Gas stove starting system

A technology for starting a system and a gas stove, applied in the field of gas stoves, can solve the problems of unsuccessful ignition, hidden dangers, poor user experience, etc., and achieves the effects of eliminating hidden dangers, preventing misoperation, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

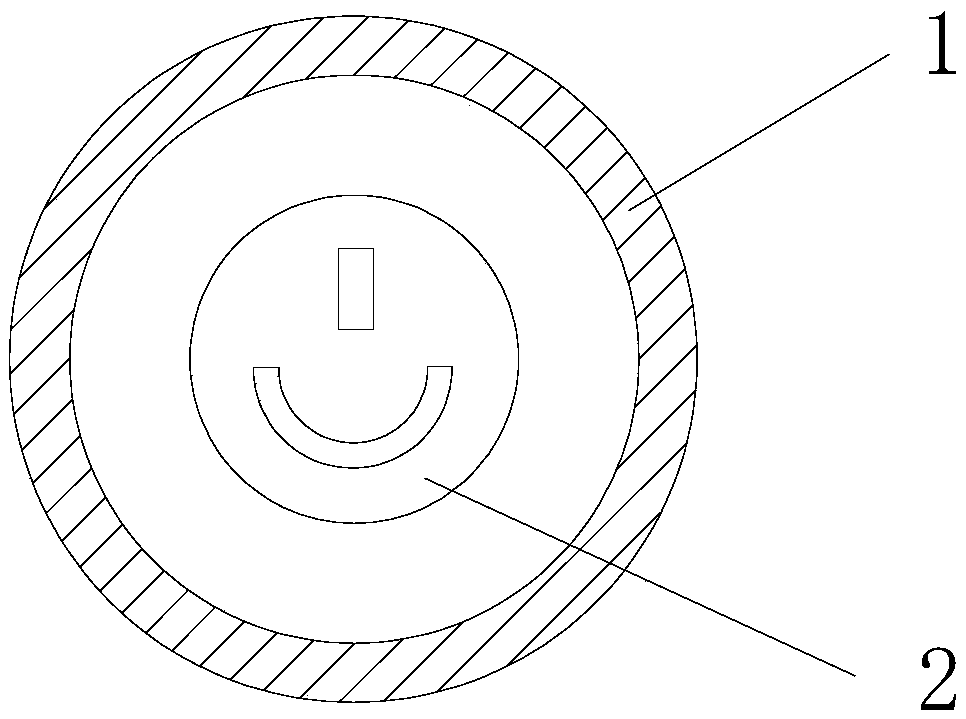

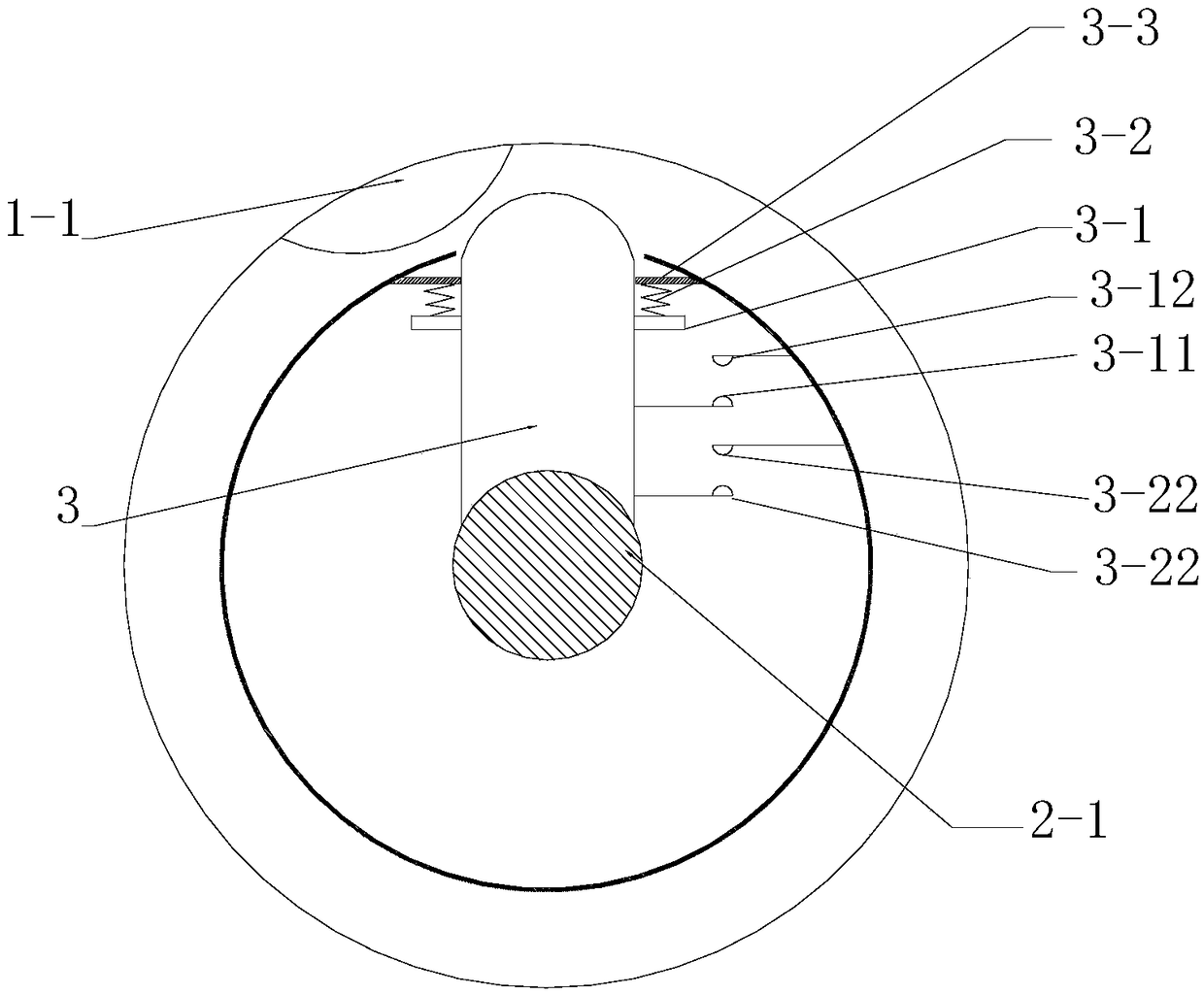

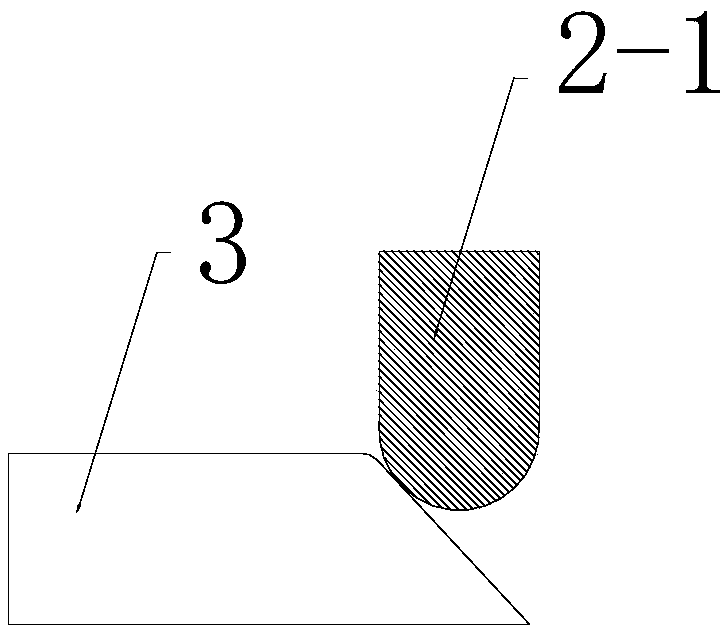

[0036] Such as Figure 1-2 In the example shown above, the gas flow regulating device of the gas stove starting system includes an adjusting knob 1 arranged on the gas stove panel and a gas flow regulating valve connected to the regulating knob inside the gas stove, and the switch on-off device includes a switch button 2 and a gas flow regulating valve on the gas stove. The ignition switch set inside the stove and the valve body switch of the solenoid valve. In this embodiment, the adjusting knob and the gas flow regulating valve are mechanically connected, and the lower part of the adjusting knob is provided with a valve stem. The valve stem and the spool in the regulating valve realize linkage. This realizes the opening and closing of the gas flow regulating valve and the adjustment of the flow rate.

[0037] The adjustment knob 1 is arranged around the outer ring of the switch button 2, and the adjustment knob 1 and the switch button 2 are concentric, and the two are combi...

Embodiment 2

[0045] see Figure 6-7 Compared with Embodiment 1, this embodiment cancels the boss structure of the adjusting knob 1, and the locking device is composed of a semicircular cam 4-1 and an electric lock switch 5 arranged on the side wall of the valve stem 4. 