Overspeed protection and flow control device for pumped storage power station

A technology of pumped storage power station and flow control device, which is applied in the directions of hydroelectric power generation, safety devices, engine components, etc., can solve the problems of long valve group response time, low mechanical adjustment accuracy, complicated system pipeline layout, etc., to achieve convenient The effect of observing and troubleshooting, high versatility and interchangeability, and simple electrical control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

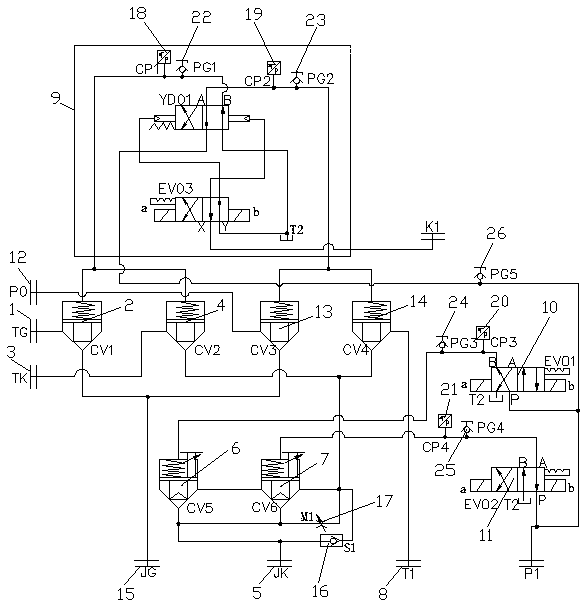

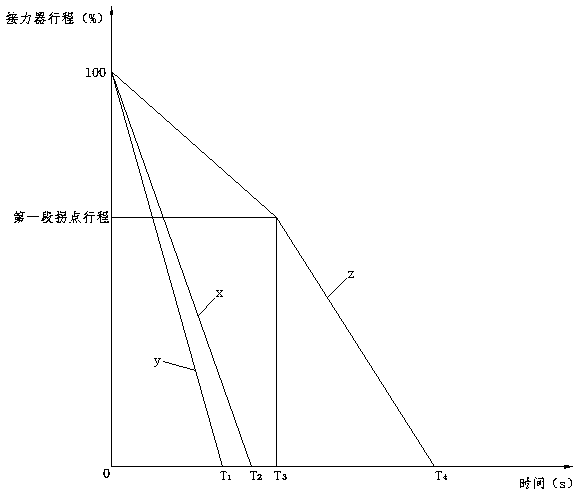

[0041] An overspeed protection and flow control device for a pumped storage power station, comprising a control pressure oil circuit, a first cartridge valve 2 connected to the closing chamber 1 of the main pressure distribution valve through the main oil circuit, and a first cartridge valve 2 connected to the main pressure distribution valve through the main oil circuit. The second cartridge valve 4 on the valve opening chamber 3, the first section closing cartridge valve 6 and the second section closing cartridge valve 7 connected to the servomotor opening chamber 5, also includes the oil return tank 8, the pilot type Electro-hydraulic reversing valve 9, first segment closing pilot solenoid valve 10 for switching first segment closing cartridge valve 6, second segment closing pilot solenoid valve for switching second segment closing cartridge valve 7 Valve 11, the first emergency cartridge valve 13 connected to the main pressure oil source 12 and the second emergency cartridg...

Embodiment 2

[0044] An overspeed protection and flow control device for a pumped storage power station, comprising a control pressure oil circuit, a first cartridge valve 2 connected to the closing chamber 1 of the main pressure distribution valve through the main oil circuit, and a first cartridge valve 2 connected to the main pressure distribution valve through the main oil circuit. The second cartridge valve 4 on the valve opening chamber 3, the first section closing cartridge valve 6 and the second section closing cartridge valve 7 connected to the servomotor opening chamber 5, also includes the oil return tank 8, the pilot type Electro-hydraulic reversing valve 9, first segment closing pilot solenoid valve 10 for switching first segment closing cartridge valve 6, second segment closing pilot solenoid valve for switching second segment closing cartridge valve 7 Valve 11, the first emergency cartridge valve 13 connected to the main pressure oil source 12 and the second emergency cartridg...

Embodiment 3

[0049] An overspeed protection and flow control device for a pumped storage power station, comprising a control pressure oil circuit, a first cartridge valve 2 connected to the closing chamber 1 of the main pressure distribution valve through the main oil circuit, and a first cartridge valve 2 connected to the main pressure distribution valve through the main oil circuit. The second cartridge valve 4 on the valve opening chamber 3, the first section closing cartridge valve 6 and the second section closing cartridge valve 7 connected to the servomotor opening chamber 5, also includes the oil return tank 8, the pilot type Electro-hydraulic reversing valve 9, first segment closing pilot solenoid valve 10 for switching first segment closing cartridge valve 6, second segment closing pilot solenoid valve for switching second segment closing cartridge valve 7 Valve 11, the first emergency cartridge valve 13 connected to the main pressure oil source 12 and the second emergency cartridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com