Oil slick collector and oil slick collecting method

A collector and oil slick technology, which is applied in chemical instruments and methods, separation methods, grease/oily substance/float removal devices, etc., can solve the problems of inefficient and clean oil-water separation, achieve efficient oil slick collection work, strengthen The effect of cleanliness and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

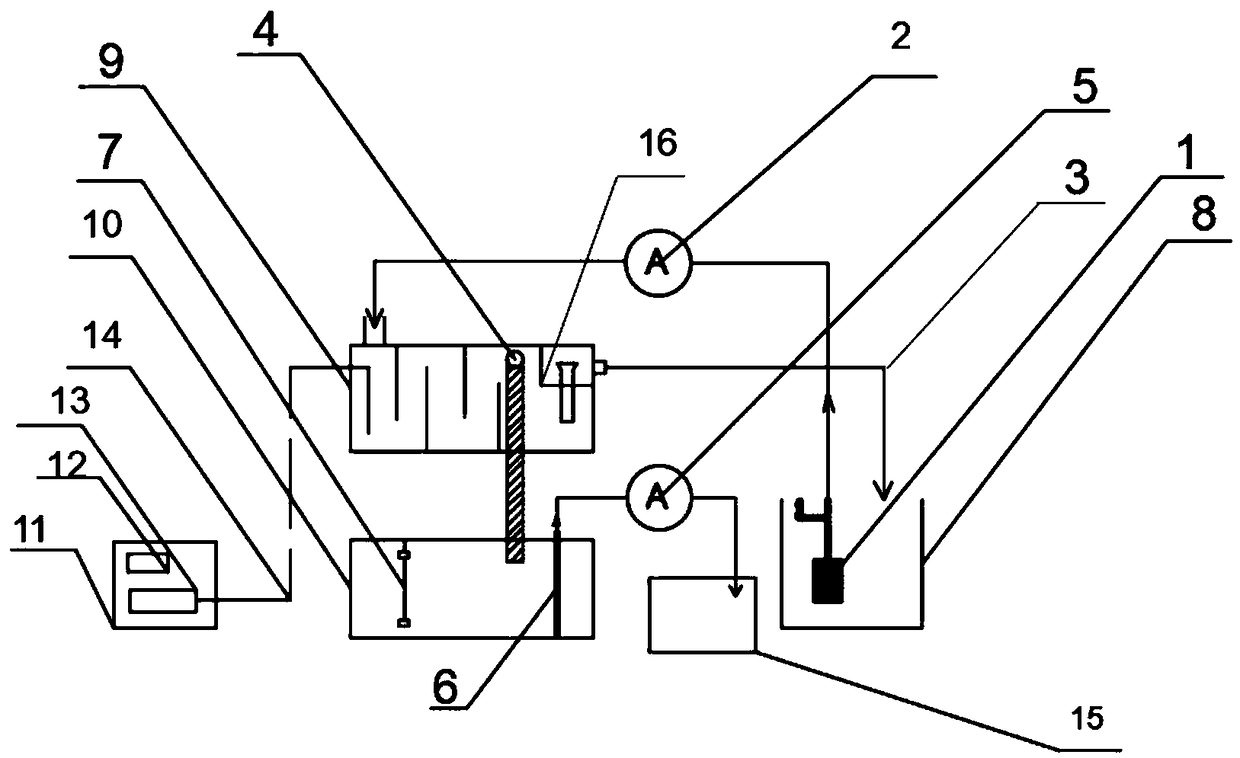

[0042] like figure 1As shown, a floating oil collector 1 includes a water inlet diaphragm pump 2, and the water inlet diaphragm pump 2 is provided with an oil-water separation box 9, an oil outlet pipe 4, a water outlet pipe 3, an oil separation tank 16, a waste water tank 8, and a floating oil tank. Oil collection buoy, collecting waste oil tank 10. Wherein, the floating oil collection buoy is set in the waste water tank 8, the two ends of the water inlet diaphragm pump 2 are connected to the oil-water separation box 9 and the oil floating collection buoy, the oil outlet pipe 4 and the oil separation chamber 16 are arranged in the oil-water separation box 9, and the water outlet pipe 3 Both ends are connected to the waste water pool 8 and the oil separation tank 16, and the oil outlet pipe 4 is connected to the waste oil tank 10 for collecting. First start the water-inlet diaphragm pump 2, and directly suck the waste liquid of the oil-water mixture in the waste water pool 8 ...