1. The simple mechanical locking device is converted into a control form combining mechanical and electric lock switches. The electric lock switch, ignition switch and valve body switch form a set of control circuit, and the electric lock switch controls the on-off of the whole circuit. In this embodiment, the electric lock switch is a normally open limit switch, that is, when the adjusting knob is at the zero position, the side of the cam is in contact with the electric lock switch, and the electric lock switch is disconnected in the control circuit at this time. Turn on the adjustment knob, the side of the cam is out of contact with the electric lock switch, the locked state is released, and the electric lock switch of th...

Embodiment 3

[0049] The difference between this embodiment and Embodiment 2 is that the mechanical adjustment knob is replaced by a touch screen button, the gas flow adjustment valve is converted from a manual control form to an electronically controlled proportional valve, and a minimum control current is set for the electronically controlled proportional valve. The minimum control current is introduced into the control circuit of the electric lock switch and the switch on-off device. When the electronically controlled proportional valve is turned on, the minimum control current conducts the electric lock switch, the switch on-off device is unlocked, and the touch screen button of the switch on-off device is clicked, the ignition switch and valve body switch in the control circuit are turned on, and the gas stove is turned on . When the electric control proportional valve is closed, the gas stove is turned off, the electric lock switch detects no current signal, cuts off the control circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com