Plug-in type high-temperature-resistant ablation prefabricated part for flow guide groove of launching station and construction method of fire-resistant protective layer

A construction method and technology of diversion grooves, which are applied to rocket launchers, manufacturing tools, ceramic molding machines, etc., can solve problems such as poor high-temperature ablation resistance, damaged structures, and structural damage, and achieve excellent high-temperature ablation resistance , Strong environmental adaptability and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

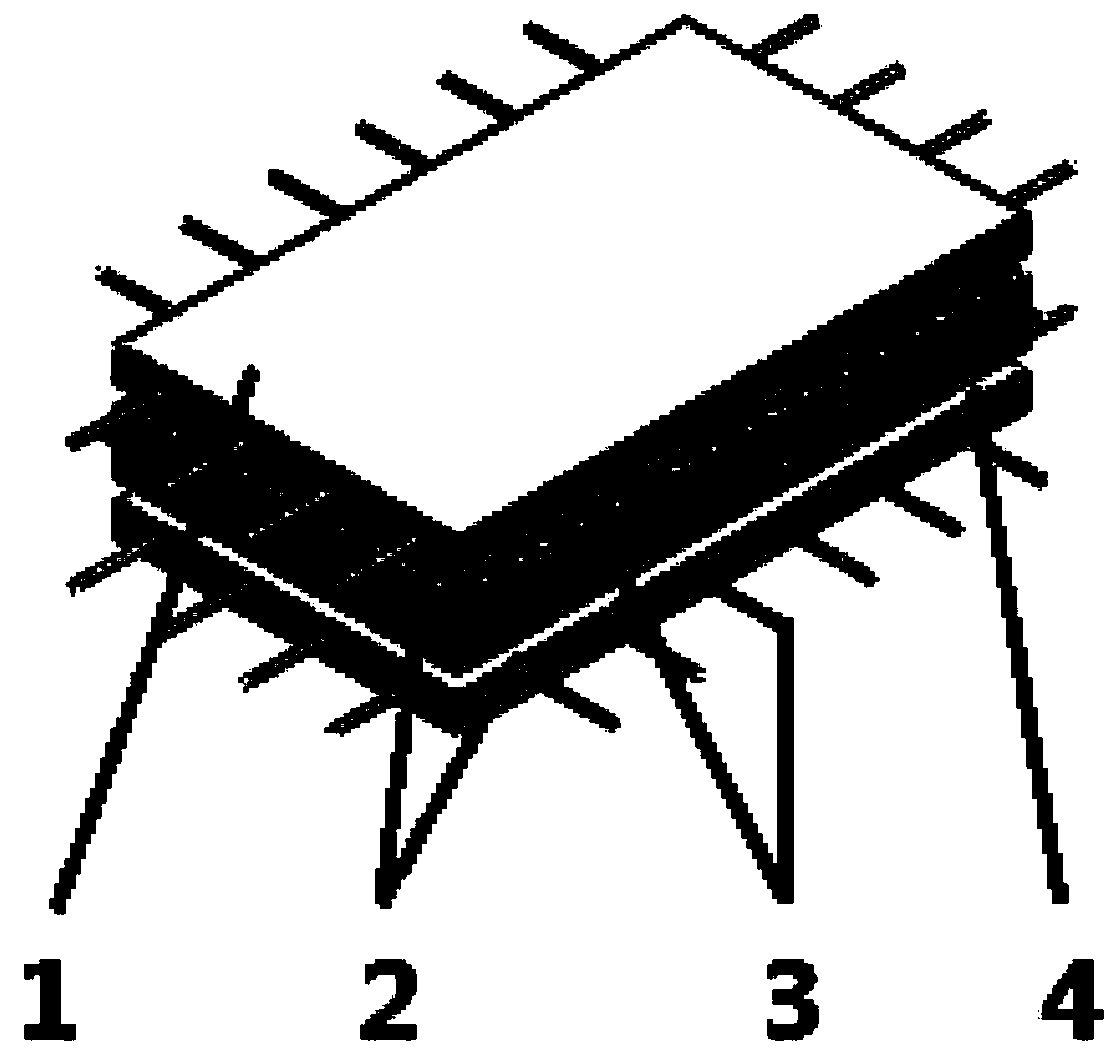

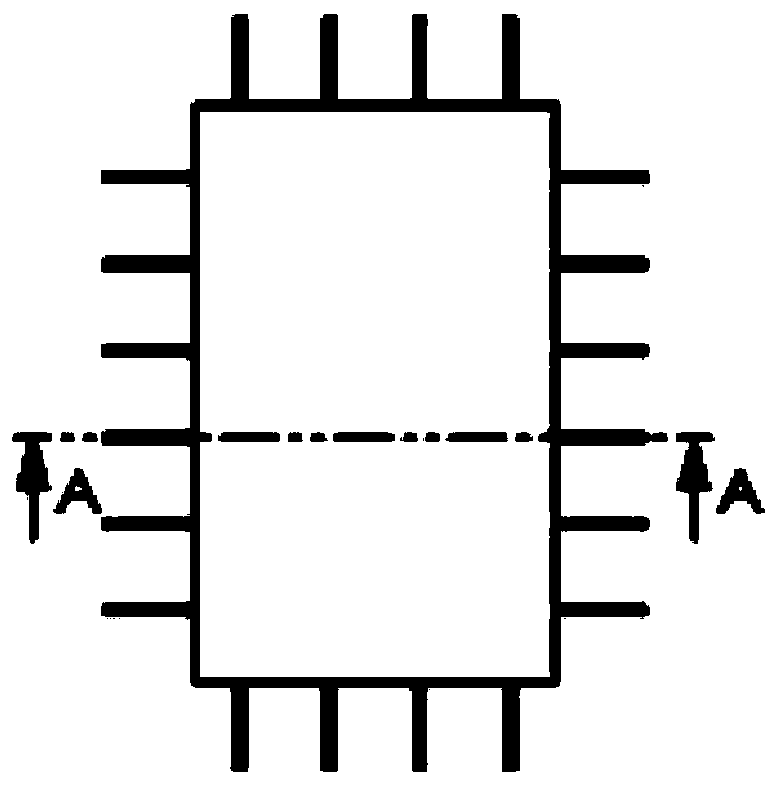

[0031] Such as Figure 1~5 As shown, a ready-to-install high-temperature ablation-resistant prefabricated part for the diversion tank of the launching station, the prefabricated part includes a high-temperature ablation-resistant main body 1 made of refractory castable, and the high-temperature ablation-resistant main body is provided with a vacancy Structure 2 and upper and lower layers of reinforcement mesh 3; the reinforcement mesh 3 is composed of criss-cross reinforcement rods embedded in the refractory castable and extending beyond the refractory castable; the vacancy structure 2 is located in the upper and lower layers of reinforcement Between the nets 3, the vacancy structure 2 is composed of regular grooves 4 formed by vacancies inside the refractory castable. The vacancy structure 2 includes upper and lower layers of grooves 4, the cross section of the groove 4 is trapezoidal or triangular, and the edge of the cross section of the vacancy structure 2 is a continuous ...

