A case of a power capacitor compensation device

A technology of power capacitors and compensation devices, which is applied in the substation/power distribution device shell, reactive power compensation, substation/switchgear board/panel/desk, etc., which can solve the problem of increasing costs and difficulties and affecting the stability of power capacitor compensation devices , inconvenient maintenance and other problems, to reduce quality risks, improve installation efficiency, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

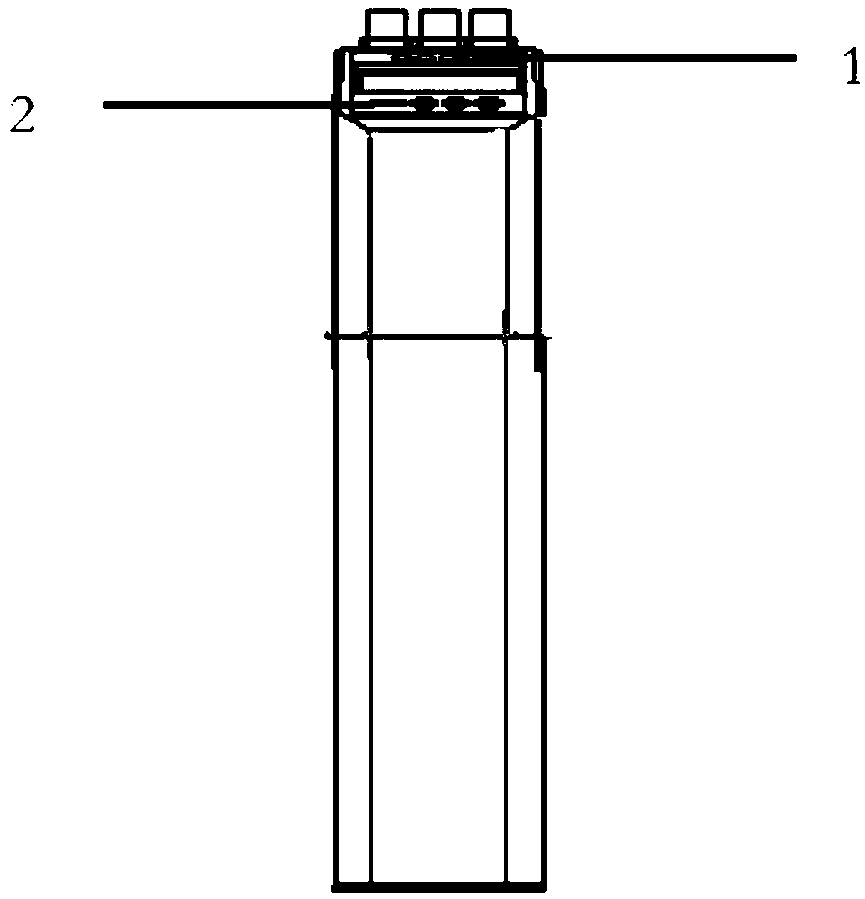

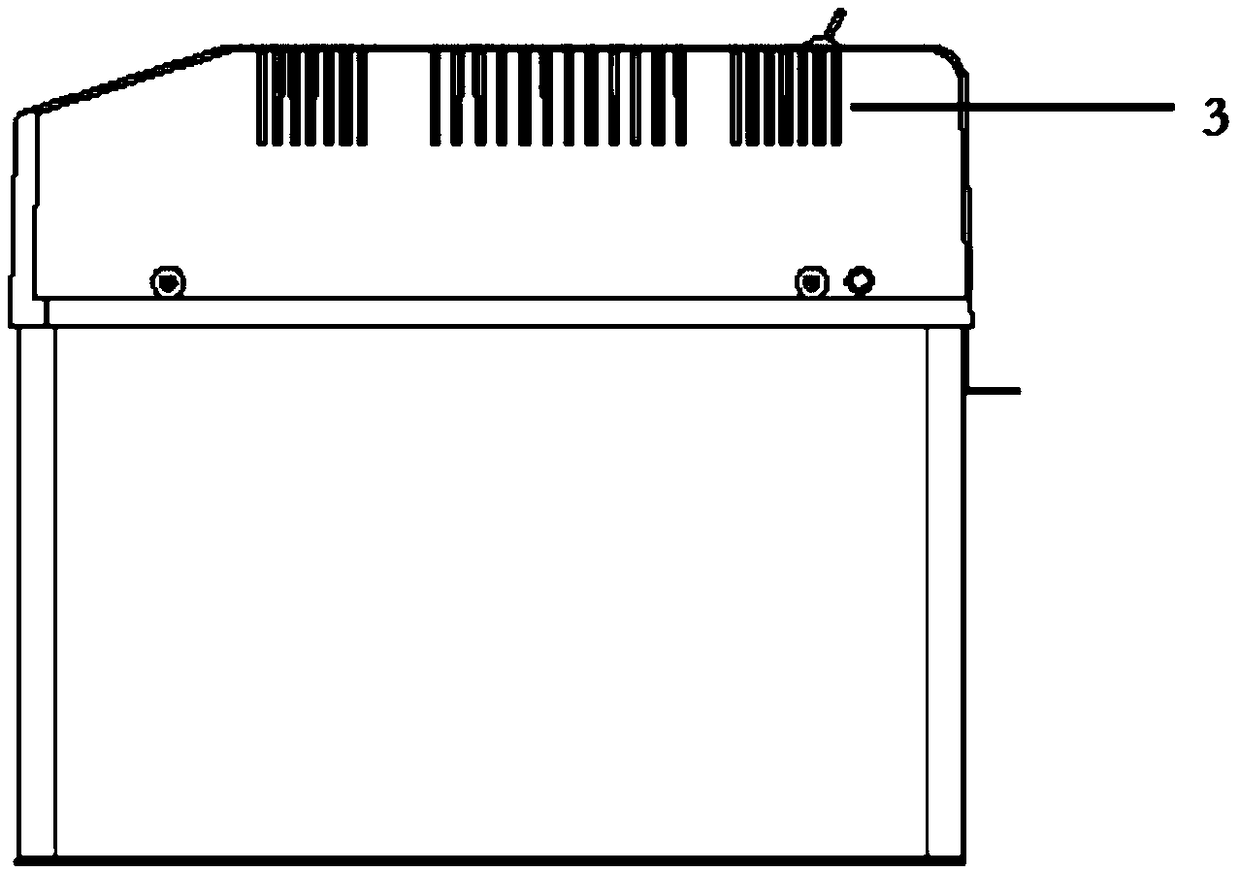

[0050] The invention relates to a shell of a power capacitor compensation device, such as figure 1 As shown, the circular hole on the upper part of the display part is the position of the indicator light 1, and the circular and square hole on the lower part of the display part is the position of the control button 2. Such as figure 2 and 4 As shown, there are vertical strip-shaped cooling slots 3 on both sides of the outer casing of the power capacitor compensation device, as shown in image 3 and 5 As shown, the 55mm*46mm opening at the upper end of the casing tail is used to install the miniature circuit breaker 4, and the rear end of the opening of the miniature circuit breaker 4 has three oval openings with a distance of 18mm to facilitate the screwdriver to enter and tighten when the external power supply line is connected to the miniature circuit breaker. screw. There are three openings of 8mm*13mm in the upper part of the rear end of the cover. From left to right, ...

Embodiment 2

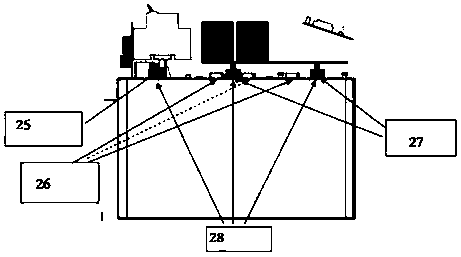

