Centrifugal water pump formed through spinning-stamping welding of steel plates

A technology of stamping welding and centrifugal water pumps, which is applied in the field of stamping welding centrifugal water pumps and steel plate spinning. It can solve the problems that it is difficult to overcome the radian of the blades on the impeller, the rough environment of the product, and a large amount of labor. It can get rid of casting trachoma, good sealing, and The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

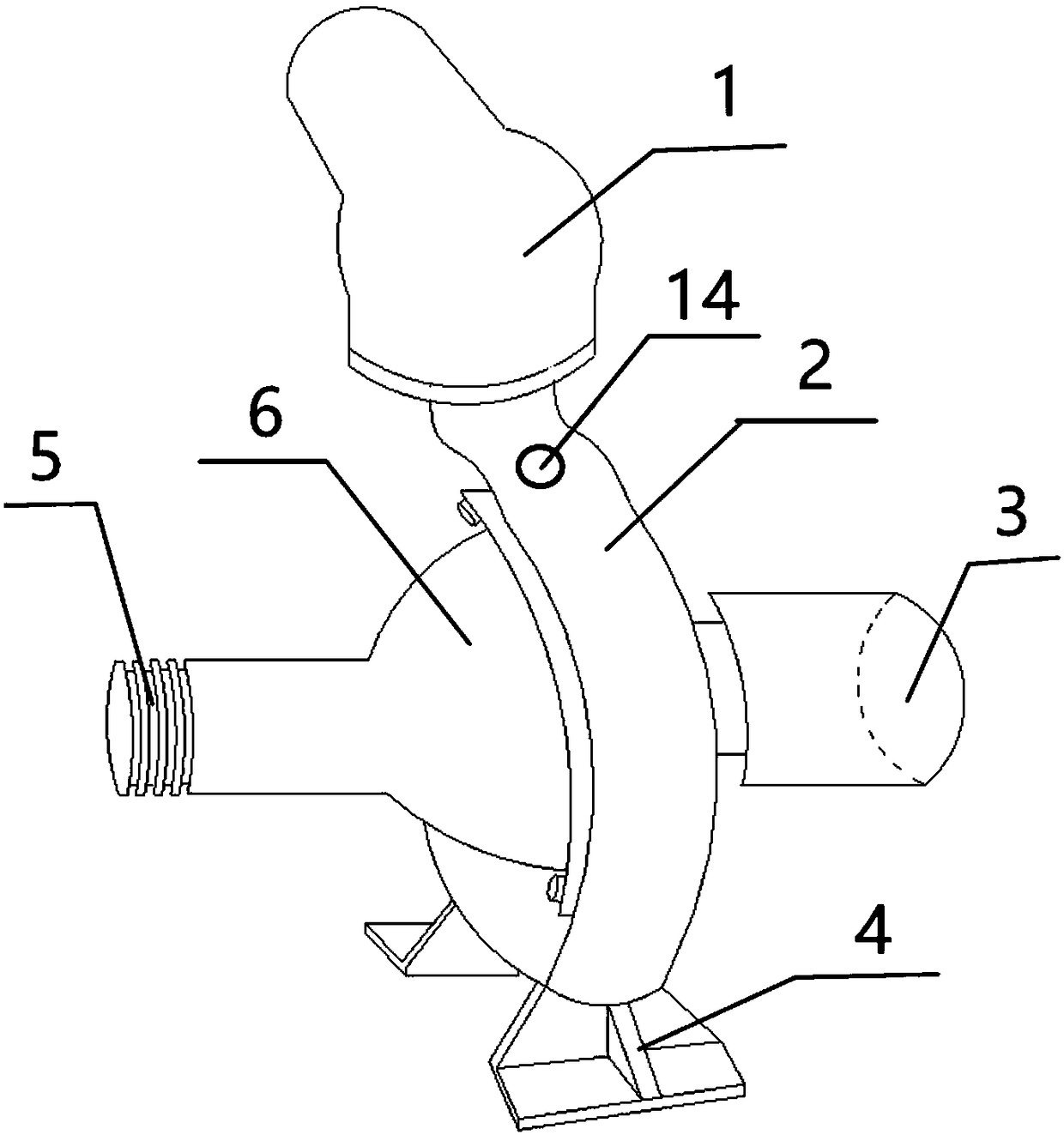

