Electric fan head swing angle adjusting device

A technology for regulating devices and electric fans, applied in pump devices, pump control, non-variable pumps, etc., can solve problems such as difficult to use, irregular disorder, high production costs, etc., to improve stability and effectiveness, and prolong work The effect of service life and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with embodiment and accompanying drawing:

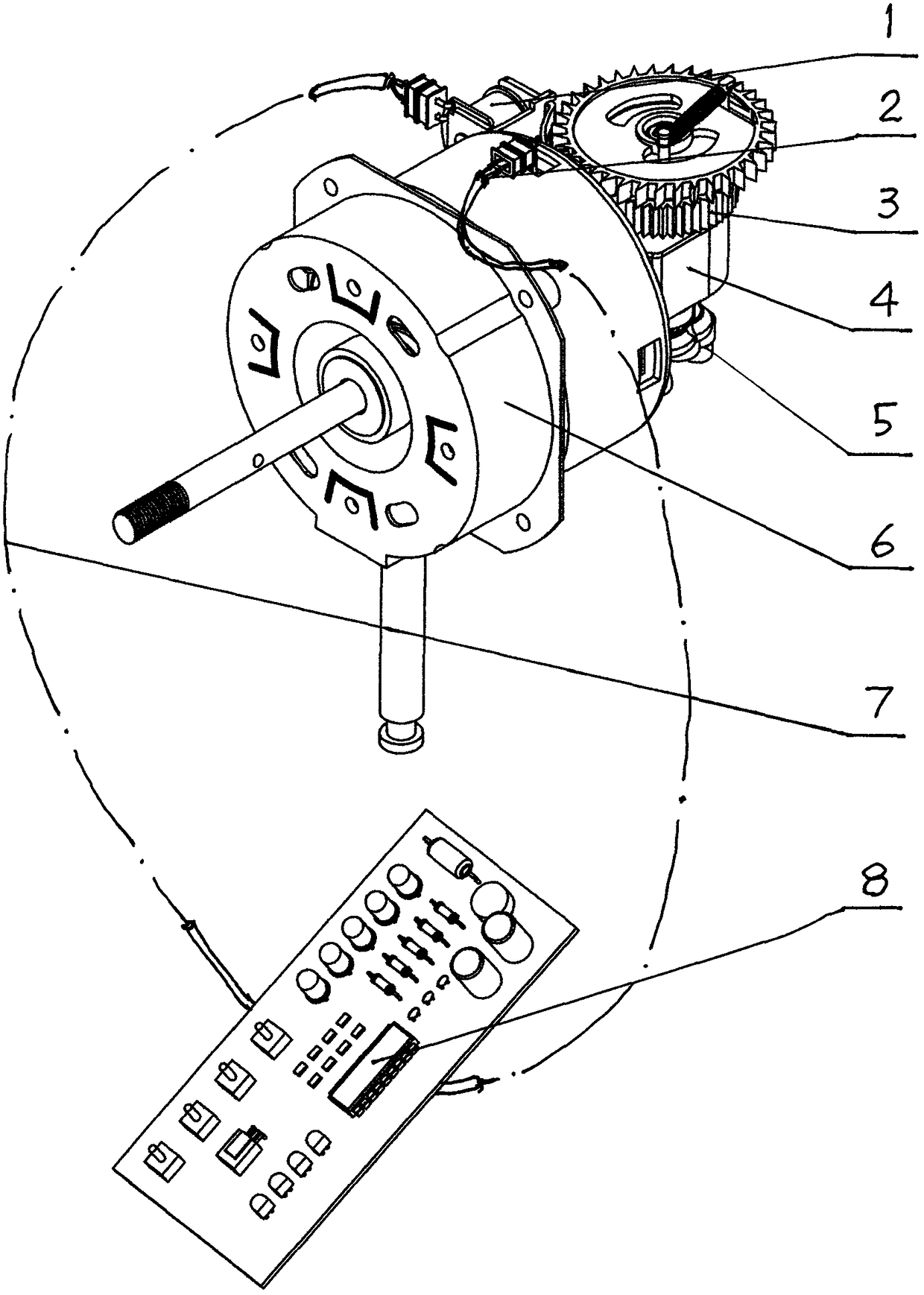

