A self-tightening disc flange sealing structure

A flange sealing and dish-shaped technology, which is applied in the field of self-tightening dish-shaped flange sealing structure, can solve the problems of high cost, introduction of redundant materials, system safety risks, etc., and achieves simple structure, low processing difficulty, easy installation and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

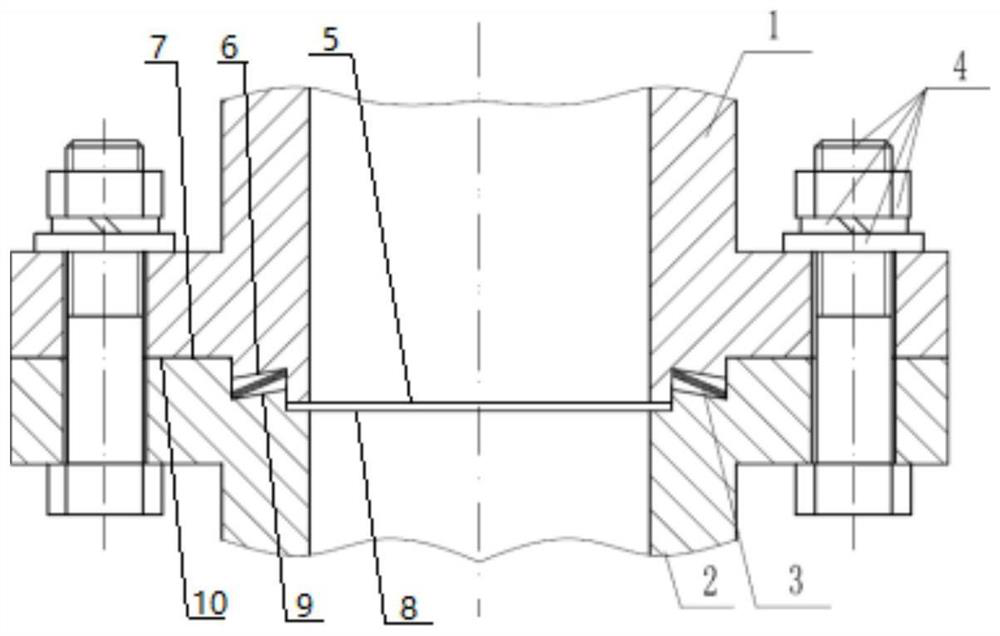

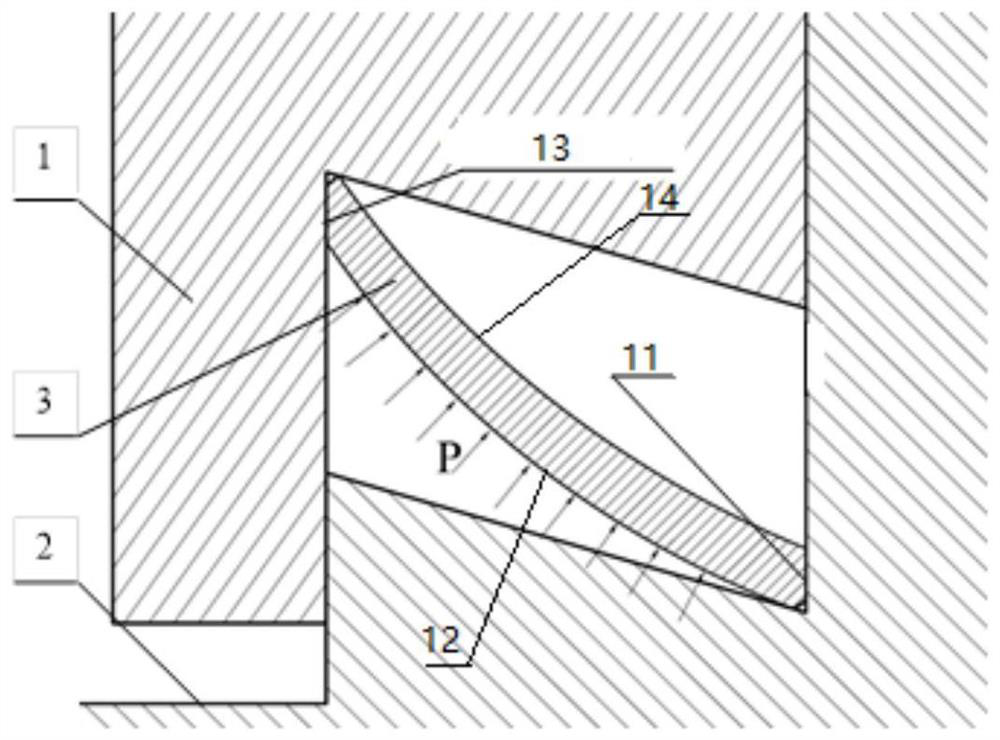

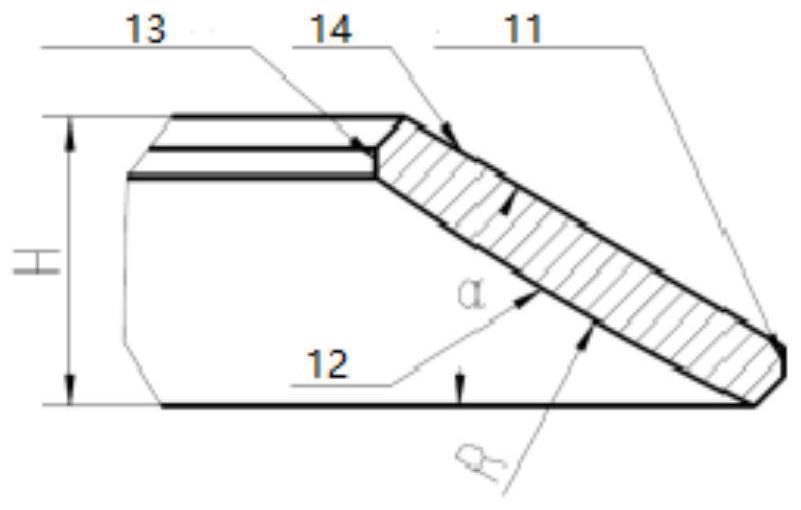

[0024] see figure 1 , a self-tightening disc flange sealing structure of the present invention, comprising a convex flange 1, a concave flange 2, a disc sealing ring 3, and a fastener 4; wherein, the convex flange 1 starts from its central axis There are a central convex surface 5, a first tapered surface 6, and a first mounting surface 7 in order outwardly, and the heights are successively decreased. 9. The height of the second installation surface 10 increases sequentially; the fastener 4 passes through the first installation surface 7 and the second installation surface 10 to fasten the convex flange 1 and the concave flange 2 so that both Concave and convex are matched and have the same central axis; the first tapered surface 6 is opposite to the second tapered surface 9 and forms a closed diamond-shaped space for accommodating the disc-shaped sealing ring 3 .

[0025] The central convex surface 5 is opposite to the central concave surface 8 with a certain gap. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com