A kind of constrained ceramic-metal composite bulletproof armor plate and its preparation method

A metal cladding and restraining plate technology, applied in protective equipment, armor plate structure, armor and other directions, can solve the problems of inconvenient control and design of compression prestress, weakening the bulletproof effect of bulletproof plate, complicated operation of existing means, etc. Processing and design, uniform distribution, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]A constrained ceramic-metal composite bulletproof armor plate and a preparation method thereof of the present invention, first cut a circular hole on the metal constrained plate; then heat the metal constrained plate, fill the circular hole with a cylindrical shape with a diameter slightly larger than the initial diameter of the circular hole The ceramic block is then cooled; finally, the adhesive is applied to the metal back plate, and the metal constraining plate and the ceramic are bonded; the specific steps are as follows:

[0044] S1. Laser line cutting is used to drill circular holes on the metal constraining plate 2, and the surface roughness R of the inner holes is controlled during the cutting process. a ≤3.2μm;

[0045] S2, prepare cylindrical ceramic block 3, grind the surface of cylindrical ceramic block 3 to make its surface roughness R a ≤3.2μm;

[0046] The diameter of the cylindrical ceramic block 3 is larger than the diameter of the round hole of the m...

Embodiment 1

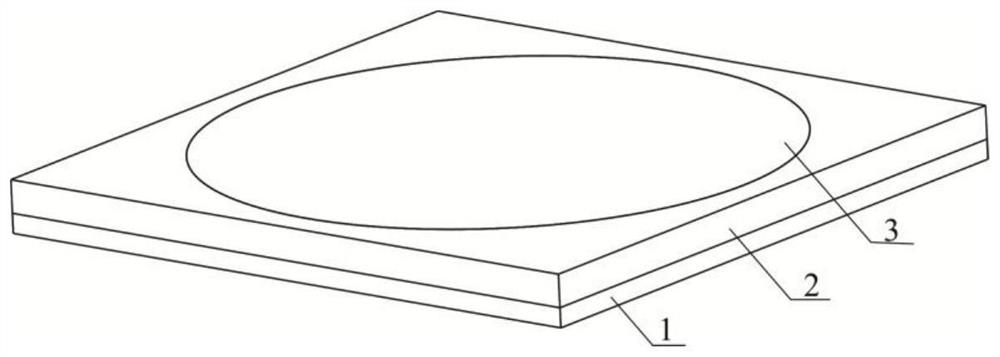

[0054] see figure 1 ;

[0055] (1) Take a piece of TC4 titanium alloy plate whose length, width, and height are 120mm, 120mm, and 6mm respectively, and use laser cutting to cut a circular hole with a diameter of 99.6mm in the center of the TC4 titanium alloy plate. The cutting process controls the surface of the inner hole Roughness R a ≤3.2μm;

[0056] (2) Prepare a cylindrical boron carbide ceramic block with a diameter of 100 mm and a height of 6 mm, and grind the surface of the ceramic block to make its surface roughness R a ≤3.2μm;

[0057] (3) Put the cut TC4 titanium alloy constraining plate into the muffle furnace, raise the temperature at a rate of 25°C / min, and keep it warm for 2min when the temperature reaches 900°C; then place the boron carbide at room temperature in the muffle furnace The ceramic block is placed in the circular hole of the TC4 titanium alloy constrained plate after high temperature expansion; the muffle furnace is closed to cool the TC4 titani...

Embodiment 2

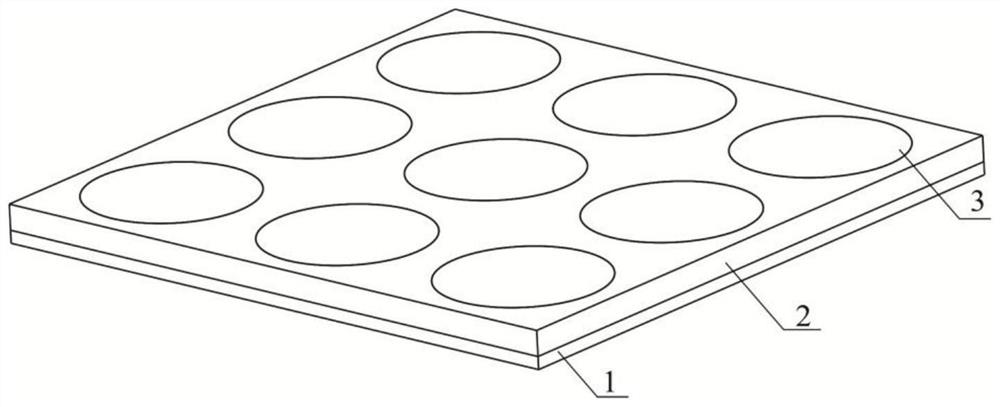

[0060] see figure 2 ;

[0061] (1) Take a 40CrNiMo steel plate whose length, width, and height are 150mm, 150mm, and 6mm respectively, and use wire cutting to cut three rows and three columns of nine circular holes with a diameter of 39.8mm on the 40CrNiMo steel plate. The center is aligned, the distance between the center of the circular hole is 50mm, and the surface roughness R of the inner hole is controlled during the cutting process a ≤3.2μm;

[0062] (2) Prepare 9 cylindrical silicon carbide ceramic blocks with a diameter of 40 mm and a height of 6 mm, and grind the surface of the ceramic block to make its surface roughness R a ≤3.2μm;

[0063] (3) Put the cut 40CrNiMo steel restraint plate into the muffle furnace, raise the temperature at a rate of 40°C / min, and keep it warm for 3min when the temperature reaches 850°C; then carbonize the 9 pieces at room temperature in the muffle furnace The silicon ceramic block is placed in the circular hole of the 40CrNiMo steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com