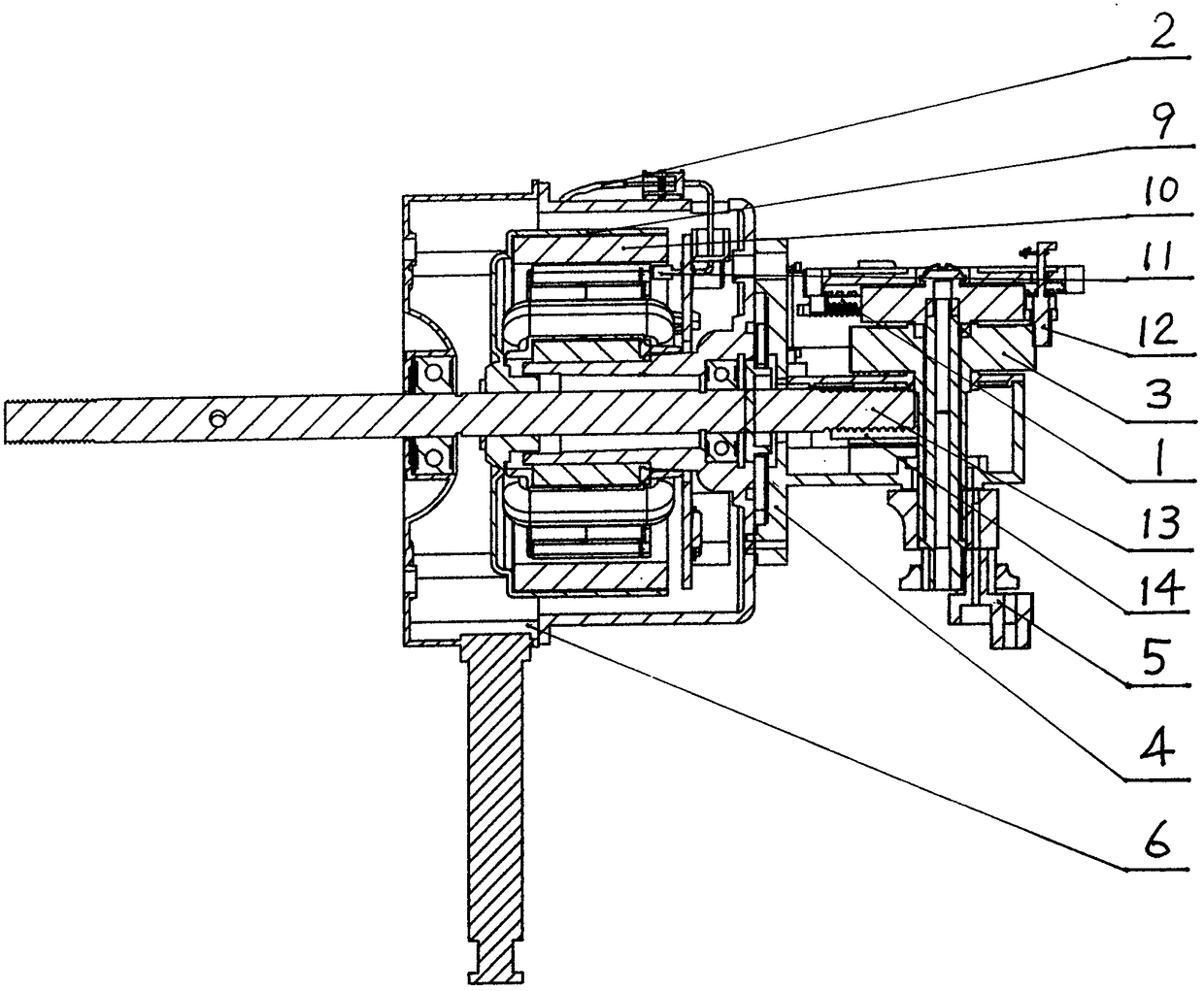

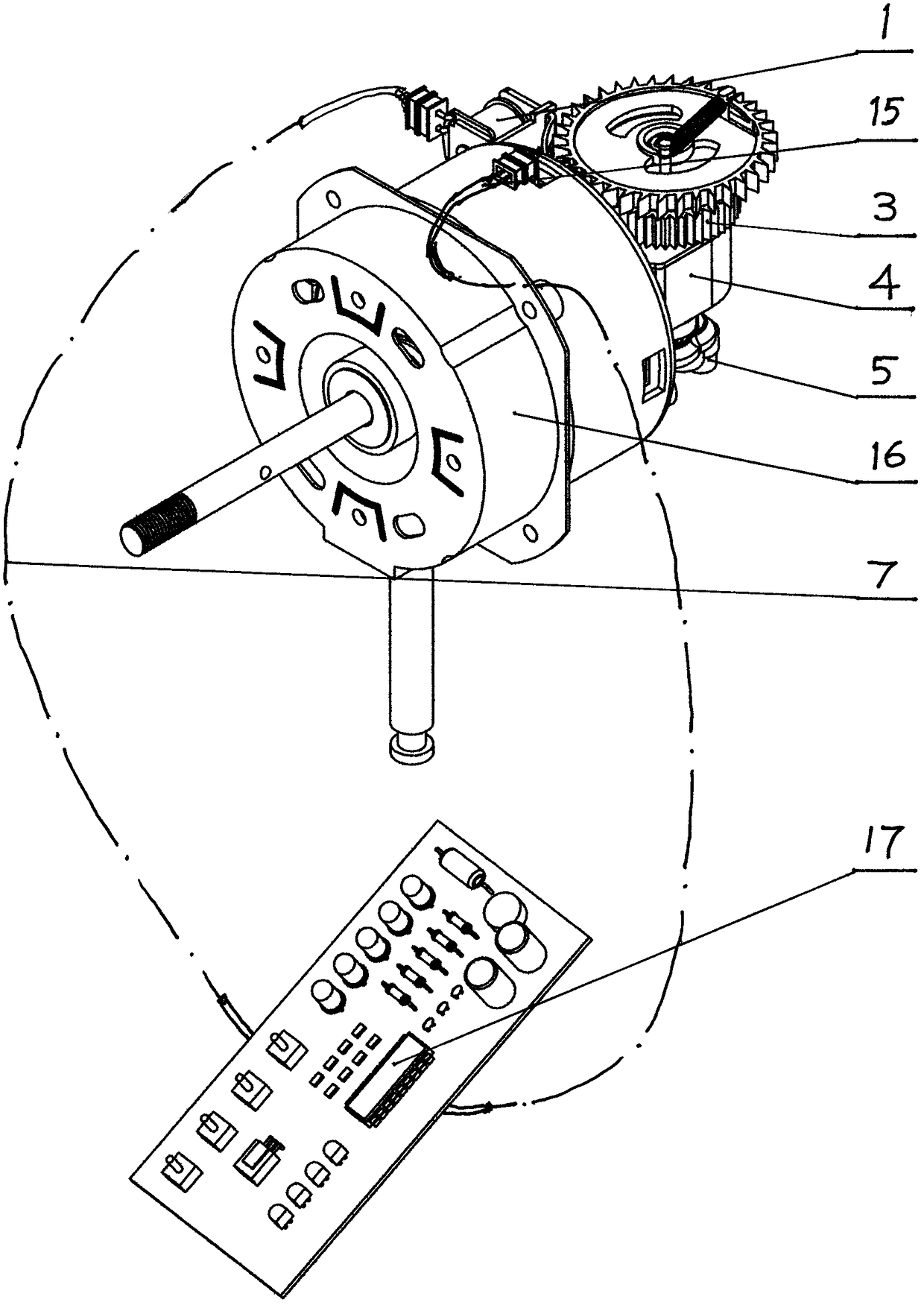

[0023] refer to figure 1 and figure 2 , the present invention comprises outer rotor permanent magnet brushless DC motor 6, a cover is made up of worm screw 13—worm gear 14—worm gear shaft—big gear 3 power transmission mechanism, planetary gear crank 5 mechanism and big gear 3—pawl 12 A variable-angle gearbox 4 composed of a clutch device. The housing of the variable-angle gearbox 4 is equipped with a magnetic attraction device 1. The magnetic attraction device 1 is connected to the angle adjustment control chip 8 through a wire 7. The rotor of the permanent magnet brushless DC motor 6 on the outer rotor 9 is equipped with a permanent magnet 10 magnetic poles, and the permanent magnet 10 magnetic poles become the rotor 9 markers that rotate together with the rotor, and a Hall sensor 11 is placed in the corresponding gap of the permanent magnet 10, and the Hall sensor 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com