Embodiment 2

[0061] A method for collecting slick oil, comprising the following steps:

[0062] Collect the oil slick, start the water inlet diaphragm pump 2, and use the oil slick collection buoy 1 to directly extract the oil slick in the waste water tank 8 into the oil-water separation tank 9;

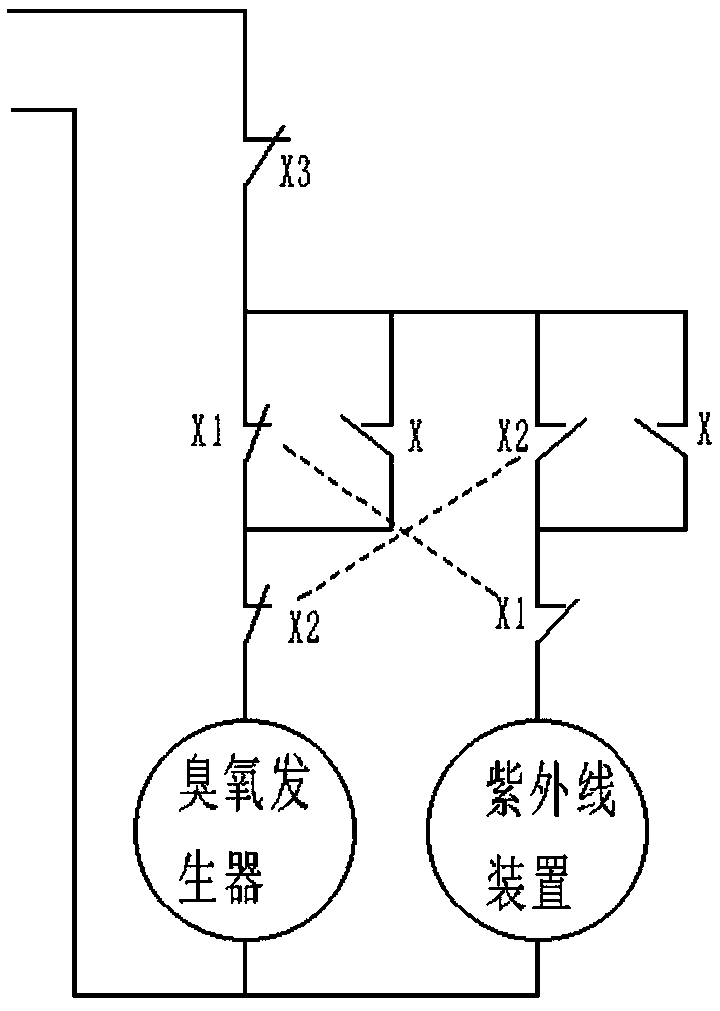

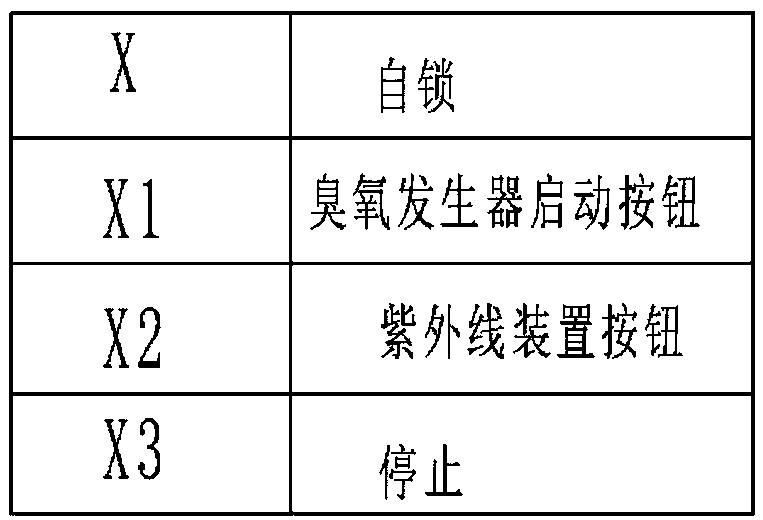

[0063] Sterilization, start the ozone generator 13, and the generated ozone enters the oil-water separation box 9 along the delivery pipe 14 to effectively sterilize the oil and water;

[0064] Switch the sterilization device, according to the requirements of the ozone concentration, the ozone sensor transmits the information to the circuit control system, if the standard is met, the ozone generator 13 continues to operate, if not, then switch to the ultraviolet sterilization device for effective sterilization;

[0065] Water separation, when the oil and water in the oil-water separation tank 9 reach a certain height, the oil separation chamber 16 isolates the floating oil, and then the water in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com