[0076] Such as Figure 6 and 8 As shown, this intelligent compensation terminal is a three-phase co-compensation compensation device. The optional capacity of the co-compensation capacitor body is 2.5Kvar-40Kvar, and each phase can independently compensate reactive power. Installed in the complete set of cabinets in the distribution transformer area according to the load ratio to form a centralized compensation of reactive power in the low-voltage power grid. The control system hardware includes a main board 21, a function board 18 and a switch board 23. Among them, the switch board used for capacitor switching is vertically fixed on the main board in the form of upper and lower rows, and the function board is vertically fixed at the tail of the capacitor board to ensure the maximum utilization of space. At the same time, the strong current and weak current signals are respectively arranged on the front and rear sides of the motherboard, and a safe distance should be ensured....

Embodiment 3

[0078] Such as Figure 4 and 9 As shown, the terminal shell is divided into the black injection molding part on the capacitor body and the capacitor upper cover. The capacitor body and the upper cover of the capacitor are fixed by screws around the capacitor, and the black injection molded parts on the body are supported by copper pillars to fix the control unit circuit board and capacitor. The front layout of the shell mainly includes windows such as liquid crystal display, button 2, indicator light 1, and miniature circuit breaker 4. The rear part includes two RJ45 interfaces, three-phase four-wire interfaces, and external current measurement terminal interfaces. The round hole on the left side is the N-phase terminal. interface. Vertical strip-shaped slot holes are opened on both sides of the upper cover to ensure the heat dissipation of the capacitor. The total size of the upper cover (length*width*height) is 345mm*78mm*100mm, and it is installed directly above the capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com