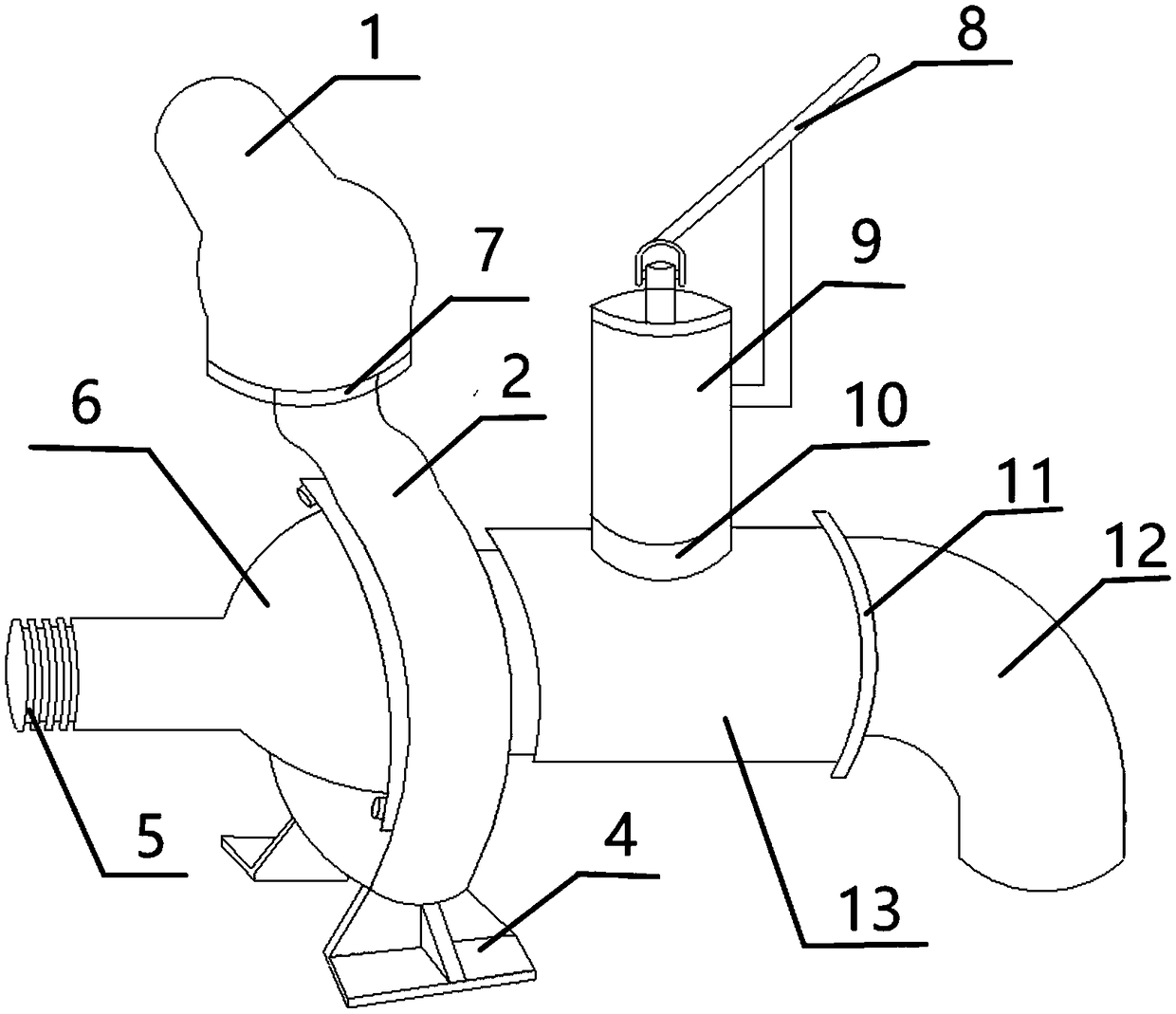

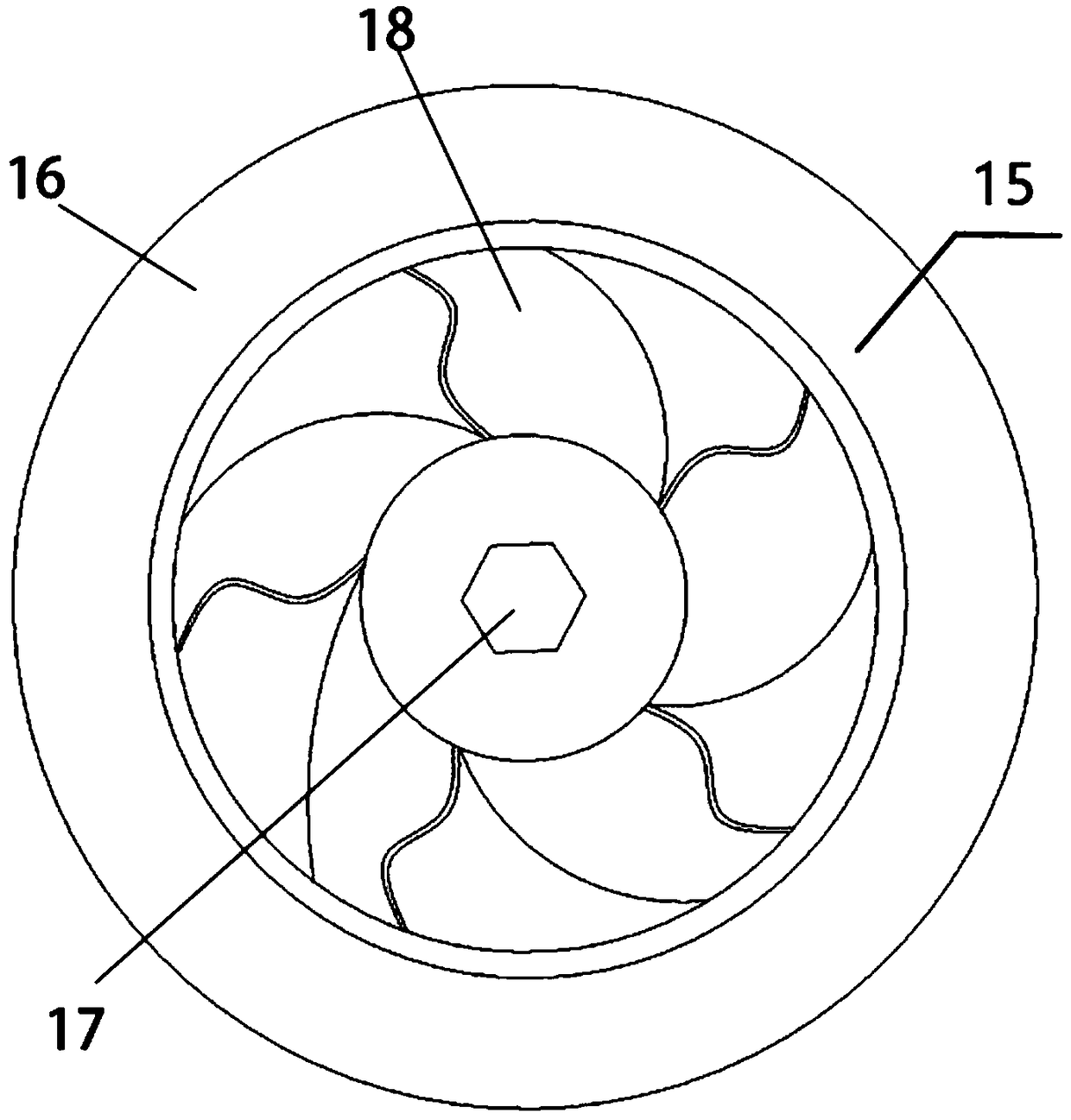

[0033] Such as Figure 1-4 , a steel plate spinning, stamping and welding centrifugal water pump, including two assembly methods: one of them is: steel plate spinning, stamping and welding simple centrifugal water pump, which is composed of a steel plate elbow water outlet 1, a steel plate shell 2, and a steel plate directly Water inlet 3, steel plate pump leg 4, belt pulley 5, steel plate bearing body shell 6, air release valve 14, and steel plate closed impeller 15; It consists of steel plate elbow water outlet 1, steel plate shell 2, steel plate elbow water inlet 12, steel plate pump leg 4, pulley 5, steel plate bearing body shell 6, water outlet check valve 7, water inlet check valve 11, pressure Well head check valve 10, well kill head cylinder body 9, well kill head pressure handle 8, steel plate tee 13, steel plate closed impeller 15, side cover 16, transmission shaft 17, and blade 18 is formed.

[0034]Steel plate spinning, stamping and welding The steel plate closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com