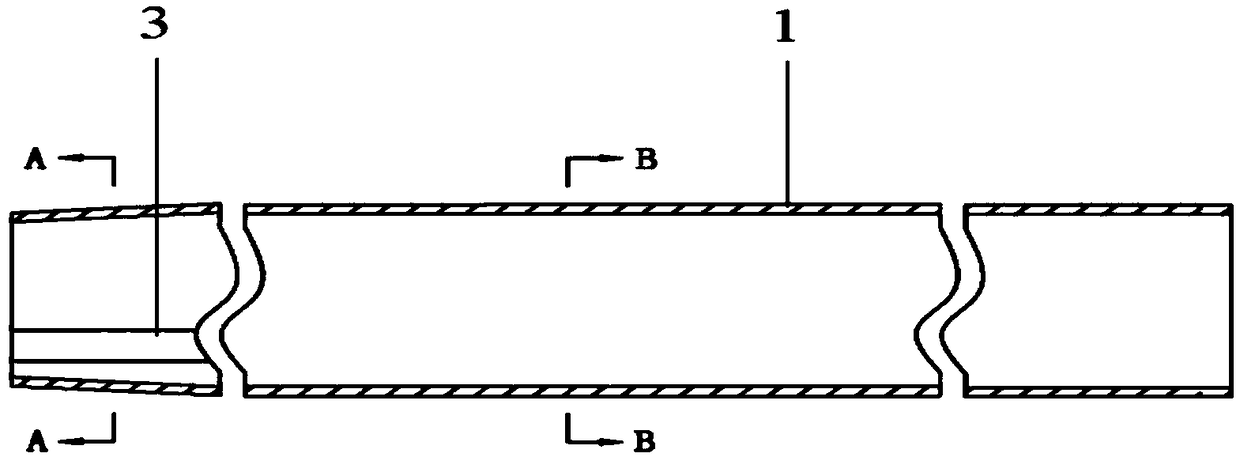

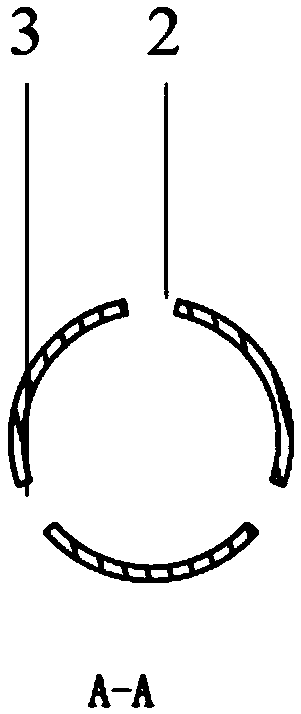

[0056] combine Figure 1 to Figure 4 , the rod body 1 is made of a steel pipe with a length of 1.8m, a thickness of 2mm, and a pipe seam 2 with a longitudinal width of 10mm. The outer diameter of the rear end of the rod body is 45mm, and the outer diameter of the front end is 42mm. Form lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com