Embodiment 2

[0034] This embodiment is the same as Embodiment 1 except that the vacancy structure is changed.

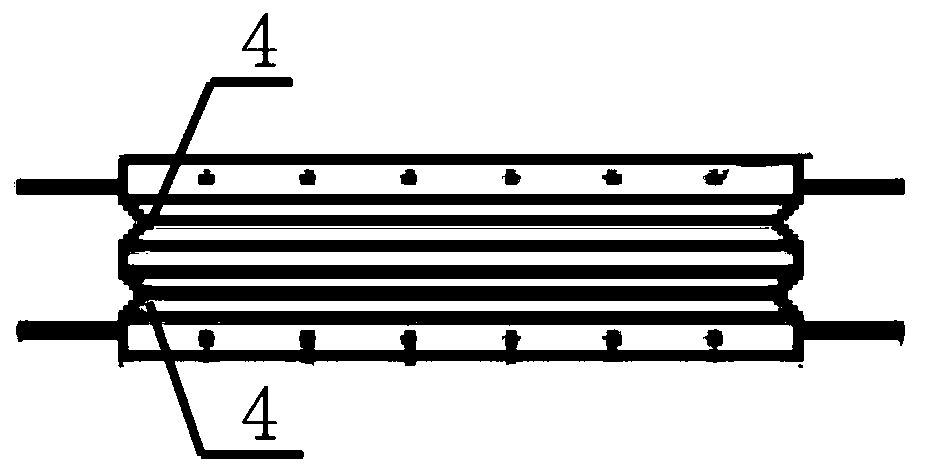

[0035] Such as Figure 6~8 As shown, the cross section of the groove 4 is rectangular, and a T-shaped anchoring structure is arranged between the upper and lower layers of grooves.

Embodiment 3

[0037] A construction method for fire-resistant protective layer of a diversion channel at a launch station, in which the prefabricated part described in embodiment 1 or embodiment 2 is arranged at a certain position in the diversion channel, and the refractory castable around the prefabricated part is cast in place, and the reinforcement mesh of the prefabricated part 3 is docked with the steel bars of the surrounding diversion channel matrix, and the void structure 2 in the prefabricated part is riveted with the cast-in-place refractory castable to complete the structural integration of the diversion channel.

[0038] The prefabricated parts are prefabricated by pouring in the factory. The specific preparation method is: 1) Make the mold according to the drawing, 2) Place the steel mesh in the mold, and pre-embed the riveting structure corresponding to the required vacant structure shape, 3) According to the Technical solution Prepare refractory castables, 4) carry out pourin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com